Abstract

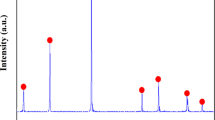

This study aims to assess the impact of TiC content on the sintering behavior, microstructure, and mechanical properties of Ti3O-Fe2TiO4 composites produced by the reactive spark plasma sintering (SPS) technique. The powders of Ti3O, Ti, Fe, and TiC were utilized as the starting materials, sintered by SPS under 1500 °C at 45 MPa for 7 min. The high relative density of 97.16% was achieved for the maximum TiC content (namely 30 vol.%). X-ray diffraction patterns and microstructural observations endorsed the in situ formation of Fe2TiO4 compound during the SPS process. Because this phase has a low melting point, its presence could activate the liquid phase sintering mechanism, promoting the sintering behavior of the as-sintered composites. In addition, when more TiC content was added to the composite matrix, the fracture mode changed from intergranular to mixed-mode. In terms of mechanical properties, the highest macro-hardness (13.29 GPa), micro-hardness (1244.84 HV0.3 kg), and bending strength (601 MPa) were achieved by the composite containing the highest proportion of TiC within the tested range.

Similar content being viewed by others

References

S.L. Tang, Y.F. Li, Y.R. Wang, Y.M. Gao, Q.L. Zheng, and D.W. Yi, Theoretical Study of Mechanical and Thermodynamic Properties of Titanium Oxides TixOy, Mater. Chem. Phys., 2018, 213, p 538–547. https://doi.org/10.1016/j.matchemphys.2018.01.038

A. Jostsons and A.S. Malin, The Ordered Structure of Ti3O, Acta Crystallogr. B Struct. Sci. Cryst., 1968, 24, p 211–213. https://doi.org/10.1107/s0567740868001974

M. Czakler and U. Schubert, Carboxylate-Substituted Ti(IV) Oxo Clusters with a Ti3O Core, Inorg. Chim. Acta., 2018, 471, p 567–569. https://doi.org/10.1016/j.ica.2017.11.055

S.A. Delbari, M.S. Shakeri, I. Salahshoori, M. Shahedi Asl, A. Sabahi Namini, A. Abdolmaleki, M. Sheikhlou, M. Farvizi, H.W. Jang, and M. Shokouhimehr, Characterization of TiC Ceramics with SiC and/or WC Additives Using Electron Microscopy and Electron Probe Micro-Analysis, J. Taiwan Inst. Chem. Eng., 2021, 123, p 245–253. https://doi.org/10.1016/j.jtice.2021.05.039

H. Yu, A. Sabahi Namini, S.A. Delbari, Q. Van Le, D. Kim, J.H. Cha, S.-H. Lee, S.Y. Kim, H.W. Jang, and M. Shokouhimehr, Microstructure of Spark Plasma Sintered TiC–TiB2–SiCw Composite, Mater. Chem. Phys., 2022, 281, p 125877. https://doi.org/10.1016/j.matchemphys.2022.125877

S.A. Delbari, J. Lee, M. Sheikhlou, A.S. Namini, S. Jung, J.H. Cha, S.-H. Lee, R.S. Varma, H.W. Jang, and M. Shokouhimehr, Effect of Iron Nanoparticles on Spark Plasma Sinterability of ZrB2-Based Ceramics, J. Aust. Ceram. Soc., 2022, 58, p 1117–1128. https://doi.org/10.1007/s41779-022-00777-4

S.A. Delbari, A.S. Namini, S. Lee, S. Jung, J. Wang, S.-H. Lee, J.H. Cha, J.H. Cho, H.W. Jang, S.Y. Kim, and M. Shokouhimehr, Microstructural and Nanoindentation Study of TaN Incorporated ZrB2 and ZrB2–SiC Ceramics, Sci. Rep., 2022, 12, p 13765. https://doi.org/10.1038/s41598-022-17797-6

H. Yu, M.S. Shakeri, A. Sabahi Namini, S.A. Delbari, Q. Van Le, J. Lee, S.Y. Kim, S.-H. Lee, H.W. Jang, Z. Swiatkowska-Warkocka, and M. Shokouhimehr, HRTEM and XPS Characterizations for Probable Formation of TiBxNy Solid Solution during Sintering Process of TiB2–20SiC–5Si3N4 Composite, Mater. Chem. Phys., 2022, 288, p 126380. https://doi.org/10.1016/j.matchemphys.2022.126380.(2022)

A.B. Peters, D. Zhang, D.C. Nagle, and J.B. Spicer, Reactive Two-Step Additive Manufacturing of Ultra-High Temperature Carbide Ceramics, Addit. Manuf., 2023, 61, p 103318. https://doi.org/10.1016/j.addma.2022.103318

B.R. Golla, A. Mukhopadhyay, B. Basu, and S.K. Thimmappa, Review on Ultra-High Temperature Boride Ceramics, Prog. Mater. Sci., 2020, 111, p 100651. https://doi.org/10.1016/j.pmatsci.2020.100651

