Abstract

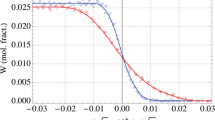

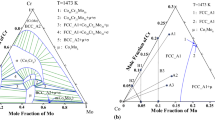

The interdiffusion behavior of ternary face-centered-cubic (fcc) Al-Co-Cr alloys has been studied by the diffusion-couple technique and CALculation of PHAse Diagram (CALPHAD) approach. The composition profiles of the fcc Al-Co-Cr diffusion couples at 1000 and 1200 °C were measured by using electron probe microanalysis (EPMA), followed by the extraction of interdiffusion coefficients through the Whittle-Green method. Based on the available thermodynamic description and diffusion coefficients in the literature as well as the experimental data obtained in the present work, the atomic mobilities of Al, Co, and Cr in fcc Al-Co-Cr alloys were assessed by means of the CALPHAD method. The diffusion coefficients, composition profiles and diffusion paths of fcc Al-Co-Cr alloys were calculated by adopting the atomic mobilities assessed in the present work, reaching a good agreement with the experimental data.

Similar content being viewed by others

References

J. Sato, T. Omori, K. Oikawa, I. Ohnuma, R. Kainuma, and K. Ishida, Cobalt-Base High-Temperature Alloys, Science, 2006, 312(5770), p 90–91.

Y. Li, F. Pyczak, M. Oehring, L. Wang, J. Paul, U. Lorenz, and Z. Yao, Thermal Stability of γ′ Phase in Long-term Aged Co-Al-W Alloys, J. Alloys. Compd., 2017, 729, p 266–276.

Z.D. Liang, M. Göken, U. Lorenz, S. Neumeier, M. Oehring, F. Pyczak, A. Stark, and L. Wang, Influence of Small Amounts of Si and Cr on the High Temperature Oxidation Behavior of Novel Cobalt Base Superalloys, Corros. Sci., 2021, 184, p 109388.

X.D. Xu, P. Liu, A. Hirata, S.X. Song, T.G. Nieh, and M.W. Chen, Microstructural Origins for a Strong and Ductile Al0.1CoCrFeNi high-Entropy Alloy with Ultrafine Grains, Materialia., 2018, 4, p 395–405.

S.K. Varma, F. Sanchez, S. Moncayo, and C.V. Ramana, Static and Cyclic Oxidation of Nb-Cr-V-W-Ta High Entropy Alloy in Air From 600 to 1400 °C, J. Mater. Sci. Technol., 2020, 38, p 189–196.

N. Kumar, M. Fusco, M. Komarasamy, R.S. Mishra, M. Bourham, and K.L. Murty, Understanding Effect of 3.5 wt.% NaCl on the Corrosion of Al0.1CoCrFeNi High-Entropy Alloy, J. Nucl. Mater., 2017, 495, p 154–163.

T. Gómez-Acebo, B. Navarcorena, and F. Castro, Interdiffusion in Multiphase, Al-Co-Cr-Ni-Ti Diffusion Couples, J. Phase Equilib. Diff, 2004, 25, p 237–251.

Y. Minamino, Y. Koizumi, N. Tsuji, T. Yamada, and T. Takahashi, Interdiffusion in Co Solid Solutions of Co–Al–Cr–Ni System at 1423 K, Mater Trans, 2003, 44, p 63–71.

J. Chen, J.K. Xiao, Z. Lu, C.Y. Wang, and L.J. Zhang, Atomic Mobilities and Interdiffusivities in Ni-rich fcc Ni-Co-Cr and Ni-Al-Co-Cr Systems Evaluated Using Composition Profiles and HitDIC, J. Alloys. Compd., 2021, 865, p 158645.

M. Abhishek, and S. Yongho, Investigation of Sluggish Diffusion in FCC Al0.25CoCrFeNi High-Entropy Alloy, Mater. Res. Lett, 2021, 9(5), p 239–246.

D.B. Miracle, and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448–511.

T.S. Cao, J.L. Shang, J. Zhao, C.Q. Cheng, R. Wang, and H. Wang, The Influence of Al Elements on the Structure and the Creep Behavior of AlxCoCrFeNi High Entropy Alloys, Mater. Lett., 2016, 164, p 344–347.

J.C. Rao, H.Y. Diao, V. Ocelík, D. Vainchtein, C. Zhang, C. Kuo, Z. Tang, W. Guo, J.D. Poplawsky, Y. Zhou, P.K. Liaw, and JTh.M. De Hosson, Secondary Phases in AlxCoCrFeNi High-Entropy Alloys: An In-Situ TEM Heating Study and Thermodynamic Appraisal, Acta Mater., 2017, 131, p 206–220.

K. Ishikawa, M. Ise, I. Ohnuma, R. Kainuma, and K. Ishida, Phase Equilibria and Stability of the bcc Aluminide in the Co-Cr-Al System, Phys. Chem., 1998, 102(9), p 1206–1210.

N. Dupin, and I. Ansara, Thermodynamic Assessment of the System Al–Co, Rev. Métall, 1998, 95, p 1121–1129.

N Saunders. 1991 Unpublished Revision Based on N Saunders, V.G. Rivlin. Z Metallkde 1987, 78, p. 795–801.

A. Kusoffsky, and B. Jansson, A Thermodynamic Evaluation of the Co-Cr and the C-Co-Cr Systems, Calphad, 1997, 21(3), p 321–333.

