Abstract

Diffusion couple experiments between various Co-rich face centered cubic (FCC) alloys in the Co-W-Al ternary system have been conducted at 900 and 1000 °C. Diffusion coefficients have been extracted for the Co-W binary and for ternary alloys at compositions where the diffusion paths cross. In addition, a least squares method has been utilized to optimize diffusion mobility parameters using DICTRA simulations to best fit the experimental concentration versus distance curves. Predictions of the diffusion matrix using the refined mobility database are in good agreement with the values obtained at the diffusion path crossing points.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In 2006 Sato et al.[1] identified the existence of a γ/γ′ microstructure in the Co-Al-W system, similar to that in the Ni-Al system that is used as the basis for many high temperature superalloys. The presence of the γ/γ′ microstructure in Co-based alloys has spurred several research efforts[2–5] to develop a new class of Co-based high temperature superalloys that have the potential to increase turbine engine operating temperature by 50 °C. Despite these efforts, only a limited number of research efforts have been focused on developing the thermodynamics[6–8] and diffusion descriptions.[9] Much of the current materials design work for these new Co-based superalloys is based on previous thermodynamic and diffusion assessments for the Ni-base superalloys and the cemented carbide systems.

Initial research on the stability of γ′ in the Co-Al-W system at 900 °C were inconclusive: Sato et al. initially reported the γ′ phase to be stable while work by Kobayashi and Tsukamoto[10,11] indicated the γ′ was not stable. To resolve this inconsistency, Lass et. al.[6] performed long time phase equilibria studies that confirmed that γ′ is not a stable phase at 900 °C in the Co-Al-W system. However, the metastable γ′ phase dissolves very slowly and remains present even after 4000 h at 900 °C. Based on these results, diffusion couple studies in the face centered cubic (FCC) phase region of the Co-Al-W system were initiated.

Literature Review

For the Co-Al, Co-W, Al-W and Co-Al-W systems, several experimental studies and assessments of the diffusion mobility as functions of composition and temperature have been reported in the literature. Peterson and Rothman,[12] Anand and Agarwala,[13] and Patvil and Tiwari[14] measured the Co impurity diffusion coefficient in the Al FCC phase. Green and Swindells,[15] Minamino et al.[16] and Cui et al.[17] have reported interdiffusion data for the Co-Al system in the FCC phase at temperatures from 900 to 1300 °C. Cui et al.[17] combined the available experimental data to develop composition-temperature dependent functions to describe the diffusion mobility in the Co-Al system for the FCC phase, following the methods outlined by Agren and co-workers.[18–20] The Co-W mobility functions in the FCC phase have been recently assessed by both Zhang et al.[21] and Cui et al.[22] Specific Al-W binary diffusion couple studies have not been reported, but both Chang et al.,[9] Obata et al.[23] Kobayashi et al.[10] investigated the ternary Co-Al-W system in the FCC phase region in the temperature range from 900 to 1300 °C. Other multicomponent diffusion-couple studies were conducted by G¢mez-Acebo et al.[24] who studied the Al-Co-Cr-Ni-Ti system and by Minamino et al. who studied the Co-Al-Cr-Ni system.[16] In addition the experimental diffusion work on Ni-base superalloys (including Co) prior to 2002 was summarized by Campbell et al.[25] and a database of composition and temperature dependent mobility functions was constructed. Table 1 summarizes the diffusion mobility parameters reported in these previous assessments.[9,21,24,25] The diffusion mobility assessments reported for the Ni-base superalloy systems[25] were used as initial values for the re-optimization of mobility parameters in this work.

Experimental Procedure

To study the diffusion mobilities in the Co-Al-W system in the single-phase FCC region, diffusion couples were assembled using end members with the following nominal compositions in mole fraction:

-

Co (a) versus Co-0.025 W (d)

-

Co (a) versus Co-0.080 Al-0.040 W (c)

-

Co-0.025 W (d) versus Co-0.085 Al (i)

-

Co-0.085 Al (i) versus Co-0.050 W (j)

-

Co-0.025 W (d) versus Co-0.080 Al-0.040W (c).

The bold lower case letters will be used as an alloy designation. These combinations of compositionsFootnote 1 yielded several ternary diffusion path crossover compositions (see Fig. 4).

