Abstract

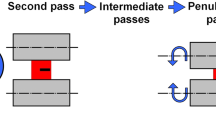

Incremental bulk forming technologies are investigated with respect to the creation of ultrafine-grained aluminium material. Based on first investigations of spin extrusion the technology of gradation rolling for rod shaped billets was developed. High strain generation as precondition for grain refinement is caused by the so called knead effect during processing in incremental rolling. Cross sections of processed billets show a demarcated area of different reflexion behaviour and a corresponding increase in hardness. In this area a gradient with decreasing grain size in surface direction is shown by crystallographic mapping. A several millimetre thick layer of refined material has been obtained.

Similar content being viewed by others

References

Azushima A, Kopp R, Korhonen A et al (2008) Severe plastic deformation (SPD) processes for metals. CIRP Ann—Manuf Technol 57:716–735

Zhu YT, Butt DP (2004) Nanomaterials by severe plastic deformation. Encyclopedia of nanotechnology, volume 6. American Scientific Publishers, Stevenson Ranch, CA, pp 843–856

Rosochowski A (2005) Processing metals by severe plastic deformation. Solid State Phenom 101–102:13–22

Beygelzimer Y, Orlov D, Varyukhin V (2002) A new severe plastic deformation method: twist extrusion. In: Zhu YT, Langdon TG, Mishra RS, Semiatin SL, Lowe TC (eds) Ultrafine grained metals II. TMS, pp 297–304

Hockauf M et al (2006) Mechanical properties and microstructural changes of ultrafine-grained AA6063T6 during high-cycle fatigue. Int J Mat Res 97:10

Meyer LW, Sommer K, Halle T, Hockauf M (2008) Crack growth in ultrafine-grained AA6063 produced by equal-channel angular pressing. J Mater Sci 43:7426–7431

Wielage B, Nickel D, Lampke T et al (2008) Corrosion characteristics of an ultrafine-grained Al-Mg-Si alloy (AA6082). Materials science forum. Nanomater Sev Plast Deform IV 584-586:988–993

Saito Y, Tsuji N, Utsunomiya H, Sakai T, Hong RG (1998) Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scripta Mater 39:1221–1227

Müller C, Bohn T, Bruder E et al (2007) Severe plastic deformation by linear flow splitting. Materwiss Werksttech 38:842–854

Lu K, Shaw L, Zehetbauer MJ, Zhu YT (ed.) (2009) Bulk materials with a nanostructured surface and coarse-grained interior. Bulk nanostructured materials, Wiley-VCH Verlag GmbH and Co. KGaA: 649–671

Bergmann M, Brůžek B, Lang H (2010) Properties of microstructurally optimized materials with graded grain size on the example of bolts. Materials and Design 31(3):1438–1443

Awiszus B, Meyer F, Meyer LW, Hahn F (2005) Erweiterung der formgebungsgrenzen durch inkrementelle zyklische Umformung am Beispiel des Drückwalzens (Abstreckdrücken). Tagungsband zum Abschlusskolloquium des DFG Schwerpunktprogramms 1074 Erweiterung der Formgebungsgrenzen bei Umformprozessen, 3. Mai 2005, Aachen

Hahn F (2003) Untersuchung des zyklischen plastischen Werkstoffverhaltens unter umformnahen Bedingungen. Dissertation TU Chemnitz

Neugebauer R, Glass R, Hoffmann M (2005) Spin extrusion—a new partial forming technology based on 7 nc-axes machining. CIRP Ann—Manuf Technol 54:241–244

Neugebauer R, Putz M, Bergmann M (2009) Lokale Hochverformung zur Erzeugung von ultrafeinkörnigen Zonen. Materwiss Werksttech 40:512–516

Acknowledgments

The authors acknowledge the DFG for supporting this work carried out within the framework of project SFB 692.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neugebauer, R., Sterzing, A. & Bergmann, M. Severe plastic deformation by incremental bulk metal forming. Prod. Eng. Res. Devel. 4, 391–397 (2010). https://doi.org/10.1007/s11740-010-0236-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0236-3