Abstract

This study mainly aimed to optimize a sustainable and green process for extracting bioactive compounds from Foshou fruit by using an integrated technique based on ultrasonic-microwave assisted extraction (UMAE). Response surface methodology (RSM) based on a Box–Behnken design was applied to determine optimal conditions. The following optimized UMAE processing parameters were obtained: sonication time (96.13 s), microwave power (305.28 W), and solid/solvent ratio (1:37). Based on a total phenolic compound extraction yield of 9.21 mg gallic acid (GA) equ/g dry weight (DW), a 2,2-diphenyl-1-picrylhydrazyl (DPPH) scavenging activity with a half maximal inhibitory concentration (IC50) of 27.52 μg GA equ, and an antioxidant capacity detected by 2,2′-azino-bis-3-ethylbenzthiazoline-6-sulphonic acid (ABTS) assay of 8.79 mg trolox equ/g DW. The optimized UMAE extract was superior to those obtained using microwave-assisted extraction (MAE) or conventional solvent extraction (CSE) methods. Scanning electron microscopy (SEM) analysis showed that the three extraction methods affected the sample tissue microstructure. Among them, UMAE caused the most marked structural disruption. UPLC-PDA-Q-TOF-MS analysis identified 67 phenolic compounds in the optimized UMAE extract of the Foshou fruit extract. This study indicated that the integrated UMAE technique is a suitable and safe technique to enhance the qualitative and quantitative extraction of phenolic compounds from Foshou fruit. These phenolic compounds can be used as a functional food ingredient in industrial production.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Citron (Citrus medica L.) is one of the three ancestral Citrus species, together with mandarin orange (C. reticulata Blanco) and pummelo (C. maxima (Burm.) Merr.) [1]. Foshou fruit (C. medica L. var. sarcodactylis Swingle) is classified in Rutaceae family and broadly cultivated in Asian countries. It is usually consumed as a functional food and raw material for some traditional Chinese medicines used to treat chronic diseases because of its content of bioactive compounds, especially phenolic compounds [2].

Phenolic compounds are bioactive, aromatic, and secondary plant metabolites that are widespread in the plant kingdom, have great potential for applications that reduce the risks of several chronic diseases [3, 4], and are closely associated with the effective management of chronic diseases [5]. These compounds have become important because of their associated health benefits, including protection against oxidative stress damage and lifestyle diseases [6]. Luna-Guevara et al. [7] emphasized that phenolic compounds elicit effects against several lifestyle diseases, such as obesity, types of cancers, diabetes mellitus, hypertension, and atherosclerosis. The use of phenolic compounds as bioactive substances has prompted researchers to optimize the efficacy of eco-friendly extraction procedures for green extraction strategies to save time, energy, and total production costs [8]. Green extraction involves innovative extraction technologies with advantages of using safe extraction techniques and clean solvents that do not include toxic chemicals, thereby avoiding the use of organic solvents [6,7,8,9,10].

Phenolic compound extraction via green extraction methods requires the optimization of various extraction parameters, such as raw material amount, and volume of solvent needed [6]. Innovative efforts devoted to improving extraction methods and ensuring compliance with optimization strategies include new extraction processes and alternatives to classical solvents. Alternative extraction processes should be developed on the basis of the modification of current technologies and their protocols [11, 12]. In contrast to classical extraction techniques, ultrasonic-assisted extraction (UAE) has emerged as a promising green extraction technology that fulfills various criteria, including low cost, eco-friendliness, safety, speed, and ease of use [13]. As an important improvement of UAE, ultrasonic/microwave-assisted extraction (UMAE) is an integration of UAE with microwave-assisted extraction (MAE) via simultaneous irradiation [14].

Green extraction should be associated with the use of safe solvents, considering that the exacerbation of environmental pollution caused by the excessive use of volatile and dangerous organic solvents has motivated researchers to develop alternative green solvents. Green solvents are mainly utilized to reduce the use of toxic solvents with their associated negative environmental impacts [8,9,10,11,12,13,14,15,16]. In this sense, water is considered to be a safe, environmentally sustainable, and green solvent [17].

Green extraction operations should be linked to effective statistical methods to determine the efficiency of extraction techniques, such as response surface methodology (RSM), which includes several arithmetical and statistical methods that can be used to identify the correlations between independent variables and responses. As an experimental methodology, RSM is used to define the effects of independent variables by analyzing the influences of independent variables on responses and to generate a mathematical model [18, 19]. RSM has been used to optimize extraction procedures for various natural products. Moreover, the resultant models generated by RSM correspond well with actual experimental outcomes [20].

The quality of extracts should be determined by special techniques, such as liquid chromatography coupled with mass spectrometry (LC-MS); LC-MS plays an important role in the determination, characterization, and identification of phenolic compounds in food and the classification and authentication of natural extracts [21]. As well the time-of-flight (TOF) is one of high-resolution mass spectrometry (HRMS) instrumentation and is considered the most generally used analyzer for the LC analysis of phenolic compounds in food matrices [22].