The end member alloys were arc melted from Co, Al, and W elements, with purities in mass fractions of 99.9%, 99.999%, and 99.97%, respectively. The measured end member alloy compositions and homogenization conditions are summarized in Table 2. As the research progressed, additional ingots were made (designated with primes) and the homogenization treatment altered. The diffusion couple experiments for which the end members were used are listed in the Table 3. The homogenization time and temperatures for the second ingots were increased because of the difficulty of obtaining uniform W profiles due to residual dendritic micro-segregation resulting from the arc casting. Even after the higher temperature treatment a small amount of micro-segregation remained. For example for the Co-0.05 W mole fraction end member, a variation of ±0.0011 mole fraction W (2σ) remained on an approximate length scale of 40 μm.

The treated ingots were cut into rectangular pieces 9 mm × 9 mm × 5 mm or 11 mm × 11 mm × 10 mm approximately. Two adjacent faces of the pieces were ground and polished to a finish obtained with 1 μm diamond suspension. Columnar stacks of the various alloys up to six pieces were assembled. For the 900 °C diffusion experiment, stacks were loaded vertically with a 315 g weight and annealed in a vacuum furnace for either 477 or 580 h as indicated in Table 3. A Mo-alloy clamp was used for the stack annealed at 1000 °C for 240 h in a vacuum ampule.

After the diffusion treatment, the stacks were mounted in epoxy, sectioned parallel to the columnar direction, ground and polished. All diffusion couples were examined by SEM microscopy for quality of the bond regions. The grain size was noted to be larger than 250 µm so that grain boundary diffusion could be neglected. Composition profiles were measured using a JEOL JSM-7100 FE-SEM with an Oxford Instruments X- Maxn 80 silicon drift detector.Footnote 2 The FE-SEM conditions were 15 keV and 1.0 nA. The acquisition times were chosen as 1000 s for elemental standards and 400 s for samples. The Co K, W L, and Al K lines were used. The penetration profiles of each diffusion couple were measured along 4-5 parallel lines using the point analysis mode across the diffusion zone with steps of 2 and 5 µm for the regions inside and outside of the diffusion zone, respectively. A typical example of the location of the line scans is shown in Fig. 3, where the dark spots from carbon deposits by the e-beam, represent measured positions.

The composition analysis was performed with Oxford Aztec software using elemental standards. The software provided the estimated standard deviation of the composition measurements in mass fraction, which was converted to mole fraction. A typical example of the standard deviation for the ac couple (900 °C) couple, gives the following. At the pure Co end, the measured composition with its standard deviation was (0.001 ± 0.0002) mole fraction of Al and (0.001 ± 0.0004) mole fraction of W. At the alloy end, the measured composition with its standard deviation was (0.080 ± 0.0004) mole fraction of Al and (0.04 ± 0.0005) mole fraction of W.

Data Smoothing

Data smoothing is required especially due to the composition variation in the W profiles in the end members and because differentiation of the penetration curves is required. Each data set, composition versus distance, was noise filtered using a discrete Fourier Gauss filter with 1 μm full width half maximum (FWHM) approximately and was repeated 5-15 times. Repeating the filtration process using a smaller FWHM showed a better result than a single process using a larger FWHM. The smaller FWHM reduced the scatter but retained the characteristics of the penetration curves. A Fourier series function was used to fit the data in the diffusion zone. This function was truncated at the position where it intersected the constant end member composition values obtained by averaging over a suitable distance range using data outside the diffusion zone. This composite function was then splined.

The Matano interface position was computed using the splined data by the usual method. Then, the distance coordinate of each line scan was shifted so that its Matano position was assigned the value of zero. The x-distance corrected experiment data for the parallel line scans were merged into a single set. This single data set is defined as the merged data. The whole smoothing process was re-applied to this merged data for the noise reduction and a single splined data set was obtained. This final splined data was used to calculate diffusivities and to optimize the CALPHAD mobility database as described later.

