Abstract

Within cold-forming processes, the influence of forming induced residual stresses is a critical issue regarding the life-time behaviour of the formed components. However, a targeted use of forming-induced residual stresses is also capable to improve the components properties. The rotation-symmetrical full-forward extrusion is used as a reference process to investigate the generation of residual stresses within manufacturing. A novel and generally applicable computational evaluation procedure is introduced, which achieves to compute and visualize the evolution of the residual stress state during the entire forming operation. Simulative results are compared with their experimental counterparts. The near-surface residual stresses in the formed component are evaluated in axial and tangential direction by X-ray diffraction. Indentation tests are used to determine the micro-hardness inside the components and optical instruments quantify geometrical differences.

Similar content being viewed by others

References

Macherauch E, Hauk V (1987) Residual Stresses in Science and Technology. vol 1 and 2. DGM-Informationsgesellschaft, Oberursel

Denks IA (2008) Entwicklung einer Methodik zur Erfassung randschichtnaher Eigenspannungsverteilungen σ(z) in polykristallinen Werkstoffen mittels energiedispersiver Diffraktion. Dissertation, Universität Kassel, University Press, Kassel

Billigmann J, Feldmann H (1973) Stauchen und Pressen–Handbuch für das Kalt- und warm-massivumformen von stählen und nichteisenmetallen. Carl Hanser Verlag, München

Macherauch E, Wohlfarth H, Wolfstieg U (1973) Zur zweckmäßigen Definition von Eigenspannungen. Härterei Tech Mitteilungen 28:201–211

Niku-Lari A (1987) Advances in surface treatments: technology—applications—effects. In: Residual stresses, vol 4. Pergamon Press, Oxford

Tekkaya AE, Gerhardt J, Burgdorf M (1985) Residual stresses in cold-formed workpieces. Ann CIRP 34(1):225–230

Steinmann P (2015) Geometrical Foundations of Continuum Mechanics. Springer, Berlin Heidelberg

Tekkaya AE (1986) Ermittlung von Eigenspannungen in der Kaltmassivumformung. Dissertation, Band 83 von IFU - Berichte aus dem Institut für Umformtechnik der Universität Stuttgart. Springer, Berlin, Heidelberg

Wang Z, Gong B (2002) Residual stress in the forming of materials, handbook of residual stress and deformation of steel. In: Totten G (ed) Handbook of residual stress and deformation. Materials Park, Ohio

Tekkaya AE (2000) State-of-the-art of simulation of sheet metal forming. J Mat Prod Tech 103:14–22

Lacarac V, Chang CC, Bramley AN, Tierney MJ, McMahon CA, Smith DJ (2004) Predictions and measurements of residual stresses from forging and heat treatment. Proc Inst Mech Eng Part B J Eng Manuf 218(3):301–313

Tekkaya AE (2005) A guide for validation of FE simulations in bulk metal forming. Arab J Sc Engrg 30-1C:113–136

ICFG-Document 4/82 (1983) General aspects of tool design and tool materials for cold and warm forging. Portcullis Press Ltd., Redhill

ICFG-Document 5/82 (1983) Calculation methods for cold forging tools. Portcullis Press Ltd., Redhill

ICFG-Document 6/82 (1983) General recommendations for design, manufacture and operational aspects of cold extrusion tools for steel. Portcullis Press Ltd., Redhill

DIN EN 10263-5:2002-02 (2001) Steel rod, bars and wire for cold heading and cold extrusion—part 5: technical delivery conditions for stainless steels. German Version EN 10263(5): 2001

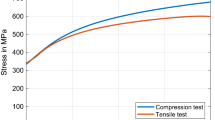

DIN 50106:2016-11. Testing of metallic materials—compression test at room temperature

Hockett J, Sherby O (1975) Large strain deformation of polycrystalline metals at low homologous temperatures. Int J Mech Phys Sol 23(2):87–98

Steenberg T, Christensen E, Bjerrum NJ, Bay N, Wibom O (2000) Cold forging of stainless steel with FeCl3 based lubricants. Lubr Eng 56(6):26–30

Ruud C (2002) Measurement of Residual stress. In: Totten G (ed) Handbook of residual stress and deformation. Materials Park, Ohio

Bragg WH (1913) The reflection of X-rays by crystals. Proc R Soc 88(605):428–438

Fitzpatrick ME, Fry AT, Holdway P, Kandil FA, Shackleton J, Suominen L (2005) Determination of residual stresses by X-ray diffraction—issue 2. Measurement Good Practice Guide No. 52. National Physical Laboratory, Teddington

Eigenmann B, Macherauch E (1995) Röntgenographische Untersuchungen von Spannungszuständen in Werkstoffen, Teil I. Mat Wiss Werkstofftechn 26:148–160

DIN EN 15305_2009-01. Non-destructive testing—test method for residual stress analysis by X-ray diffraction. German version EN 15305:2008

Jenkins R (1995) Quantitative X-ray spectometry, Second edn. Dekker, New York

Eigenmann B, Macherauch E (1995) Röntgenographische Untersuchungen von Spannungszuständen in Werkstoffen, Teil II. Mat Wiss Werkstofftechn 26:199–216

Eigenmann B, Macherauch E (1995) Röntgenographische Untersuchungen von Spannungszuständen in Werkstoffen, Teil III. Mat Wiss Werkstofftechn 27:426–437

Hinkfoth R (2003) Bulk forming processes. Verlagshaus Mainz GmbH, Aachen

DIN EN ISO 14577:2015-11 (2015) Metallic materials—instrumented indentation test for hardness and materials parameters—part 1: test method German Version EN ISO 14577(1):2015

Acknowledgements

Our research activities are funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) within the scope of the priority program SPP2013 - Targeted Use of Forming Induced Residual Stresses in Metal Components in the subproject P10 (project number: 374688875).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Landkammer, P., Jobst, A., Kiener, C. et al. Investigations on residual stress generation in full-forward-extrusion. Prod. Eng. Res. Devel. 13, 169–180 (2019). https://doi.org/10.1007/s11740-019-00892-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-019-00892-5