This study focused on finding the optimal conditions for the extraction of total phenolic compounds (TPCs) from Foshou fruit through UMAE as one of the most promising extraction technologies to obtain a safe extract applicable to the food industry. Consequently, the goals of this study were to:

-

Investigate the effects of various process parameters on the efficiency of TPC extraction from Foshou fruit using the UMAE process in preliminary single-factor experiments;

-

Optimize the UMAE conditions using RSM;

-

Compare optimized UMAE extract with those obtained by MAE and CSE in terms of TPC yield, antioxidant activity determined by 2,2-diphenyl-1-picrylhydrazyl free radical-scavenging activity (DPPH•-SA) assay, and antioxidant capacity determined by 2,2′-azino-bis-3-ethylbenzthiazoline-6-sulphonic acid radical cation scavenging effect (ABTS•+-SE) assay;

-

Compare the effects of the three extraction technologies on the Foshou microstructure;

-

Identification the phenolic compounds in the optimized UMAE extract of Foshou fruit using the UPLC-PDA-Q-TOF-MS.

Materials and methods

Chemicals

Gallic acid (CAS:149-91-7) was purchased from Shanghai Yuanye Bio-Technology Co., Ltd. China. Folin phenol reagent (Catalog Number: 73104861), Sodium Carbonate (CAS:497-19-8), Potassium persulfate (CAS:7727-21-1), Methanol (CAS: 67-56-1) and Ethanol (CAS:64-17-5) were purchased from Sinopharm Chemical Reagent Co., Ltd. (SCR), China. DPPH (CAS:1898-66-4) and Trolox (CAS:53188-07-1) were purchased from Sigma–Aldrich (USA). ABTS (CAS:30931-67-0) was purchased from TCI Europe N.V. (Belgium). All other chemical substances and solvents used were of analytical grade and stored in ideal conditions according to the manufacturer’s specifications.

Fruit preparation

Foshou fruit (C. medica L. var. sarcodactylis) was provided by Zhejiang Golden Hand Biological Technology Co., Ltd. in Jinhua, Zhejiang Province, China in November 2016. The whole Foshou fruits (peels and pulps) were washed with distilled water and cut into small slices with a thickness about 1 mm. The slices were dried to constant weight at 55 °C in an air oven and then milled using an electric grinder to obtain a fine powder. The fine powder was passed through a 40-mesh sieve to obtain Foshou fruit powder, which was packaged in polyethylene bags under vacuum and stored at 4 °C until analysis.

Ultrasonic/microwave equipment

The integrated techno-extraction procedures were performed using a CW-2000 Ultrasonic/microwave Cooperative Extractor/Reactor (Shanxi, Xi’an, China) with an adjustable microwave power range of 10–800 W, a microwave frequency of 2,450 MHz, the ultrasonic power level at a constant 50 W, and an ultrasonic frequency of 40 kHz. The ultrasonic transducer was directly linked to a reactor flask with a volume of 250 mL. The reactor flask was linked to a reflux condenser. Extractions were performed under a constant ultrasonic power/frequency ratio of 50 W/40 kHz.

TPC extraction procedures

Ultrasonic/microwave-assisted extraction (UMAE)

To obtain the ultrasonic/microwave-assisted Foshou fruit extract (UMAE), 2 g of Foshou fruit powder was extracted with distilled water at solid/solvent ratios ranging from 1:20 to 1:45 (g/mL), microwave power ranged from 200 to 700 W, and sonication time from 30 to 180 s in a single-factor experiment. In the RSM experiment, 2 g of Foshou fruit powder was extracted with distilled water (solid/solvent ratios of 1:30, 1:35, and 1:40; g/mL) at microwave power levels of 200, 300 and 400 W, and sonication times of 60, 90 and 180 s. The extraction temperature was controlled using a discontinuous model that did not exceed 70 °C during the sonication time, while the ultrasonic-microwave extractor was operated discontinuously, operated in running-cooling-running stages. The running time did not exceed 60 s and the extract was cooled for 120 s between the two running stages. After the extraction process, the Foshou fruit extract was allowed to cool to room temperature. The obtained volume of extract was adjusted to 100 mL in a standard flask and centrifuged at 4,000 rpm for 20 min. The supernatant solution was filtered under vacuum through the No.1 Whatman filter paper in a Buchner funnel and stored at 4 °C until further use.

Microwave-assisted extraction (MAE)

To obtain microwave-assisted Foshou fruit extract (MAE), the CW-2000 Ultrasonic/microwave Cooperative Extractor/Reactor was used in the item of microwave mode (ultrasonic mode turned off). The extraction parameters were used according to Dahmoune et al. [23] with slight modification. Briefly, 2 g of Foshou fruit powder was extracted by 60 mL distilled water (solid/solvent ratio 1:30, g/mL) with a microwave power setting at 400 W and an extraction time of 120 s. The subsequent steps, including filtration and centrifugation, were performed as described above in UMAE.