Experimental Results

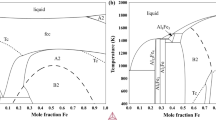

All diffusion couples consisted of only the FCC phase. The results for 900 and 1000 °C are given in Fig. 1-5. Fig. 1 shows the W penetration curves in W mole fraction versus scaled distance \( z/\sqrt t \) for the binary Co-W diffusion couples where t is the diffusion time and z is the spatial coordinate. The blue color represents diffusion couples annealed at 900 °C, and the red color represents diffusion couples annealed at 1000 °C. The circles represent the merged data, and the solid lines represent the splined data. Figure 2 shows the Al and W penetration curves for the ternary diffusion couples. Figure 3 shows an example of a micrograph of the diffusion zone in the ternary couple (di) after the 1000 °C treatment. The structure is featureless and clearly single phase. The spots of the microprobe analysis are visible as is a rectangular region where a detailed examination of the bond region was conducted. Figure 4 shows the diffusion paths, Al composition versus W composition for the ternary couples and Figure 5 shows a magnified view of the central portion of the paths and the location of the intersection compositions to be used for the determination of the ternary interdiffusion matrix as described below.

A typical microstructure of Co-0.025W vs. Co-0.085Al (di) diffusion couple boundary annealed at 1000 °C for 240 h. Dark spots, carbon contaminants by e-beam, represent measured positions. Penetration profiles were measured five times by a line scan using a point analysis mode across the diffusion zone by steps of 2 and 5 µm

Diffusion paths of Co vs. Co-0.080Al-0.040W (ac), Co-0.025W vs. Co-0.085Al (di), Co-0.050W vs. Co-0.085Al (ij), and Co-0.025W vs. Co-0.080Al-0.040W (dc) diffusion couples annealed at 900 °C for 477 h (open circle) and at 1000 °C for 240 h (filled circle). Circles represent the merged data and lines represent the splined curve. Only the diffusion path annealed at 1000 °C for 240 h of the cd couple is presented in this figure. The area of dashed square is enlarged in Fig. 5

Enlarged figure of rectangular area in Fig. 4 showing crossover positions of the various diffusion paths at the two annealing temperatures. Intersection points are labeled according the couples and temperatures. Circles represent the merged data and lines represent the splined curve

Analysis Methods

The variation of molar volume with composition was neglected in this research. The assessment of molar volume of the Co-Al-W FCC alloys[37] gives a variation of molar volume of 2.2% from pure Co to Co-0.08Al-0.04W (ac). The interdiffusion flux of a component as a function of distance was obtained using the Sauer-Freise formalism applied to interpolation functions obtained from the penetration curves. For the ternary system, the flux \( J_{i} \) of each component as a function of position z for constant molar volume is evaluated from

and is related to the diffusion coefficients using

where t is the diffusion time, \( V_{m} \) is the molar volume, i is element (i = 1, 2), \( x_{i}^{L} \) and \( x_{i}^{R} \) are the left (−∞) and right (+∞) terminal mole fractions and \( \tilde{D}_{i1}^{3} \) and \( \tilde{D}_{i2}^{3} \)are mole fraction diffusivities.[38] For the binary system, the interdiffusion coefficient \( D \) is estimated from

where t is the diffusion time, and x L and x R are the left (−∞) and right (+∞) terminal mole fractions.

The concentration gradients were obtained from the splined data. For the binary couple, the value of the interdiffusion coefficient was obtained at each position by dividing the flux by the negative of the gradient. Hall’s method could not be used near the end member compositions due to the scatter in the data.

For the ternary samples, the method of crossing diffusion paths was used to determine the values of the interdiffusion coefficient (\( \tilde{D} \)) matrix at the intersection composition with Co considered as the dependent component. The interdiffusion fluxes of Al and W for the two crossing paths were calculated as a function of spatial position using Eq 1. The positions corresponding to the compositional intersection of the paths was obtained and the fluxes evaluated there. The four concentration gradients of Al and W at the two intersection points were determined. A system of two pairs of two linear equations were solved for the four D values, \( \tilde{D}_{\text{AIAI}}^{\text{Co}} \), \( \tilde{D}_{\text{AIW}}^{\text{Co}} \), \( \tilde{D}_{\text{WAI}}^{\text{Co}} \), and \( \tilde{D}_{\text{WW}}^{\text{Co}} \). Mathematica scripts were employed for these methods.

