Abstract

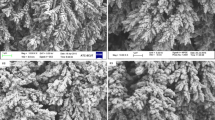

Surface modification is a direct and effective way to enhance the efficiency of heat exchangers. Surface modification by forming a microporous coated layer can greatly enhance the boiling heat transfer and thus achieve a high performance. In this paper, we systematically investigate the boiling behavior on a plain surface with/without sintered microporous coatings of copper powder. The results demonstrated that the sintered surface has a better performance in nucleate boiling due to the increased nucleation sites. The superheat degree is lower and the bubble departure diameter is larger for the sintered surface than for the plain surface, so the heat can be carried away more efficiently on the sintered surface. In addition, the heat transfer capacity on the sintered surface depends on both the powder size and the coating thickness for a high flux tube. The optimum heat transfer capacity can be obtained when the thickness of the microporous coating layer is 3–5 times of the sintered powder diameter. As a result, the heat transfer coefficient tube can be up to 3 times higher for the tube with a sintered surface than that with a plain surface, showing a pronounced enhancement in heat transfer and a high potential in chemical engineering industry application.

Similar content being viewed by others

References

Wang L, Khan A R, Erkan N, Gong H, Okamoto K. Critical heat flux enhancement on a downward face using porous honeycomb plate in saturated flow boiling. International Journal of Heat and Mass Transfer, 2017, 109: 454–461

Holguin R, Kota K, Wootton S, Chen R, Ross S. Enhanced boiling heat transfer on binary surfaces. International Journal of Heat and Mass Transfer, 2017, 114: 1105–1113

Deng D, Feng J, Huang Q, Tang Y, Lian Y. Pool boiling heat transfer of porous structures with reentrant cavities. International Journal of Heat and Mass Transfer, 2016, 99: 556–568

Mori S, Maruoka N, Okuyama K. Critical heat flux enhancement by a two-layer structured honeycomb porous plate in a saturated pool boiling of water. International Journal of Heat and Mass Transfer, 2018, 118: 429–438

Kim D E, Yu D I, Jerng DW, Kim MH, Ahn H S. Review of boiling heat transfer enhancement on micro/nanostructured surfaces. Experimental Thermal and Fluid Science, 2015, 66: 173–196

Zhong D, Meng J, Li Z, Guo Z. Critical heat flux for downward-facing saturated pool boiling on pin fin surfaces. International Journal of Heat and Mass Transfer, 2015, 87: 201–211

Chen T. An experimental investigation of nucleate boiling heat transfer from an enhanced cylindrical surface. Applied Thermal Engineering, 2013, 59(1–2): 355–361

Sohag F A, Beck F R, Mohanta L, Cheung F B, Segall A E, Eden T J, Potter J K. Enhancement of downward-facing saturated boiling heat transfer by the cold spray technique. Nuclear Engineering and Technology, 2017, 49(1): 113–122

Li S, Furberg R, Toprak M S, Palm B, Muhammed M. Natureinspired boiling enhancement by novel nanostructured macroporous surfaces. Advanced Functional Materials, 2008, 18(15): 2215–2220

Yan C, Dai Y, Xu H, Hou F. Fe-Ni-P coated composite powder with electroless plating and its sintering process. Rare Metal Materials and Engineering, 2011, 40(2): 384–388

Sirotkina A, Fedorovich E, Sergeev V. Model of formation and roughness calculation of the porous layer on the heated surface during nanofluids boiling. Propulsion and Power Research, 2017, 6 (2): 101–106

Xu P, Li Q, Xuan Y. Enhanced boiling heat transfer on composite porous surface. International Journal of Heat and Mass Transfer, 2015, 80: 107–114

Aznam SM, Mori S, Ogoshi A, Okuyama K. CHF enhancement of a large heated surface by a honeycomb porous plate and a gridded metal structure in a saturated pool boiling of nanofluid. International Journal of Heat and Mass Transfer, 2017, 115(A): 969–980

Nirgude V V, Sahu S K. Enhancement of nucleate boiling heat transfer using structured surfaces. Chemical Engineering and Processing: Process Intensification, 2017, 122: 222–234

Sun Y, Chen G, Zhang S, Tang Y, Zeng J, Yuan W. Pool boiling performance and bubble dynamics on microgrooved surfaces with reentrant cavities. Applied Thermal Engineering, 2017, 115: 432–442

Deng D, Feng J, Huang Q, Tang Y, Lian Y. Pool boiling heat transfer of porous structures with reentrant cavities. International Journal of Heat and Mass Transfer, 2016, 99: 556–568

Surtaev A S, Pavlenko A N, Kuznetsov D V, Kalita V I. Heat transfer and crisis phenomena at pool boiling of liquid nitrogen on the surfaces with capillary-porous coatings. International Journal of Heat and Mass Transfer, 2017, 108(A): 146–155

Ling W, Zhou W, Yu W, Liu R, Hui K S. Thermal performance of loop heat pipes with smooth and rough porous copper fiber sintered sheets. Energy Conversion and Management, 2017, 153: 323–334

Fu Y, Wen J, Zhang C. An experimental investigation on heat transfer enhancement of sprayed wire-mesh heat exchangers. International Journal of Heat and Mass Transfer, 2017, 112: 699–708

Wanotayan T, Panpranot J, Qin J, Boonyongmaneerat Y. Microstructures and photocatalytic properties of ZnO films fabricated by Zn electrodeposition and heat treatment. Materials Science in Semiconductor Processing, 2018, 74: 232–237

Deng D, Wan W, Feng J, Huang Q, Xie Y. Comparative experimental study on pool boiling performance of porous coating and solid structures with reentrant channels. Applied Thermal Engineering, 2016, 107: 420–430

Gheitaghy A M, Saffari H, Ghasimi D, Ghasemi A. Effect of electrolyte temperature on porous electrodeposited copper for pool boiling enhancement. Applied Thermal Engineering, 2017, 113: 1097–1106

Jaikumar A, Kandlikar S G. Enhanced pool boiling heat transfer mechanisms for selectively sintered open microchannels. International Journal of Heat and Mass Transfer, 2015, 88: 652–661

Jun S, Kim J, Son D, Kim H Y, You S M. Enhancement of pool boiling heat transfer in water using sintered copper microporous coatings. Nuclear Engineering and Technology, 2016, 48(4): 932–940

Liu J L, Dai Y L, Xia X M, Xu H, Wang X S. Manufacture and application of high efficiency boiling tube for heat exchanger. Advanced Materials Research, 2011, 236–238: 1640–1644

Acknowledgements

This research work is supported by the National High Technology Research and Development Program of China (Granted No. 2006AA05Z206), China National Torch Program, Research Grant (No. 16DZ2260600) from Science and Technology Commission of Shanghai Municipality, and the Fundamental Research Funds for the Central Universities (Nos. 222201717012 and 222201718005) and SINO PEC et al.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, H., Dai, Y., Cao, H. et al. Tubes with coated and sintered porous surface for highly efficient heat exchangers. Front. Chem. Sci. Eng. 12, 367–375 (2018). https://doi.org/10.1007/s11705-018-1703-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-018-1703-1