Conventional solvent extraction (CSE)

With a slight modification, the conventional solvent extract (CSE) was prepared according to Spigno et al. [24]. In brief, 2 g of Foshou fruit powder was extracted with 100 mL of distilled water (solid/solvent ratio 1:50, g/mL). The mixture was incubated in a shaking water bath for 2 h at 60 °C with shaking speed at 110 rpm. The subsequent steps including filtration and centrifugation were performed as described in UMAE.

Experimental design

Single-factor experiments

The effects of various extraction parameters (sonication time, microwave power, and solid/solvent ratio) were studied using a single-factor experimental design to make a preliminary determination of the extraction parameter values to be used in the RSM experiment. The other parameters were maintained at constant values as shown in Table 1.

Orthogonal experiment design

To optimize the effects of sonication time (X1), microwave power (X2), and solid/solvent ratio (X3), RSM was coupled with a quadratic model based on the Box–Behnken design (BBD) using Design Expert 10.0.0 (Stat-Ease, Inc., USA) software to determine the optimal parameter values required for maximum TPC yield. The BBD output was 17 runs, including 5 replicates as a center point. The data were subjected to regression analysis to ensure that the obtained responses between the independent variables (X1, X2, and X3) were well fitted with the general second-order polynomial equation (quadratic model) in Eq. (1):

where β0 is the regression coefficient for the intercept (a constant value); k is the number of variables (3); βi,βii, and βij are the coefficients of the linear, quadratic, and interactive terms, respectively; and xi, xii, and xij represent the coded independent variables. The actual values of factor levels (zi) were converted to coded values (xi) in a range without dimensions (− 1 to + 1) using the following formula:

where Δzi indicates the difference between the actual value in the central point (zi0) and the actual value of the lowest or highest level of a variable, and βd is the main coded limit value in the model for each variable [25].

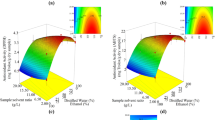

Analysis of variance (ANOVA) was used to evaluate the adequacy of the model by determining the lack of fit, F test value, p value Prob > F, and the coefficient of determination (R2). Based on the fitted polynomial equation, 3D surface plots were generated using regression coefficients to visualize the relationship between the values of each factor and the response, and to predict the optimal conditions. To validate the model, supplementary extraction trials were performed under the optimal conditions predicted by RSM and the results were compared with the predicted values generated by the regression model.

Analytical methods

Determination of TPC

The TPC contents of Foshou fruit extracts were determined using the Folin–Ciocalteu assay according to Chen et al. [26] with some modification. Briefly, 200 µL of Foshou fruit extract was added to 5 mL (0.2 N) of Folin phenol reagent. After 5 min, 4 mL of 7.5% sodium carbonate solution was added to the solution. The optical density of the mixture was measured at 765 nm using a UNICO UV-2100 spectrophotometer (UNICO SCIENTIFIC, HongKong) after incubation at room temperature in the dark for 105 min. The results were expressed as mg of gallic acid equivalents per gram dry weight (mg GA equ/g DW) according to the linear equation for gallic acid y = 0.0093x + 0.0214 at an R2 value of 0.99.

Determination of antioxidants activity

Determination of antioxidant activity by DPPH•-SA assay

The scavenging activity of Foshou fruit extract against DPPH• was determined according Rashed et al. [27] with a slight modification according DPPH• methanolic solution (3.5 mL, 60 µM) was added to 300 µL of Foshou fruit extract. After shaking, the reaction was carried out in the dark at room temperature. Absorbance was recorded at 517 nm after 40 min of incubation and converted to %DPPH•SA using the following equation:

where A0 is the absorbance of the control and A1 is the absorbance of the sample. Trolox solution (0.375 µg/mL) was used as a standard for comparing the results. The IC50 was expressed as µg GA equ.

Determination of antioxidant capacity by ABTS•+-SE assay

To evaluate the antioxidant capacity of Foshou fruit, ABTS•+SE assay according to the method of Rashed et al. [28] was used with slight modification. The ABTS stock solution was prepared by dissolving 38.41 mg of the ABTS in 10 mL of deionized water (7 mM). Potassium persulfate solution (2.45 mM) was prepared by dissolving 6.62 mg of potassium persulfate in 10 mL of deionized water. Then, 0.5 mL of the ABTS stock solution was mixed with 0.5 mL of potassium persulfate solution (1:1, v/v) to prepare the ABTS•+ solution. The ABTS•+ solution was kept for 12 h at room temperature in the dark to obtain a stable blue-green cation radical solution. The stable ABTS•+ solution was diluted with ethanol to an absorbance of 0.700 ± 0.020 at 734 nm before use. Then, 50 µL of Foshou fruit extract was added to 3.5 mL of the ABTS•+ solution and the mixture was allowed to react at room temperature in the dark. The absorbance at 734 nm was measured relative to a blank (distilled water instead of the extract) after reaction for 10 min. Trolox was used as a standard to plot a Trolox calibration curve at concentrations of 2.25, 4.50, 6.75, 9.00, 11.25, 13.5, and 16.5 µg/ml Trolox. Results were expressed as mg Trolox equivalents per g dry weight (mg Trolox equ/g DW) according to Zhang et al. [29] using the linear equation y = − 0.033x + 0.6531 and an R2 value of 0.99.

