Abstract

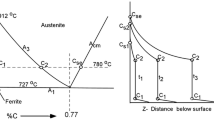

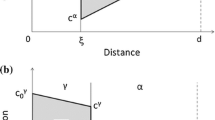

Mathematical models have been developed for simulating the carburization process. One model simulates carburization in low alloy steels where temperature, time, surface carbon content, and diffusion coefficient vary during the process. Two step and vacuum carburization are among the treatments considered. The other model simulates the ef-fect of major ternary alloying additions such as Mn, Cr, Ni and Si during carburization. The importance of the off diagonal or cross diffusion coefficientD 312 on carbon diffusion is calculated. The Crank-Nicolson finite difference equations are used to provide numeri-cal stability and flexability. Calculated carbon profiles for low alloy steels were com-pared with experimental data available in the literature. Agreement between calculated and measured data was very good. Chromium and silicon have large cross coefficient ef-fects and it is predicted that they have a large influence on the amount of carburization which will occur. Experimental data for carburization treatments of Fe-C-Cr alloys are in excellent agreement with model predictions of major increases in effective surface carbon content and the formation of carbides in austenite at the carburization tempera-ture. These computer models are relatively easy to apply and can be used to design car-burization treatments for specific alloy steels.

Similar content being viewed by others

References

R. W. Gurry:Trans. AIME, 1950, vol. 188, p. 671.

F. J. Harvey:Met. Trans. A, vol. 9A, pp. 000–00.

C. Wells and R. F. Mehl:Trans. AIME, 1940, vol. 140, p. 279.

Metals Handbook, 8th ed., vol. 8, p. 276, American Society for Metals, 1973.

F. E. Harris:Metals Handbook, 1948 edition, p. 678, American Society for Metals.

A. G. Guy:Iron Age, 1949, Jan. 27, vol. 163, p. 74.

Metals Handbook, 8th ed., vol. 2, p. 102, American Society for Metals, 1964.

C. Bolze, D. E. Coates and J. S. Kirkaldy:Trans. ASM, 1969, vol. 62, p. 794.

D. V. von Rosenberg:Methods for the Numerical Solution of Partial Differen-tial Equations, American Elsevier Publishing Co., New York, 1969.

L. Onsager:Ann. N. Y. Acad Sci., 1945, vol. 46, p. 241.

J. S. Kirkaldy:Adv. Mater. Res., 1970, vol. 4, p. 55.

Metals Handbook, 8th ed., vol. 2, p. 99, American Society for Metals, 1964.

Metals Handbook, 8th ed., vol. 2, p. 106, American Society for Metals, 1964.

Metals Handbook, 8th ed., vol. 2, p. 76, American Society for Metals, 1964.

P. C. Jindal:MetalProgr, 1973, April, p. 78.

M. L. Wayman and J. T. Gray:Acta Met., 1974, vol. 22, p. 349.

J. Ferrante: NASA, TN D-7789, 1974.

R. Chatterjee-Fischer:Met. Trans. A, vol. 9A, pp. 000–00.

L. C. Brown and J. S. Kirkaldy:Trans. TMS-AIME, 1964, vol. 230, p. 223.

J. I. Goldstein, R. E. Hanneman, and R. E. Ogilvie:Trans. TMS-AIME, 1965, vol. 233, p. 812.

K. Nohara and K. Hirano:Proc. Intl Conf. © and Technology Iron and Steel, p. 1267, Tokyo, 1971.

A. W. Bowen and G. W. Leak:Met. Trans., 1970, vol. 1, p. 1695.

M. A. Krishtal and A. M. Morova:Fiz. Tekhn, Navki., 1967, vol. 1, p. 93.

“Carburized Nickel Alloy Steels Data Book, Section 2-B,” p. 2-B, Inter-national Nickel Company, Inc., 1975.

G. K. Manning:Trans. ASM, 1943, vol. 31, p. 8.

Author information

Authors and Affiliations

Additional information

Formerly Graduate Assistant, Metallurgy and Materials Engineering Department, Lehigh University.

This paper is based on a presentation made at a symposium on “Carburizing and Nitriding: Fundamentals, Processes and Properties” held at the Cincinnati Meeting of the Metallurgical Society of AIME, November 11 and 12, 1975 under the sponsorship of the Heat Treatment Committee.

Rights and permissions

About this article

Cite this article

Goldstein, J.I., Moren, A.E. Diffusion modeling of the carburization process. Metall Trans A 9, 1515–1525 (1978). https://doi.org/10.1007/BF02661934

Issue Date:

DOI: https://doi.org/10.1007/BF02661934