D. Ni, Y. Cheng, J. Zhang, J.-X. Liu, J. Zou, B. Chen, H. Wu, H. Li, S. Dong, J. Han, X. Zhang, Q. Fu, and G.-J. Zhang, Advances in Ultra-High Temperature Ceramics, Composites, and Coatings, J. Adv. Ceram., 2022, 11, p 1–56. https://doi.org/10.1007/s40145-021-0550-6

M. Shokouhimehr, S.A. Delbari, A.S. Namini, E. Taghizadeh, S. Jung, J.H. Cho, Q. Van Le, J.H. Cha, S.Y. Kim, and H.W. Jang, Nanostructure and Nanoindentation Study of Pulse Electric-Current Sintered TiB2–SiC–Cf Composite, Sci. Rep., 2023, 13, p 379. https://doi.org/10.1038/s41598-022-27186-8

A. Lynam, A.R. Romero, F. Xu, R.W. Wellman, and T. Hussain, Thermal Spraying of Ultra-High Temperature Ceramics: A Review on Processing Routes and Performance, J. Therm. Spray Technol., 2022, 31, p 745–779. https://doi.org/10.1007/s11666-022-01381-5

W.G. Fahrenholtz and G.E. Hilmas, Ultra-High Temperature Ceramics: Materials for Extreme Environments, Scr. Mater., 2017, 129, p 94–99. https://doi.org/10.1016/j.scriptamat.2016.10.018

K. Cui, H. Mao, Y. Zhang, J. Wang, H. Wang, T. Tan, and T. Fu, Microstructure, Mechanical Properties, and Reinforcement Mechanism of Carbide Toughened ZrC-Based Ultra-High Temperature Ceramics: A Review, Compos. Interfaces, 2022, 29, p 729–748. https://doi.org/10.1080/09276440.2021.2012409

E. Castle, T. Csanádi, S. Grasso, J. Dusza, and M. Reece, Processing and Properties of High-Entropy Ultra-High Temperature Carbides, Sci. Rep., 2018, 8, p 8609. https://doi.org/10.1038/s41598-018-26827-1

A.B. Peters, C. Wang, D. Zhang, A. Hernandez, D.C. Nagle, T. Mueller, and J.B. Spicer, Reactive Laser Synthesis of Ultra-High-Temperature Ceramics HfC, ZrC, TiC, HfN, ZrN, and TiN for Additive Manufacturing, Ceram. Int., 2023, 49, p 11204–11229. https://doi.org/10.1016/j.ceramint.2022.11.319

H. Zhang, D. Hedman, P. Feng, G. Han, and F. Akhtar, A High-Entropy B4 (HfMo2TaTi)C and SiC Ceramic Composite, Dalton Trans., 2019, 48, p 5161–5167. https://doi.org/10.1039/C8DT04555K

F. Barragh Jam, H. Bangi Houri, and M. Ferdosi, Characterization of TiB2 Reinforced Aluminum Matrix Composite Synthesized by In Situ Stir Casting Method, J. Compos. Compd., 2020, 2, p 163–170. https://doi.org/10.29252/jcc.2.4.1

A. Sabahi Namini, S.A. Delbari, N. Baydogan, M. Vajdi, F. Sadegh Moghanlou, and M. Shahedi Asl, Spark Plasma Sinterability of TiC Ceramics with Different Nitride Additives, J. Taiwan Inst. Chem. Eng., 2021, 123, p 363–370. https://doi.org/10.1016/j.jtice.2021.05.004

Y. Zhang, J. Nie, and J. Luo, Effects of Phase and Doping on Flash Sintering of TiO2, J. Ceram. Soc. Japan, 2016, 124, p 296–300. https://doi.org/10.2109/jcersj2.124.P4-1

B. Debalina, N. Vaishakh, M. Jagannatham, K. Vasanthakumar, N.S. Karthiselva, R. Vinu, P. Haridoss, and S.R. Bakshi, Effect of Different Nano-Carbon Reinforcements on Microstructure and Properties of TiO2 Composites Prepared by Spark Plasma Sintering, Ceram. Int., 2016, 42, p 14266–14277. https://doi.org/10.1016/j.ceramint.2016.06.057

S. Mohapatra, D.K. Mishra, G. Mishra, G.S. Roy, D. Behera, S. Mantry, and S.K. Singh, A Study on Sintered TiO2 and TiO2/SiC Composites Synthesized through Chemical Reaction Based Solution Method, J. Compos. Mater., 2013, 47, p 3081–3089. https://doi.org/10.1177/0021998312462430

D.S. Ginley and R.J. Baughman, Preparation and Czochralski Crystal Growth of the Iron Titanates, FeTiO3, Fe2TiO4, and Fe2TiO5, Mater. Res. Bull., 1976, 11, p 1539–1543. https://doi.org/10.1016/0025-5408(76)90106-9