UPLC-PDA-Q-TOF-MS analysis

The UPLC-PDA-Q-TOF-MS analysis were done according to the method described by He et al. [30], with some modifications. The analysis were carried out on a WATERS ACQUITY UPLC device, a WATERS ACQUITY PDA detector (set at 200 and 600 nm.), and a WATERS UPLC BEH C18 column (1.7 µm, 2.1 mm, I.D., 100 mm) at 45 °C (temperature of column oven) (Waters Corp., Milford, USA). The injection volume of the sample was 1 µl. The mobile phase comprised of acetonitrile (A) and water with 0.1% formic acid (B) with a flow rate of 0.3 ml/min. Mass spectrometry executed on a WATERS MALDI SYNAPT Q-TOF MS device with electrospray ionization mass spectrometry (ESI-MS) (Waters Corp., Milford, USA).

The ESI-MS spectra were obtained in negative ion mode in the mass range of 20 to 1500 m/z. The voltage of capillary was 3.0 kV, while 20 V was the voltage of sample cone and collision energy was 6.0 eV. The desolvation gas temperature was 400 °C with 700 L/h flow, and the temperature of source block was 100 °C and the flow of cone gas was 50 L/h. All processes controlled and data analysis by MarkerLynx software (Waters, Milford, MA, USA). The widely accepted accuracy for confirmation of compositions was set at less than 10 ppm. The phenolic compounds were identified by comparing the molecular weight according to MS data which extracted by MarkerLynx software with the databases of the European Bioinformatics Institute and ChemSpider [31, 32].

Scanning electron microscopy (SEM) observation

Foshou fruit powder specimens (extracted and unextracted samples) were visually observed using a scanning electron microscope (SU 1510, Hitachi Corp., Tokyo, Japan) to investigate the effects of the different extraction methods on the Foshou fruit surface microstructure. After extraction, powder residues were dried in an oven at 50 °C until a constant weight was obtained before SEM analysis. The SEM observation were done at an accelerating beam voltage of 5.00 kV under high vacuum conditions, and a working distance of 9.5–9.8 mm.

Statistical analysis

Each extraction trial and all analyses were conducted in triplicate and all the data in this paper are reported as the mean ± SD. Microsoft Office Excel 2016 software was used to generate the linear equations and the IC50 values for the DPPH•SA assay. IBM SPSS Statistics software (Version 20.0. Armonk, NY: IBM Corp.) was used to determine the significance of differences between means at the 95% confidence level (P ≤ 0.05) using one-way analysis and Duncan’s test.

Results and discussions

Single-factor experiments

The results of single factor experiments are summarized in Table 1. The TPC yield from Foshou fruit extract was the highest (8.67 mg GA equ/g DW) at a sonication time of 90 s, constant microwave power of 500 W, and a solid/solvent ratio of 1:30 (g/mL). With the sonication time increased to 180 s, the yield decreased to 8.13 mg GA equ/g DW due to thermal degradation of the phenolic compounds. Based on these outcomes, we chose a sonication time of 90 s for the subsequent single-factor experiments, while sonication times of 60, 90, and 120 s were used for RSM experiments. The microwave power level had a significant effect on the TPC yield. With an increasing in microwave power from 200 W to 300 W, the TPC yield increased from 8.59 mg GA equ/g DW to 9.10 mg GA equ/g DW (the highest TPC yield), respectively. With higher microwave power levels of 400, 500, 600, and 700 W, the TPC yields decreased slightly to 8.76, 8.68, 8.61, and 8.48 mg GA equ/g DW, respectively. Statistically, there were no significant differences between the TPC yields at microwave power levels of 200, 500, 600, and 700 W, probably due to the degradation of phenolic compounds when using high levels of microwave power during the extraction process [33]. We chose a microwave power level of 300 W for use in subsequent single-factor experiments, while microwave power levels of 200, 300, and 400 W were used in RSM experiments. With increasingly wide solid/solvent ratios of 1:20, 1:25, 1:30, and 1:35, the TPC yields increased (8.19 8.72, 8.99, and 9.18 mg GA equ/g DW, respectively). A further widening of the solid/solvent ratio caused a decrease in the TPC yield. The highest TPC yield of 9.18 mg GA equ/g DW was obtained with a solid/solvent ratio of 1:35. Based on these results, we chose solid/solvent ratios of 1:30, 1:35, and 1:40 for the RSM experiments.

