Abstract

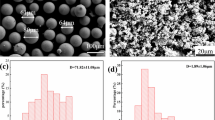

Ni-based alloy coating on 21-4-N heat-resistant steel was prepared using CO2 laser, and the high-temperature abrasion wear was tested. The microstructure of this cladding layer and its abrasion wear behavior at high temperature by changing compositions and temperatures were investigated by means of optical microscope and scanning electron microscope. Among the three compositions of cladding layer, i. e. Ni21+20%WC+0.5%CeO2, Ni25+20%WC+0.5%CeO2 and Ni60+20%WC+0.5%CeO2, the experimental results show that Ni21+20%WC+0.5%CeO2 cladding layer is made up of finer grains, and presents the best abrasion wear behavior at high temperature. The wear pattern of laser cladding layer is mainly grain abrasion at lower temperature, and it would be changed to adhesive abrasion and oxide abrasion at higher temperature.

Similar content being viewed by others

References

SHANG Li-juan, ZHU Jin-ping, TAN Chun-xi. Study on laser cladding layer of Ni-base and Co-base alloys[J]. China laser, 1990, 17(8): 491–494. (in Chinese)

Folkes J. Surface modification and coating with lasers[J]. Materials Science Forum, 1997, 46(2): 261–278.

Dubrujeaud B, Fontes A. Surface modification technology [R]. London: The Institute of Materials, 1997.

GAO Yang, PAN Feng, LIANG Yong, et al. Structure and oxidation properties of thermal barrier coatings by laser cladding on superalloy substrates[J]. Materials Science & Engineering, 2003, 21(1): 4–7. (in Chinese)

LUAN Jing-fei. A study on the wear resistance of laser cladding layers on grey iron[J]. Tribology, 2002, 22(2): 103–106. (in Chinese)

Tomlinson W J, Cash M. Dry sliding wear of grey iron laser surface clad with 14% – 40% chromium [J]. Wear, 1991, 42(1): 383–386.

GAO Yang, TONG Bai-yun, LIANG Yong. Investigation on structure and properties of laser remelting Ni-base alloy coatings[J]. Chinese Journal of Materials Research, 2003, 17(1): 87–91. (in Chinese)

Babu S S, Martukanitz R P, David A S. Toward prediction of microstructural evolution during laser surface alloying[J]. Metallurgical and Materials Transactions A, 2002, 33(1): 1189–1195.

JIANG Xiang-ping. Structure and Application of Vehicles and Diesel Engines[M]. Beijing: Mechanical Industry Press, 1982. (in Chinese)

ZHENG Shi-an, WANG Shun-xing, DONG Qi-ming, et al. Study on high-temperature dry slide wear of laser cladding Ni-base alloy[J]. China Surface Technology, 1999, 12(1): 25–29. (in Chinese)

LI Chun-hua, XU Kai-di, WANG Shun-xing, et al. Influence on the exhaust valve quality of laser cladding treatment[J]. Heat Treatment of Metals, 2000, 25(7): 8–9. (in Chinese)

ZHANG Da-wei, LEI Tie-cui, ZHANG Jing-guo, et al. The effects of heat treatment on microstructure and erosion properties of laser surface clad Ni-base alloy[J]. Surface and Coatings Technology, 1999, 11(5): 176–183. (in Chinese)

WANG Shun-xing, TIAN Bao-hong, LI Quan-an, et al. Investigate on applications of laser cladding technology on the exhaust valve and modling tool[J]. China Surface Technology, 2000, 13(4):41–43. (in Chinese)

XU Chun-jiang, ZHOU Li-bo. Alloy Steel and Hightemperature Alloy [M]. Beijing: Beijing University of Aeronautics and Astronautic Press, 1993. (in Chinese)

LIU Su-qin, ZHENG Shi-an, WANG Shun-xing. Microstructure and tribology behaviors of laser cladding layer of self-melted Ni-base alloys[J]. Journal of Luoyang Institute of Technology, 1998, 19 (1): 6–11. (in Chinese)

DUAN Gang, WANG Hua-ming. High-temperature wear resistance a laser clad γ/Cr3Si metal silicone composite coating [J]. Scripta Materialia, 2002, 46(1): 107–111.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Liu, Sq. & Wang, Sx. Microstructure and abrasion wear behavior of Ni-based laser cladding alloy layer at high temperature. J Cent. South Univ. Technol. 12, 403–405 (2005). https://doi.org/10.1007/s11771-005-0171-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0171-1