A CALPHAD-approach as outlined by Ågren and co-workers[18,19,39] was used to model the composition and temperature dependent atomic diffusion mobilities in the substitutional FCC solid solution. Using this approach, the chemical diffusivity in the volume-fixed frame of reference is defined as:

where δ ik = 1 when i = k and δ ik = 0 when i ≠ k, μ i is the chemical potential of element i and x i is the mole fraction of element i, and M i is the atomic mobility. The atomic mobility depends on composition and temperature of is

where R is the gas constant, T is temperature, \( M_{i}^{0} \) is a frequency factor which includes the atomic jump distance and frequency, and ∆Q i is an activation energy, which is temperature and composition dependent. For a disordered solid solution phase, the composition dependence of the diffusion mobility is represented using Redlich-Kister[40] polynomials for binary terms and a power series expansion for ternary terms.

where \( v_{pqv}^{s} = x_{s} + {{\left( {1 - x_{p} - x_{q} - x_{v} } \right)}}/{3} \) with \( s \in \left( {p,q,v} \right) \), where \( Q_{i}^{P} \) is the self-activation energy for component i in a given phase and \( ^{r} A_{i}^{pq} \) and \( ^{s} B_{i}^{pqv} \) are binary and ternary interaction parameters, respectively. It should be noted in this work no ternary interaction parameters were considered. The composition dependence of the frequency factor can be represented in the form of Eq 6; however, it is assumed that \( M_{i}^{0} \) is exponentially dependent on composition[41] and is included in the activation energy term[20,25]

Initial estimates for the mobilities terms (\( Q_{i}^{P} \) and \( ^{r} A_{i}^{pq} \)) were taken from the NIST Ni mobility database[25,26] given in column 3 of Table 1. The self-diffusion mobility parameters for Co, Al and W (\( Q_{\text{Al}}^{\text{Al}} \), \( Q_{\text{Co}}^{\text{Co}} \) and \( Q_{\text{W}}^{\text{W}} \)) were held constant as these values have been previously established. Using the experimental the ternary ac, di, and ij and binary ad diffusion couple results and the Co-Al binary diffusion data from Cui et al.,[17] the initial diffusion mobility parameters were optimized comparing the experimental and calculated diffusion composition profiles. The diffusion simulations were performed using the DICTRA[42] finite-difference code in conjunction with the thermodynamic database by Kattner.[27] All of the simulations used a double geometric grid with 200 points and exponents of 0.98 and 1.02 for the lower and upper parts of geometrical series, respectively. The simulated region was 400 µm in length.

Initially the diffusion mobility parameters were optimized by simultaneously comparing nine calculated penetration curves at 900 °C (one curve for each of the three elements of three diffusion couples) to the experimental penetration curves. It should be noted that this optimization does not include any temperature dependence. A sum of square error matrix was constructed, and selected ternary mobility parameters were varied to minimize the matrix. Best results were obtained with optimizations done one mobility parameter at a time and then repeated sequentially with the other parameters until a reasonable fit was found. After this procedure, a minimization was employed simultaneously varying all of the mobilities to determine the global optimum parameters. The same process was repeated to determine optimized mobilities for the 1000 °C diffusion experiments. The resulting sets of diffusion mobility parameters from the 900 and 1000 °C optimizations were combined assuming linear temperature dependence.

The optimized values of the diffusion mobility parameters are given in Table 1. The current optimization includes only the revisions to the terms that represent impurity diffusion in the pure elements and no binary interaction terms. The changes to the pure element terms are generally within 20% of the original value. The largest changes were to the mobility of Al and W in a pure Co matrix. Previous assessments by Cui et al.[8] and Zhang et al.[21] included binary interactions parameters. The current work determined that these binary interaction parameters were not needed to obtain a fit to the data within the experimental error. The dependence of the optimized mobility parameters on the thermodynamic databases was also evaluated. The chemical diffusion (interdiffusion) coefficients calculated using Ni thermodynamic database by Thermotech[43] were equivalent to those calculated using the thermodynamics from Ref 27.