Modeling of UMAE

Optimization and prediction of extraction parameter values using RSM

To enhance the TPC yield, we used RSM based BBD to determine the optimal combination of the independent variables. The parameters included sonication time (X1), microwave power (X2), and solid/solvent ratio (X3) at a fixed sonication power/frequency ratio of 50 W/40 kHz. The coded and uncoded levels of the independent variables shown in Table 2. As well actual and predicted values of the dependent variables (response) are shown in Table 3. The actual values of TPC yield ranged from 8.56 to 9.20 mg GA equ/g DW, while the predicted values ranged from 8.57 to 9.18 mg GA equ/g DW. Based on multiple regression analysis, a final second-order polynomial equation in terms of coded factors with disregard the non-significant terms (P > 0.01) was created to obtain the maximum TPC yield from Foshou fruit (Eq. 4).

The optimal predicted extraction conditions to achieve the highest TPC yield (9.21 mg GA equ/g DW) were as follows: X1 = 96.1285 s, X2 = 305.278 W, and X3 = 1:37.The regression coefficients of the mathematical model describing the TPC yield as a function of A, B, and C are shown in Table 4. F test and p values were used to analyze the significance of each coefficient. Bezerra et al. [25] confirmed that a model will be well fitted to the experimental data if it shows a significant regression and a non-significant lack of fit. In this study, the model F value (163.44) was significant, and the p-value Prob > F was < 0.0001 (< 0.05). Furthermore, the lack of fit F-value of < 0.001 was not significant, and the p-value Prob > F was 0.51 (> 0.05). The value of R2 was (0.9953), indicating that the model satisfactorily described the real relationships between the chosen variables. The Adjusted R-squared (R2Adj) value in the model (0.9892) was close to R2. Moreover, the Predicted R-squared (R2pred) value (0.9648) was in reasonable agreement with R2adj. This confirms that the model was highly significant, where the difference was < 0.2. The regression coefficient from the experimental data and the adjusted data were reasonably close to 1, which indicated a high degree of correlation between the observed and predicted values.

The 3-D response surface plots of the interactions between the factors X1, X2, and X3 are shown in Fig. 1. All maximum points as critical points were found within the experimental region, indicating that they represented the optimal values. The overlap between X1 and X2 is shown in Fig. 1a. These two factors had a positive effect on the TPC yield with the same degree of proximity. X3 produced a curve that was broader than the X1 and X2 curves, indicating that it had the strongest effect.

Validation of the predictive model

We obtained the optimal values of the selected independent factors by solving the regression equation and analyzing the contour and response surface plots. To evaluate the validity of the model in Eq. (4), the extraction of TPC from of Foshou fruit was performed in triplicate under the optimal conditions, which included; X1 (96 s), X2 (305 W), and X3 (1:37). There was no significant difference between the experimental (9.21 mg GA equ/g DW) and predicted (9.22 mg GA equ/g DW) mean TPC yield values; hence, this model can be used to optimize TPC extraction from Foshou fruit.

Investigation of the UMAE, MAE, and CSE effects on the yield of TPC

Results of TPC that obtained with the optimized UMAE conditions were compared with those obtained using the MAE and CSE techniques. The highest TPC yield of 9.21 mg GA equ/g DW was obtained using UMAE, followed by the yields from MAE (9.09 mg GA equ/g DW) and CSE (8.72 mg GA equ/g DW), with significant differences between both UMAE and MAE, UMAE and CSE. Overall, the TPC yields obtained using water as a solvent were higher than those obtained by Liu et al. [34] and Jayaprakasha, Patil [35] who obtained TPC yields of 5.86 mg GA equ/g DW using 60% ethanol and 7.18 mg GA equ/g DW using 80% methanol, respectively.

Antioxidants activity

Antioxidant activity determination by DPPH•-SA assay

The IC50 values calculated based DPPH•-SA assay differed significantly between the UMAE, MAE, and CSE. UMAE reached the lower IC50 (27.52 µg GA equ) compared to the MAE (30.36 µg GA equ) and CSE (31.17 µg GA equ). Castillo et al. [36] studied the antioxidant activity of the C. medica and found that the IC50 (DPPH) was approximately 29.45 µg GA equ, which represented a lower antioxidant activity than was obtained with UMAE in this study, but higher than the activities we obtained with MAE and CSE.

Antioxidant capacity determination by ABTS•+-SE assay

The antioxidant capacity values of the UMAE, MAE, and CSE extracts determined in term of ABTS•+-SE assay were significantly different. The UMAE achieved the highest activity (8.79 mg Trolox equ/g DW), followed by MAE (8.39 mg Trolox equ/g DW), and CSE (8.17 mg Trolox equ/g DW). Sun et al. [37] determined the antioxidant capacities of the main citrus species and the results ranged from 104.64 to 269.40 mg/g Trolox equivalent. In another investigation, Menichini et al. [38] reported that the IC50 of C. medica L. cv Diamante (Rutaceae) peel extract in terms of ABTS•+-SE (%)was 3.48 mg/mL.