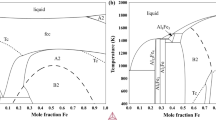

X.L. Liu, T. Gheno, B.B. Lindahl, G. Lindwall, B. Gleeson, and Z.-K. Liu, First-Principles Calculations, Experimental Study, and Thermodynamic Modeling of the Al-Co-Cr System, PLoS One, 2015, 10(4), p e0121386.

X.L. Liu, G. Lindwall, T. Gheno, and Z.K. Liu, Thermodynamic Modeling of Al–Co–Cr, Al–Co Ni, Co–Cr–Ni Ternary Systems Towards a Description for Al–Co–Cr–Ni, Calphad, 2016, 52, p 125–142.

I. Ansara, A.T. Dinsdale, and M.H. Rand, COST 507: Definition of Thermochemical and Thermophysical Properties to Provide a Database for the Development of New Light Alloys-Thermochemical Database for Light Metal Alloys. Office for Official Publications of the European Communities, Luxembourg, 1998.

G.W. Roper, and D.P. Whittle, Interdiffusion in Ternary Co-Cr-Al Alloys, Metal Sci., 1980, 14(1), p 21–28.

D.P. Whittle, and A. Green, The Measurement of Diffusion Coefficients in Ternary Systems, Scr. Metal., 1974, 8(7), p 883–884.

J.O. Andersson, and J. Ågren, Models for Numerical Treatment of Multicomponent Diffusion in Simple Phases, J. Appl. Phys., 1992, 72(4), p 1350–1355.

Y.W. Cui, K. Oikawa, R. Kainuma, and K. Ishida, Study of Diffusion Mobility of Al−Zn Solid Solution, J. Phase Equilib. Diff, 2006, 27, p 333–342.

L.J. Zhang, Y. Du, Y.F. Ouyang, H.H. Xu, X.G. Lu, Y. Liu, K. Yi, and J. Wang, Atomic Mobilities, Diffusivities and Simulation of Diffusion Growth in the Co–Si System, Acta Mater., 2008, 56, p 3940–3950.

A. Engström, and J. Ågren, Assessment of Diffusional Mobilities in Face-centered Cubic Ni-Cr-Al Alloys, Z. Metallkd, 1996, 87, p 92–97.

Y.W. Cui, B. Tang, R. Kato, R. Kainuma, and K. Ishida, Interdiffusion and Atomic Mobility for Face-Centered-Cubic Co-Al Alloys, Metall. Mater. Trans. A, 2011, 42, p 2542–2546.

R, Ohnuma, R. Kainuma, K. Ishida: Tohoku University, Sendai, Japan, unpublished research (2008)

N.L. Peterson, and S.J. Rothman, Impurity Diffusion in Aluminum, Phys. Rev. B, 1970, 1, p 3264–3273.

M.S. Anand, and R.P. Agarwala, Diffusion of Cobalt in Aluminium, Philos. Mag., 1972, 26, p 297–309.

G. Erdelyi, D.L. Beke, F.J. Kedves, and I. Godeny, Determination of Diffusion Coefficients of Zn, Co and Ni in Aluminium by a Resistometric Method, Philos. Mag. B, 1978, 38, p 445–462.

G.M. Hood, R.J. Schultz, and J. Armstrong, Co Tracer Diffusion in Al, Philos. Mag. A, 1983, 47, p 775–779.

G. Rummel, T. Zumkley, M. Eggersmann, K. Freitag, and H. Mehrer, Diffusion of Implanted 3d-Transition Elements in Aluminium Part I: Temperature Dependence, Z. Metallkd, 1995, 85, p 122–130.

W.B. Zhang, D.D. Liu, L.J. Zhang, Y. Du, and B.Y. Huang, Experiment Investigation and Computational Study of Atomic Mobility in fcc Ternatry Co-Cr-W, Calphad, 2014, 45, p 118–126.

J.W. Weeton, Chromium Diffusivity in Alpha-Cobalt-Chromium Solid Solutions, Trans. A.S.M, 1952, 44, p 436–451.

A. Davin, V. Leroy, D. Coutsouradis, and L. Habraken, Comparison of the Diffusion of Some Substitution Elements in Nickel and Cobalt, Cobalt, 1963, 19, p 51–56.

A. Green, D.P. Whittle, J. Stringer, and N. Swindells, Interdiffusion in the Cobalt-Chromium System, Scr. Metall., 1963, 7, p 1079–1082.

N. Zhao, W. Liu, J.J. Wang, X.G. Lu, and L.J. Zhang, Thermodynamic Assessment of the Ni–Co–Cr System and Diffusion Study of its fcc Phase, Calphad, 2020, 71, p 101996.

S. Neumeier, H.U. Rehman, J. Neuner, C.H. Zenk, S. Michel, S. Schuwalow, J. Rogal, R. Drautz, and M. Goken, Diffusion of Solutes in fcc Cobalt Investigated by Diffusion Couples and First Principles Kinetic Monte Carlo, Acta Mater., 2016, 106, p 304–312.

A. Engström, and J. Ågren, Assessment of Diffusional Mobilities in Face-Centered-Cubic Ni-Cr-Al Alloys, Z. Metallkd, 1996, 87, p 92–97.

Acknowledgments

The authors would like to acknowledge the financial support from the National Key R&D Program of China (Grant Number: 2017YFB0701904).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shang, G., Lu, Y., Wang, J. et al. Experimental and Computational Studies of Atomic Mobilities for fcc Al-Co-Cr Alloys. J. Phase Equilib. Diffus. 43, 471–482 (2022). https://doi.org/10.1007/s11669-022-00986-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-022-00986-1