Results and Discussion

Binary Diffusion Coefficients for Co-W

Figure 6 shows the value of the interdiffusion coefficient versus composition obtained from the Co versus Co-0.025W diffusion couple at 900 and 1000 °C using the Sauer-Freise method. The error bars represent the maximum and minimum diffusion coefficients determined from interpolation of four-measured penetration curves at the W compositions. We note a decreasing trend with increasing W content x W, given by the equation, \( \tilde{D} \left({m^2/s}\right)= 1.11 \times 10^{ - 17} - 1.88 \times 10^{ - 16} \,x_{\text{W}} \) for 900 °C and \( \tilde{D} \left({m^2/s}\right)= 7.05 \times 10^{ - 17} - 1.80 \times 10^{ - 15} \,x_{\text{W}} \) for 1000 °C. The decreasing trend of the diffusion coefficient with W content is consistent with the data of Cui et al.[22] obtained between 1000 and 1300 °C. An Arrhenius fit of their data at pure Co (the W impurity diffusion in pure Co) yields \( D_{0} = 5.85 \times 10^{ - 5} \,{\text{m}}^{2} / {\text{s}} \) and Q = 291.8 kJ/mol·K giving a value of 7 × 10−18 m2/s at 900 °C and 6 × 10−17 m2/s at 1000 °C. The present work extrapolated to pure Co gives values of 1.11 × 10−17 m2/s at 900 °C and 7.05 × 10−17 m2/s at 1000 °C.

Interdiffusion coefficients vs. W composition at 1000 °C (red) and 900 °C (blue) using the Sauer-Freise method (open circle). Dot-dashed lines represent the interdiffusion coefficients calculated by DICTRA using initial mobility parameters and the dashed lines represent interdiffusion coefficients using optimized mobility parameters. The solid lines are the linear fits of the Sauer-Freise calculated interdiffusion coefficients. Solid black symbols are from data of Cui et al.[22] Note that interdiffusion coefficients for 1000 °C calculated by DICTRA using initial and optimized parameters are overlapped

Ternary Diffusion Coefficients for Co-Al-W from Crossing Paths

Table 4 gives the values of the four diffusion coefficients determined at the three crossing compositions for diffusion couples ac-ij and ac-di at 900 °C and ac-ij, ac-di and cd-ij 1000 °C. Also listed are the values of the D matrix at the crossing composition obtained from DICTRA using the initial and optimized mobility parameters. The procedure to obtain the optimized mobilities is described below.

An estimate of the experimental standard error (2σ) for the values of D extracted from the crossing points is given in Table 4. This estimate was determined by employing the intersection method using the individual (non-merged) experimental data and also data smoothed by the method explained in section 3. While the values of the diagonal coefficients are determined with good confidence, the values of the off-diagonal coefficients are less certain. Indeed, for the value of \( \tilde{D}_{\text{AlW}}^{\text{Co}} \), one cannot be certain of the sign.

Ternary Mobility Parameters for Co-Al-W

Figure 7 compares the experimental penetration curves to the calculated penetration curves using the initial and optimized mobility databases for the binary diffusion couples, and Fig. 8 and 9 shows the same information for the ternary diffusion couples. The fits to the experimental penetration curves using the optimized mobility parameters are much improved.

Comparison between experiment data and calculated data from DICTRA for Co vs. Co-0.025W (ad) diffusion couples at 900 °C (blue) and 1000 °C (red). Circles represent the merged data, lines represent the splined curves, dot-dashed lines represent calculated penetration curves using initial parameters of mobility, and dashed lines represent penetration curves using optimized parameters of mobility

(a) Comparison between experiment data and calculated data from DICTRA for Co vs. Co-0.080Al-0.04W (ac) diffusion couples at 900 °C (blue) and 1000 °C (red). Circles represent the merged data, lines represent the splined curves, dot-dashed lines represent calculated penetration curves using initial parameters of mobility, and dashed lines represent penetration curves using optimized parameters of mobility. (b) Same for Co-0.025W vs. Co-0.085Al (di) diffusion couples. Note that the discontinuity of both calculated W penetration curve for 900 °C comes from the Curie point.

(a) Comparison between experiment data and calculated data from DICTRA for Co-0.085Al vs. Co-0.050W (ij) diffusion couples at 900 °C (blue) and 1000 °C (red). Circles represent the merged data, lines represent the splined curves, dot-dashed lines represent calculated penetration curves using initial parameters of mobility, and dashed lines represent penetration curves using optimized parameters of mobility. (b) Same for Co-0.080Al-0.040W vs. Co-0.025W (cd) diffusion couples at 1000 °C (red)

The calculated D values at the crossing compositions using the optimized mobility parameters are given in Table 4. The calculated values are in the correct ranges but lie outside of the estimated standard errors for the experimentally determined diffusion coefficients. The diagonal terms of the diffusion matrix agree within 80% at 900 °C and 25% at 1000 °C. The off-diagonal terms have the correct signs at 900 °C, but the signs are uncertain for several terms at 1000 °C.