Double simultaneous irradiation (ultrasound/microwave) causes synergic effects on the extraction of bioactive compounds from plant matrices. Ultrasound dramatically increases the extraction efficiency through the cavity phenomenon that induces the release of soluble compounds from plant matrices by crashing cell walls.

At the same time, microwave quickly heats whole plant matrices, thereby causing the transmigration of dissolved molecules. Furthermore, the simultaneous irradiation enhances solvent permeation into the matrix and increases the solubility of compounds. Additionally, the power levels required by UMAE are lower than those of two single energy sources alone [11,12,13,14].

Our results showed that UMAE was considered the best technique. It allowed increasing the TPC yields by 5.62% and 1.32% compared with those of CSE and MAE, respectively. UMAE also improved the antioxidant activities by 11.71% and 2.60% compared with those of CSE and MAE, respectively. By contrast, UMAE increased the antioxidant capacities by 7.56% and 4.77% compared with those of CSE and MAE, respectively. UMAE shortened the extraction time by 98.66% and 19.89% compared with those of CSE and MAE, respectively.

UPLC-PDA-Q-TOF-MS analysis

According to the analysis of the optimized UMAE extract of Foshou fruit using the technique of chromatography, 67 phenolic compounds appeared in the extract (Table 5). The base peak intensity (BPI) chromatogram of optimized UMAE extract of Foshou fruit (negative ion mode) shown in Fig. 2.

Interestingly, the optimized UMAE extract of Foshou fruit contains many compounds that have important properties such as anti-cancer, anti-inflammatory, anti-diabetic, and antimicrobial, as an example 4′-hydroxychalcone is one of Chalcones, and has a potential effect on the prevention and treatment of the inflammatory and cancer [39]. The norathyriol found in Mango fruit and has an anti-cancer activity, where decreased the viability of MCF-7 breast cancer cells [40]. Tian et al. [41] confirmed that the bellidifolin compound significantly decreased in the fasting blood glucose sample, in addition to improving the oral glucose tolerance and decresing of the fasting serum insulin. In the study conducted by Qiu, Chen [42], ophioglonin showed slight anti-hepatitis B virus surface antigen activity at 25 µM. 2,2′,4′-trihydroxy-6′-methoxy-3′,5′-dimethylchalcone possessed an antiprotozoal activity against Leishmania donovani at IC50 7.5 µg/mL of methanolic extract of Psorothamnus polydenius [43]. Bauhinoxepins A found in Bauhinia saccocalyx roots and showed antimycobacterial activity [44]. 4-Hydroxycordoin is an isopentenyloxychalcone and has a clear ability against three major periodontal pathogen bacteria Prevotella intermedia, Porphyromonas gingivalis, and Fusobacterium nucleatum, as well anti-inflammatory effect [45]. Pterolinus D is one of benzofurans, was found in extract of Pterocarpus santalinus, Pterolinus D showed significant inhibition as an anti-inflammatory [46]. Abyssinone C isolated from Erythrina abyssinica and showed moderate cytotoxic activity against the human colorectal cancer cell line at IC50 15.1 µM [47]. The Blancoxanthone was isolated from Calophyllum blancoi and exhibited significant anti-coronavirus activity [48]. Brasixanthone B is a xanthones found for the first time in Calophyllum brasilienses and showed significant inhibitory activity against Epstein-Barr virus in Raji cells [49]. 4′-demethyldeoxypodophyllotoxin showed activity against the human epidermoid carcinoma and P-388 lymphocytic leukemia [50]. The kweichowenol B isolated from Uvaria kweichowensis leaves and showed antitumour activity based on yellow tetrazolium assay [51]. Erybraedin A had high activity against the BC and NCI-H187 cells (IC50 2.9 µg/ml of Erythrina stricta roots [52].

SEM analysis

The SEM observation showed varying damage to the surface microstructures of the plant cellular tissues due to different extraction methods between UMAE, MAE, and CSE. The combination of disruption of plant tissues by acoustic cavitation caused by ultrasonic/microwaves and solvent flow into plant cell tissues facilitated by thermal stress resulting from microwave irradiation can improve the effectiveness of extraction [14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53].

SEM images of treated and untreated Foshou fruit powder are shown in Fig. 3. Images of untreated Foshou fruit powder and powder after extraction by UMAE, MAE, and CSE under the optimized conditions are shown in Fig. 3a–d, respectively. The SEM images showed remarkable changes in the microstructure of the Foshou fruit powder samples after extraction. Ultrasonic/microwave-assisted extraction through the cavitation phenomenon helped to decaythe sample plant tissues, while microwave power led to further disintegration of the plant tissue. By contrast, the conventional solvent extraction had only a slight effect on the tissue microstructure, with no oserve of disintegration.

