Abstract

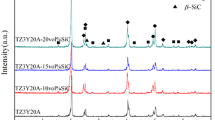

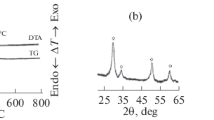

ZrO2-mullite nano-ceramics were fabricated by in-situ controlled crystallizing from SiO2-Al2O3-ZrO2 amorphous bulk. The thermal transformation sequences of the SiO2-Al2O3-ZrO2 amorphous bulk were investigated by X-ray diffraction, infrared spectrum, scanning electron microscope and differential scanning calorimetric. And the mechanical properties of the nano-ceramics were studied. The results show that the bulks are still in amorphous state at 900 °C and the t-ZrO2 forms at about 950 °C with a faint spinel-like phase which changes into mullite on further heating. ZrO2 and mullite become major phases at 1 100 °C and an amount of m-ZrO2 occur at the same time. The sample heated at 950 °C for 2 h and then at 1 100 °C for 1 h shows very dense and homogenous microstructure with ball-like grains in size of 20–50 nm. With the increase of crystallization temperature up to 1 350 °C, the grains grow quickly and some grow into lath-shaped grains with major diameter of 5 μm. After two-step treatment the highest micro-hardness, flexural strength and fracture toughness of the samples are 13.72 GPa, 520 MPa and 5.13 MPa·m1/2, respectively.

Similar content being viewed by others

References

SCHNEIDER H, OKADA K, PASK J A. Mullite and Mullite Ceramics[M]. New York: J Wiley, 1994: 140–146.

KHOR K A, LI Y. Crystallization behaviors in the plasma-spheroidized alumina/zircon mixtures[J]. Materials Letters, 2001, 48(1): 57–63.

LATHABAI S, HAY D G, WAGNER F, et al. Reaction-bonded mullite/zirconia composites[J]. J Am Ceram Soc, 1996, 79(1): 248–256.

GARRIDO L B, AGLIETTI E F. Reaction-sintered mullite-zirconia composites by colloidal processing of alumina-zircon-CeO2 mixtures[J]. Mater Sci Eng, 2004, A369(1/2): 250–257.

TAN Ye-fa, WANG Yao-hua, YU Ai-bing, et al. Friction and wear behaviors of zirconia toughened mullite composites[J]. Tribology, 2000, 20(2): 94–97.

JIN Xi-hai, GAO Lian, KAN Yan-mei, et al. Influence of Nb2O5 on the mechanical performances and toughening mechanism of ZrO in ZTM-Al2O3[J]. Journal of Inorganic Materials, 2000, 15(6): 1009–1014. (in Chinese)

ZHAO Shi-ke, HUANG Yong, WANG Chang-an, et al. Effect of mullite seeding on Microstructure of reaction-sintered mullite/Zirconia multiphase ceramics[J]. Journal of the Chinese Ceramic Society, 2002, 30(5): 589–592.(in Chinese)

KHOR K A, YU L G, LI Y, et al. Spark plasma reaction sintering of ZrO2—mullite composites from plasma spheroidized zircon/alumina powders[J]. Mater Sci Eng, 2003, A339(1/2): 286–296.

TAN Xiao-ping, LIANG Shu-quan, LI Shao-qiang, et al. Preparation of ZrO2-mullite nano-composite ceramics[J]. Journal of Central South University: Science and Technology, 2005, 36(5): 790–794.(in Chinese)

TORAYA H, YOSHIMURA M, SOMIYA S. Calibration curve for quantitative analysis of the monoclinic-tertragonal ZrO2 system by X-ray diffraction [J]. J Am Ceram Soc, 1984, 6(2): 112–119

PONTON C B, RAWLINGS R D. Mechanical properties of siliceramic glass-ceramics[J]. Mater Sci Tech, 1989, 5(9): 865–872.

CAMPOS A.L, SILVA N T, MELO F C L, et al. Crystallization kinetics of orthorhombic mullite from diphasic gels[J]. Journal of Non-crystalline Solids, 2002, 304(1/3): 19–24.

TKALCEC E, KURAJICA S, IVANKOVIC H. Diphasic aluminosilicate gels with two stage mullization in temperature range of 1 200–1 300 °C[J]. J Eur Ceram Soc, 2005, 25(5): 613–626.

MCPHERSON R. Preparation of mullite-zirconia composites from glass powder[J]. J Am Ceram Soc, 1986, 69(3): 297–298.

JIN Xi-hai, GAO Lian, GUO Jing-kun. The structural change of diphasic mullite gel studied by XRD and IR spectrum analysis[J]. J Euro Ceram Soc, 2002, 22(8): 1307–1311.

POPA M, CALDERÓN-MORENO J M, POPESCU L, et al. Crystallization of gel-derived and quenched glasses in the ternary oxide Al2O3-ZrO2-SiO2 system[J]. Journal of Non-crystalline Solids, 2002, 297(2/3): 290–300.

DONG X, WILLIAM J T. Mullite formation kinetics of a single-phase gel[J]. J Am Ceram Soc, 1990, 73(4): 964–969.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2003AA332040) supported by the National High Technology Research and Development Program of China

Rights and permissions

About this article

Cite this article

Liang, Sq., Tan, Xp., Li, Sq. et al. Structure and mechanical properties of ZrO2-mullite nano-ceramics in SiO2-Al2O3-ZrO2 system. J Cent. South Univ. Technol. 14, 1–6 (2007). https://doi.org/10.1007/s11771-007-0001-8

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-007-0001-8