Figure 10 and 11 shows contour maps of the four diffusion coefficients at 900 and 1000 °C calculated with the optimized mobility database. The values obtained from the crossing point procedure are indicated in red. Large variations of the D values with composition are apparent. As is well known, as one approaches the Co-W binary side of the Co-Al-W ternary, the value of \( \tilde{D}_{\text{AlW}}^{\text{Co}} \) must vanish, and as one approaches the Co-Al side of the diagram, the value of \( \tilde{D}_{\text{AlW}}^{\text{Co}} \) must vanish. These properties are evident in the figure. Large changes in values of the D matrix occur at the dashed line in Fig. 10 and 11. For the temperature of the diffusion experiments, the dashed lines indicate the composition boundary between ferromagnetic FCC phase and paramagnetic FCC phase obtained from the thermodynamic assessment.

Diffusivity contour maps for 900 °C of FCC-gamma phase region using interdiffusion coefficients from DICTRA-Poly 3. Red dots are interdiffusion coefficients calculated by Sauer-Freise method, and values are interdiffusion coefficients listed in Table 4

Diffusivity contour maps for 1000 °C of FCC-gamma phase region using interdiffusion coefficients from DICTRA-Poly 3. Red dots are interdiffusion coefficients calculated by Sauer-Freise method, and values are interdiffusion coefficients listed in Table 4

The uncertainty of the experimentally determined sign of \( \tilde{D}_{\text{AlW}}^{\text{Co}} \) is reflected in the fact that the calculated value switches sign with small changes in the composition (ac-ij to cd-ij intersections) as seen in the contour map of \( \tilde{D}_{\text{AlW}}^{\text{Co}} \) in Fig. 10 and 11. The predicted \( \tilde{D}_{\text{AlW}}^{\text{Co}} \) at the crossover compositions are close to zero, and the zero value contour lines are shifted depending on the temperature.

Conclusion

Diffusion couple experiments between various face centered cubic alloys in the Co-W-Al ternary system have been conducted at 900 and 1000 °C. Diffusion coefficients have been extracted for the Co-W binary and for the ternary alloys at compositions where the diffusion paths cross. In addition, a least squares method has been utilized to optimize diffusion mobility parameters for DICTRA simulations to best fit the experimental concentration versus distance curves. Predictions of the diffusion coefficient matrix using the refined mobility database compare with the values obtained at the diffusion path crossing points as follows. The diagonal terms of the diffusion matrix agree within 80% at 900 °C and 25% at 1000 °C. The off-diagonal terms have the correct signs at 900 °C, but signs are uncertain for several at 1000 °C.

Notes

Note all compositions are given in mole fraction, unless otherwise stated.

Commercial names are used for completeness and do not constitute an endorsement from NIST.

References

J. Sato, T. Omori, K. Oikawa, I. Ohnuma, R. Kainuma, and K. Ishida, Cobalt-Base High-Temperature Alloys, Science, 2006, 312, p 90-91

T. Pollock, J. Dibbern, M. Tsunekane, J. Zhu, and A. Suzuki, New Co-Based γ-γ′ High-Temperature Alloys, JOM, 2010, 62, p 58-63

F. Xue, H.J. Zhou, X.F. Ding, M.L. Wang, and Q. Feng, Improved High Temperature γ′ Stability of Co-Al-W-Base Alloys Containing Ti and Ta, Mater. Lett., 2013, 112, p 215-218

M.S. Titus, A. Suzuki, and T.M. Pollock, Creep and Directional Coarsening in Single Crystals of New γ-γ′ Cobalt-Base Alloys, Scr. Mater., 2012, 66, p 574-577

S.K. Makineni, B. Nithin, and K. Chattopadhyay, A New Tungsten-Free γ-γ′ Co-Al-Mo-Nb-Based Superalloy, Scr. Mater., 2015, 98, p 36-39

E.A. Lass, M.E. Williams, C.E. Campbell, K.W. Moon, and U.R. Kattner, γ′ Phase Stability and Phase Equilibrium in Ternary Co-Al-W at 900 A degrees C, J. Phase Equilib. Diffus., 2014, 35, p 711-723