Conclusions

In conclusion, this investigation has enhanced green-procedures extraction to maximize the total phenolic content (TPC) yield from Foshou fruit using water as an environment-friendly solvent and ultrasonic/microwave-assisted as integrated technology. Response surface methodology based a Box-Behnken design was successfully used to optimize the performance of ultrasonic/microwave-assisted technique and enhance the extraction processes. Findings of this work showed that the integrated ultrasonic/microwave-assisted extraction was more efficient than the microwave-assisted extraction or conventional solvent extraction as obtaining the highest TPC yield and antioxidant activity from Foshou fruit. In sum, Foshou fruit can be considered a good source of TPC that possess a high antioxidant activity, and thus can be used as safe food additives instead of synthetic additives. In the same context, ultrasonic/microwave-assisted extraction can be used as a safe integrated technique that does not require the use of harmful solvents.

References

C. Ramadugu, M.L. Keremane, X. Hu, D. Karp, C.T. Federici, T. Kahn, M.L. Roose, R.F. Lee, Sci. Hortic. 195, 124–137 (2015)

Z. Wu, H. Li, Y. Yang, Y. Zhan, D. Tu, Ind. Crops Prod. 46, 311–316 (2013)

F. Shahidi, P. Ambigaipalan, J. Funct. Foods 18, 820–897 (2015)

M.M. Özcan, S. Doğu, N. Uslu, J. Food Meas. Charact. 12, 902–905 (2018)

L. Shen, H.F. Ji, H.Y. Zhang, Biochem. Biophys. Res. Commun. 362, 543–545 (2007)

K. Ameer, H.M. Shahbaz, J.H. Kwon, Compr. Rev. Food Sci. Food Saf. 16, 295–315 (2017)

M.L. Luna-Guevara, J.J. Luna-Guevara, P. Hernández-Carranza, H. Ruíz-Espinosa, C.E. Ochoa-Velasco, In: Studies in Natural Products Chemistry, ed. By A. Rahman (Elsevier B.V., 2018) p. 79

M. Plaza, C. Turner, Trends Anal. Chem. 76, 39–54 (2015)

B.K. Tiwari, Trends Anal. Chem. 71, 100–109 (2015)

S. Armenta, S. Garrigues, M. de la Guardia, TrAC, Trends Anal. Chem. 71, 2–8 (2015)

F. Chemat, N. Rombaut, A.G. Sicaire, A. Meullemiestre, A.S. Fabiano-Tixier, M. Abert-Vian, Ultrason. Sonochem. 34, 540–560 (2017)

Y. Liu, S. Wei, M. Wu, S. Yang, J. Food Meas. Charact. 12, 967–973 (2018)

J. Azmir, I. Zaidul, M. Rahman, K. Sharif, A. Mohamed, F. Sahena, M. Jahurul, K. Ghafoor, N. Norulaini, A. Omar, J. Food Eng. 117, 426–436 (2013)

H.K. Kala, R. Mehta, K.K. Sen, R. Tandey, V. Mandal, Trends Anal. Chem. 85, 140–152 (2016)

S. Prabakaran, L. Ramu, S. Veerappan, B. Pemiah, N. Kannappan, J. Food Meas. Charact. 11, 1531–1541 (2017)

J. Płotka-Wasylka, M. Rutkowska, K. Owczarek, M. Tobiszewski, J. Namieśnik, Trends Anal. Chem. 91, 12–25 (2017)

G. Brunner, J. Supercrit. Fluid 47, 373–381 (2009)

G. Astray, B. Gullón, J. Labidi, P. Gullón, Ind. Crops Prod. 92, 290–299 (2016)

S. Nag, N. Sit, J. Food Meas. Charact. 12, 1734–1743 (2018)

J.L. Pilkington, C. Preston, R.L. Gomes, Ind. Crops Prod. 58, 15–24 (2014)

P. Lucci, J. Saurina, O. Núñez, TrAC, Trends Anal. Chem. 88, 1–24 (2017)

A. Kaufmann, TrAC, Trends Anal. Chem. 63, 113–128 (2014)

F. Dahmoune, L. Boulekbache, K. Moussi, O. Aoun, G. Spigno, K. Madani, Ind. Crops Prod. 50, 77–87 (2013)

G. Spigno, L. Tramelli, D.M. De Faveri, J. Food Eng. 81, 200–208 (2007)

M.A. Bezerra, R.E. Santelli, E.P. Oliveira, L.S. Villar, L.A. Escaleira, Talanta 76, 965–977 (2008)

G.L. Chen, S.G. Chen, Y.Y. Zhao, C.X. Luo, J. Li, Y.Q. Gao, Ind. Crops Prod. 57, 150–157 (2014)

M.M. Rashed, Q. Tong, M.H. Abdelhai, M.A. Gasmalla, J.B. Ndayishimiye, L. Chen, F. Ren, Ultrason. Sonochem. 29, 39–47 (2016)

M.M. Rashed, Q. Tong, A. Nagi, J. Li, N.U. Khan, L. Chen, A. Rotail, A.M. Bakry, Ind. Crops Prod. 100, 236–245 (2017)