V. Nguyen, M.S. Asl, S.A. Delbari, Q. Van Le, A.S. Namini, J.H. Cha, S. Lee, H.W. Jang, M. Mustapha, M. Mohammadi, and M. Shokouhimehr, Microstructural Evolution during Spark Plasma Sintering of TiC–AlN–Graphene Ceramics, Int. J. Refract. Hard Met., 2021, 96, p 105496. https://doi.org/10.1016/j.ijrmhm.2021.105496

D.J. Fourie, J.J. Eksteen, and J.H. Zietsman, Calculation of FeO-TiO2-Ti2O3 Liquidus Isotherms Pertaining to High Titania Slags, J. South Afr. Inst. Min. Metall., 2005, 105, p 695–710.

D. Sciti, L. Zoli, A. Vinci, L. Silvestroni, S. Mungiguerra, and P. Galizia, Effect of PAN-Based and Pitch-Based Carbon Fibres on Microstructure and Properties of Continuous Cf/ZrB2-SiC UHTCMCs, J. Eur. Ceram. Soc., 2020 https://doi.org/10.1016/j.jeurceramsoc.2020.05.032

J. Zou, G.J. Zhang, and Y.M. Kan, Formation of Tough Interlocking Microstructure in ZrB2-SiC-Based Ultrahigh-Temperature Ceramics by Pressureless Sintering, J. Mater. Res., 2009, 24, p 2428–2434. https://doi.org/10.1557/jmr.2009.0274

R. Stadelmann, ZrB2-SiC Based Ultra High Temperature Ceramic Composites: Mechanical Performance and Measurement and Design of Thermal Residual Stresses for Hypersonic Vehicle Applications, 2015, 270.

R. Licheri, R. Orrù, C. Musa, and G. Cao, Combination of SHS and SPS Techniques for Fabrication of Fully Dense ZrB2-ZrC-SiC Composites, Mater. Lett., 2008, 62, p 432–435. https://doi.org/10.1016/j.matlet.2007.05.066

D.D. Jayaseelan, Y. Wang, G.E. Hilmas, W. Fahrenholtz, P. Brown, and W.E. Lee, TEM Investigation of Hot Pressed -10 vol.%SiC-ZrB2 Composite, Adv. Appl. Ceram., 2011, 110, p 1–7. https://doi.org/10.1179/174367510X12722693956310

J.L. Cao, Q. Xu, S.Z. Zhu, J.F. Zhao, and F.C. Wang, Microstructure of ZrB2–SiC Composite Fabricated by Spark Plasma Sintering, Key Eng. Mater., 2008, 368–372, p 1743–1745. https://doi.org/10.4028/www.scientific.net/kem.368-372.1743

T. Csanádi, A. Naughton-duszová, and J. Dusza, Scripta Materialia Anisotropic Slip Activation via Homogeneous Dislocation Nucleation in ZrB2 Ceramic Grains during Nanoindentation, Scr. Mater., 2018, 152, p 89–93. https://doi.org/10.1016/j.scriptamat.2018.04.025

M. Fattahi, Y. Pazhouhanfar, S.A. Delbari, S. Shaddel, A. Sabahi Namini, and M. Shahedi Asl, Strengthening of Novel TiC–AlN Ceramic with In-Situ Synthesized Ti3Al Intermetallic Compound, Ceram. Int., 2020 https://doi.org/10.1016/j.ceramint.2020.02.213

Y. Watanabe, M. Hattori, T. Chiba, and H. Sato, Microstructural Stability of Ti based Composites Fabricated by Spark Plasma Sintering, MATEC Web Conf., 2020, 321, p 03023. https://doi.org/10.1051/matecconf/202032103023

A.S. Rogachev, S.G. Vadchenko, N.A. Kochetov, DYu. Kovalev, I.D. Kovalev, A.S. Shchukin, A.N. Gryadunov, F. Baras, and O. Politano, Combustion Synthesis of TiC-Based Ceramic-Metal Composites with High Entropy Alloy Binder, J. Eur. Ceram. Soc., 2020, 40, p 2527–2532. https://doi.org/10.1016/j.jeurceramsoc.2019.11.059

Acknowledgment

This work was supported by The Natural Science Foundation of The Jiangsu Higher Education Institutions of China (Grant No. 21KJB430045), the Entrepreneurship and Innovation Plan of Jiangsu Province (Grant No. JSSCBS20221303), The Zhenjiang Key Research and Development Program of China (Grant No. GY2023025) The Young Teachers’ Enterprise Practice Program in Vocational Colleges of Jiangsu Province (Grant No.2023QYSJ128).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, T., Fan, K., Xu, Y. et al. Microstructure, Mechanical Properties, and Sintering Behavior of Ti3O-Fe2TiO4-TiC Composites. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09411-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09411-9