J. Zhu, M.S. Titus, and T.M. Pollock, Experimental Investigation and Thermodynamic Modeling of the Co-Rich Region in the Co-Al-Ni-W Quaternary System, J. Phase Equilib. Diffus., 2014, 35, p 595-611

Y.F. Cui, X. Zhang, G.L. Xu, W.J. Zhu, H.S. Liu, and Z.P. Jin, Thermodynamic Assessment of Co-Al-W System and Solidification of Co-Enriched Ternary Alloys, J. Mater. Sci., 2011, 46, p 2611-2621

H. Chang, G. Xu, X.-G. Lu, L. Zhou, K. Ishida, and Y. Cui, Experimental and Phenomenological Investigations of Diffusion in Co-Al-W alloys, Scr. Mater., 2015, 106, p 13-16

S. Kobayashi, Y. Tsukamoto, T. Takasugi, H. Chinen, T. Omori, K. Ishida, and S. Zaefferer, Determination of phase equilibria in the Co-rich Co-Al-W ternary system with a diffusion-couple technique, Intermetallics, 2009, 17, p 1085-1089

Y. Tsukamoto, S. Kobayashi, and T. Takasugi, The Stability of γ′-Co(3)(Al, W) Phase in Co-Al-W Ternary System, Pricm 7, Pts 1-3, J.F. Nie and A. Morton, Ed., Trans Tech Publications Ltd, Stafa-Zurich, 2010, p 448-451

N.L. Peterson and S.J. Rothman, Impurity Diffusion in Aluminum, Phys. Rev. B, 1970, 1, p 3264-3273

M.S. Anand and R.P. Agarwala, Diffusion of Cobalt in Aluminum, Philos. Mag., 1972, 26, p 297-309

R.V. Patil and G.P. Tiwari, Diffusion of Cobalt in Aluminium, Trans. Indian Inst. Met., 1974, 27, p 215-220

A. Green and N. Swindells, Measurement of Interdiffusion Coefficients in Co-Al and Ni-Al Systems Between 1000 and 1200 °C, Mater. Sci. Technol., 1000, 1(1985), p 101-103

Y. Minamino, Y. Koizumi, N. Tsuji, T. Yamada, and T. Takahashi, Interdiffusion in Co Solid Solutions of Co-Al-Cr-Ni System at 1423 K, Mater. Trans., 2003, 44, p 63-71

Y.W. Cui, B. Tang, R. Kato, R. Kainuma, and K. Ishida, Interdiffusion and Atomic Mobility for Face-Centered-Cubic Co-Al Alloys, Mater. Trans. A., 2011, 42A, p 2542-2546

J. Ågren, Numerical Treatment of Diffusional Reactions in Multicomponent Alloys, J. Phys. Chem. Solids, 1982, 43, p 385-391

J. Ågren, Diffusion in Phases with Several Components and Sublattices, J. Phys. Chem. Solids, 1982, 43, p 421-430

J.-O. Andersson and J. Ågren, Models for Numerical Treatment of Multicomponent Diffusion in Simple Phases, J. Appl. Phys., 1992, 72, p 1350-1355

W.B. Zhang, D.D. Liu, L.J. Zhang, Y. Du, and B.Y. Huang, Experimental Investigation and Computational Study of Atomic Mobility in FCC Ternary Co-Cr-W Alloys, Calphad Comput. Coupling Phase Diagr. Thermochem., 2014, 45, p 118-126

Y.W. Cui, G. Xu, R. Kato, X.-G. Lu, R. Kainuma, and K. Ishida, Interdiffusion and Atomic Mobility for FCC-Centered Cubic (FCC) Co-W Alloys, Metall. Mater. Trans., 2013, 44A, p 5

S. Obata, M. Moniruzzaman, and Y. Murata, Interdiffusion in Co-Based Co-Al-W Ternary Alloys at Elevated Temperatures, ISIJ Int., 2014, 54, p 2129-2133

T. G¢mez-Acedbo, B. Navarcorena, and F. Castro, Interdiffusion in Multiphase, Al-Co-Cr-Ni-Ti Diffusion Couples, J. Phase Equilib. Diffus., 2004, 25, p 237-251