L. Zhang, Z.C. Tu, H. Wang, Z.F. Fu, Q.H. Wen, H.X. Chang, X.Q. Huang, Food Res. Int. 70, 101–109 (2015)

W. He, M. Zeng, J. Chen, Y. Jiao, F. Niu, G. Tao, S. Zhang, F. Qin, Z. He, J. Agric. Food Chem. 64, 171–177 (2015)

European Molecular Biology Laboratory European Bioinformatics Institute. http://www.ebi.ac.uk. Accessed 25 Feb 2017

Royal Society of Chemistry ChemSpider. http://www.chemspider.com. Accessed 25 Feb 2017

C. Proestos, M. Komaitis, LWT Food Sci. Technol. 41, 652–659 (2008)

H. Liu, N. Qiu, H. Ding, R. Yao, Food Res. Int. 41, 363–370 (2008)

G. Jayaprakasha, B.S. Patil, Food Chem. 101, 410–418 (2007)

S. Castillo, J. Dávila-Aviña, N. Heredia, S. Garcia, Food Sci. Biotechnol. 26, 453–459 (2017)

Y. Sun, L. Qiao, Y. Shen, P. Jiang, J. Chen, X. Ye, J. Food Sci. 78, 37–42 (2013)

F. Menichini, R. Tundis, M.R. Loizzo, M. Bonesi, D. D’Angelo, P. Lombardi, V. Mastellone, J. Enzyme Inhib. Med. Chem. 31, 1270–1276 (2016)

B. Orlikova, D. Tasdemir, F. Golais, M. Dicato, M. Diederich, Biochem. Pharmacol. 82, 620–631 (2011)

A.S. Wilkinson, M.W. Taing, J.T. Pierson, C.N. Lin, R.G. Dietzgen, P.N. Shaw, M.J. Gidley, G.R. Monteith, S.J. Robertsthomson, Food Funct. 6, 1847–1854 (2015)

L.Y. Tian, X. Bai, X.H. Chen, J.B. Fang, S.H. Liu, J.C. Chen, Phytomedicine 17, 533–539 (2010)

L.P. Qiu, K.P. Chen, Fitoterapia 84, 140–157 (2013)

M.M. Salem, K.A. Werbovetz, J. Nat. Prod. 68, 108–111 (2005)

P. Kittakoop, S. Nopichai, N. Thongon, P. Charoenchai, Y. Thebtaranonth, Helv. Chim. Acta 87, 175–179 (2004)

M. Feldman, S. Tanabe, F. Epifano, S. Genovese, M. Curini, D. Grenier, J. Nat. Prod. 74, 26–31 (2011)

S.F. Wu, F.R. Chang, S.Y. Wang, T.L. Hwang, C.L. Lee, S.L. Chen, C.C. Wu, Y.C. Wu, J. Nat. Prod. 74, 989–996 (2011)

L. Cui, P.T. Thuong, H.S. Lee, D. Njamen, J.T. Mbafor, Z.T. Fomum, J. Lee, Y.H. Kim, W.K. Oh, Planta Med. 74, 422–426 (2008)

Y.C. Shen, L.T. Wang, A.T. Khalil, L.C. Chiang, P.W. Cheng, Chem. Pharm. Bull. 36, 244–247 (2005)

I. Chihiro, I. Masataka, M. Yoshitaka, C.F. Valdir, M. Teruo, T. Harukuni, N. Hoyoku, F. Hiroshi, J. Nat. Prod. 65, 267–272 (2002)

R. Jiang, J.R. Zhou, P.M. Hon, S.L. Li, Y. Zhou, L.L. Li, W. Ye, H. Xu, P. Shaw, P.P. But, J. Nat. Prod. 70, 283–286 (2007)

Q.M. Xu, Z.M. Zou, L.Z. Xu, S.L. Yang, Chem. Pharm. Bull. 53, 826–828 (2005)

T. Rukachaisirikul, A. Saekee, C. Tharibun, S. Watkuolham, A. Suksamrarn, Arch. Pharmacal Res. 30, 1398–1403 (2007)

M.M. Rashed, A.D. Ghaleb, J. Li, A. Nagi, Y. Hua-wei, Z. Wen-you, Q. Tong, ACS Sustain. Chem. Eng. 6, 1639–1649 (2018)

Acknowledgements

This research was financially supported by the China Scholarship Council (CSC), Beijing, China and carried out in the Laboratory of the National Engineering Research Center for Functional Food at Jiangnan University, Wuxi, China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahdi, A.A., Rashed, M.M.A., Al-Ansi, W. et al. Enhancing bio-recovery of bioactive compounds extracted from Citrus medica L. Var. sarcodactylis: optimization performance of integrated of pulsed-ultrasonic/microwave technique. Food Measure 13, 1661–1673 (2019). https://doi.org/10.1007/s11694-019-00083-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00083-x