C.E. Campbell, W.J. Boetttinger, and U.R. Kattner, Development of a Diffusion Mobility Database for Ni-Base Superalloys, Acta Mater., 2002, 50, p 775-792

C.E. Campbell, J.C. Zhao, and M.F. Henry, Comparison of Experimental and Simulated Multicomponent Ni-Base Superalloy Diffusion Couples, J. Phase Equilib. Diffus., 2004, 25, p 6-15

U.R. Kattner, Construction of a Thermodynamic Database for Ni-base Superalloys: A Case Study, CALPHAD and Alloy Thermodynamics, P.E.A. Turchi, A. Gonis, and R.D. Shull, Ed., TMS, Warrendale, PA, 2002, p 147-164

I. Ansara, A.T. Dinsdale, and M.H. Rand, COST 507, Thermochemical Database for Light Metal Alloys, Ver. 2, Office for Official Publications of the European Communities, Luxembourg, 1998, p 103-108

Y. Peng, Y. Du, P. Zhou, W. Zhang, W. Chen, L. Chen, S. Wang, G. Wen, and W. Xie, CSUTDCC1—A Thermodynamic Database for Multicomponent Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2014, 42, p 57-70

Y.W. Cui, K. Oikawa, R. Kainuma, and K. Ishida, Study of Diffusion Mobility of Al-Zn Solid Solution, J. Phase Equilib. Diffus., 2006, 27, p 333-342

A. Engström and J. Ågren, Assessment of Diffusional Mobilities in Face-ceneterd Cubic Ni-Cr-Al Alloys, Z. Metall., 1996, 87, p 92-97

Y.W. Cui, M. Jiang, I. Ohnuma, K. Oikawa, R. Kainuma, and K. Ishida, Computational Study of Atomic Mobility for FCC Phase of Co-Fe and Co-Ni Binaries, J. Phase Equilib. Diffus., 2008, 29, p 2-10

L. Zhang, Y. Du, Y. Ouyang, H. Xu, X.G. Lu, Y. Liu, Y. Kong, and J. Wang, Atomic Mobilities, Diffusivities and Simulation of Diffusion Growth in the Co-Si System, Acta Mater., 2008, 56, p 3940-3950

N. Dupin and B. Sundman, A Thermodynamic Database for Ni-Base Superalloys, Scand. J. Metall., 2001, 30, p 184-192

N. Dupin and I. Ansara, Thermodynamic Assessment of the System Al-Co, Rev. Metall., 1998, 95, p 1121-1129

J. Sato, K. Oikawa, R. Kainuma, and K. Ishida, Experimental Verification of Magnetically Induced Phase Separation in αCo Phase and Thermodynamic Calculations of Phase Equilibria in the Co-W System, Mater. Trans., 2005, 46, p 1199-1207

E. Lass, Molar Volume Assessment, Unpublished Research, NIST, Gaithersburg, MD, 2015, p 20899

J.E. Morral, Chemical Diffusivities and their Hidden Concentration Units, J. Phase Equilib. Diffus., 2014, 35, p 581

B. Jonsson, Assessment of the Mobilities of Cr, Fe and Ni in bcc Cr-Fe-Ni Alloys, ISIJ International, 1995, 35, p 1415-1421

O. Redlich and A. Kister, Algebraic Representation of Thermodynamic Properties and the Classification of Solutions, Ind. Eng. Chem., 1948, 40, p 345-348

B. Jönsson, Assessment of the Mobilities of Cr, Fe, and Ni in FCC Cr-Fe-Ni Alloys, Z. Metallkunde, 1995, 86, p 686-692

DICTRA, Thermo-Calc AB, DICTRA, Stockholm, Sweden, 2003

N. Saunders, Phase Diagram Calculations for Ni-Based Superalloys, Superalloys 1996, R.D. Kissinger, Ed., TMS, Warrendale, PA, 1996, p 101-110

Acknowledgment

William J. Boettinger acknowledges support from the U.S. Department of Commerce, National Institute of Standards and Technology, under financial assistance award 70NANB15H279.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moon, K.W., Campbell, C.E., Williams, M.E. et al. Diffusion in FCC Co-rich Co-Al-W Alloys at 900 and 1000 °C. J. Phase Equilib. Diffus. 37, 402–415 (2016). https://doi.org/10.1007/s11669-016-0486-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-016-0486-7