Abstract

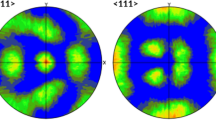

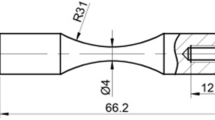

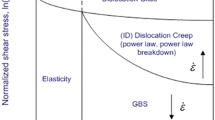

A continuum damage mechanics (CDM) model for high-cycle fatigue (HCF) is presented to study crack initiation in AA7075-T651. This study is based on the experimental observation of dependence of crack initiation life on microstructure of alloys. We investigate the effect of microstructural features such as grain size and grain orientation on crack initiation life. A crystal plasticity finite element model (CPFEM) is implemented in conjunction with CDM model to simulate damage evolution at grain scale. Finite element program ABAQUS has been used and the CPFEM–CDM model is written using a user material subroutine. Simulations are performed for constant amplitude, completely reversed loading. In order to provide a prediction for fatigue scatter, we consider different realizations of the microstructure as well as uncertainty in fatigue parameters. Given probability density function of damage parameters, we can transport it into a lifetime probability density function using simulations results. Good agreement is observed between simulations results and available experimental data. Further investigation is needed to develop the CPFEM–CDM model for HCF under variable loading conditions.

Similar content being viewed by others

References

L.M. Kachanov, Rupture time under creep conditions. Izv. Akad. Nauk. SSSR 8, 26–31. Reprinted from: Int. J. Fract., 97, 11–18 (1958)

J. Lemaitre, J.L. Chaboche, Mechanics of Solid Materials (Cambridge University Press, Cambridge, 1990)

J.L. Chaboche, Continuous damage mechanics: a tool to describe phenomena before crack initiation. Nucl. Eng. Des. 64, 233–247 (1981)

J.L. Chaboche, Continuum damage mechanics. I-General concepts. II-Damage growth, crack initiation, and crack growth. ASME, Transactions. J. Appl. Mech. 55, 59–72 (1988)

J. Lemaıtre, A continuum damage mechanics model for ductile fracture. J. Eng. Mater. Technol. 107, 83–89 (1985)

D. Krajcinovic, Damage Mechanics (North-Holland, Amsterdam, 1996)

M. Boudifa, K. Saanouni, J.L. Chaboche, A micromechanical model for inelastic ductile damage prediction in polycrystalline metals for metal forming. Int. J. Mech. Sci. 51, 453–464 (2009)

A.L. Gurson, Continuum theory of ductile rupture by void nucleation and growth: Part 1—yield criteria and flow rules for porous ductile media. J. Eng. Mater. Sci. Technol. 99, 2–15 (1977)

T.H. Lin, Analysis of elastic and plastic strains of face centered cubic crystal. J. Mech. Phys. Solids 5, 143–149 (1957)

M. Gologanu, J.B. Leblond, G. Perrin, J. Devaux, Recent extensions of Gurson’s model for porous ductile metals, in Continuum Micro-mechanics, CISM Courses and Lectures 377, ed. by P. Suquet (Springer, Berlin, 1997), pp. 61–130

M. Amiri, S. Modarres, Short fatigue crack initiation and growth modeling in aluminum 7075-T6. J. Mech. Eng. Sci. (2014). doi:10.1177/0954406214546880

M. Naderi, S.H. Hosseini, M. Khonsari, Probabilistic simulation of fatigue damage and life scatter of metallic components. Int. J. Plast. 43, 101–115 (2013)

Y. Jiang, W. Ott, C. Baum, M. Vormwald, H. Nowack, Fatigue life predictions by integrating EVICD fatigue damage model and an advanced cyclic plasticity theory. Int. J. Plast 25, 780–801 (2009)

G. Kang, Y. Liu, J. Ding, Q. Gao, Uniaxial ratcheting and fatigue failure of tempered 42CrMo steel: damage evolution and damage-coupled visco-plastic constitutive model. Int. J. Plast 25, 838–860 (2009)

C.L. Chow, F. Yang, H.E. Fang, Damage mechanics characterization on the fatigue behavior of a solder joint material. J. Mech. Eng. Sci. 215, 883–892 (2001)

C.L. Chow, And Wang J. crack propagation in mixed-mode ductile fracture with continuum damage mechanics. J. Mech. Eng. Sci. 203, 189–199 (1989)

D.V. Rambabu, V.R. Ranganath, U. Ramamurty, A. Chatterjee, Variable stress ratio in cumulative fatigue damage: experiments and comparison of three models. J. Mech. Eng. Sci. 224, 271–282 (2010)

K. Kyungmok, High-cycle fatigue simulation for aluminum alloy using cohesive zone law. J. Mech. Eng. Sci. 227, 683–692 (2013)

F. Shen, W. Hu, Q. Meng, A damage mechanics approach to fretting fatigue life prediction with consideration of elastic–plastic damage model and wear. Trib. Int. 82, 176–190 (2015)

K.S. Zhang, J.W. Ju, Z. Li, Y.L. Bai, W. Brocks, Micromechanics based fatigue life prediction of a polycrystalline metal applying crystal plasticity. Mech. Mater. 85, 16–37 (2015)

S. Masih, Mashayekhi1 M., and Torabian N. Identification and validation of a low cycle fatigue damage model for Al 7075-T6 alloy. J. Eng. Mater. Technol. 137, 011004 (2015)

V. Dattoma, S. Giancane, R. Nobile, F.W. Panella, Fatigue life prediction under variable loading based on a new non-linear continuum damage mechanics model. Int. J. Fatigue 28, 89–95 (2006)

Y.S. Upadhyaya, B.K. Sridhara, Fatigue life prediction: a continuum damage mechanics and fracture mechanics approach. Mater. Des. 35, 220–224 (2012)

B. Bhattacharya, B. Ellingwood, Continuum damage mechanics analysis of fatigue crack initiation. Int. J. Fatigue 20, 631–639 (1998)

B. Bhattacharya, B. Ellingwood, A new CDM-based approach to structural deterioration. Int. J. Solids Struct. 36, 1757–1779 (1999)

A. Rinaldi, P. Peralta, D. Krajcinovic, Y.C. Lai, Prediction of scatter in fatigue properties using discrete damage mechanics. Int. J. Fatigue 28, 1069–1080 (2006)

Y.C. Xiao, S. Li, Z. Gao, A continuum damage mechanic model for high cycle fatigue. Int. J. Fatigue 20, 503–508 (1998)

R. Desmorat, A. Kane, M. Seyedi, J.P. Sermage, Two scale damage model and numerical issues for thermomechanical high cycle fatigue. Eur J Mech 26, 909–935 (2007)

F. Bogard, P. Lestriez, Y.Q. Guo, Damage and rupture simulation of mechanical parts under cyclic loadings. Eng Mater Technol 132, 021003-1–021003-8 (2010)

F. Bogard, P. Lestriez, Y.Q. Guo, Numerical modeling of fatigue damage and fissure propagation under cyclic loading. Int. J. Damage Mech 17, 173–187 (2008)

M.D. Sangid, H.J. Maier, H. Sehitoglu, A physically based fatigue model for prediction of crack initiation from persistent slip bands in polycrystals. Acta Mater. 59, 328–341 (2011)

M.D. Sangid, H.J. Maier, H. Sehitoglu, The role of grain boundaries on fatigue crack initiation—an energy approach. Int. J. Plast 27, 801–821 (2011)

M.D. Sangid, H.J. Maier, H. Sehitoglu, An energy-based microstructure model to account for fatigue scatter in polycrystals. J. Mech. Phys. Solids 59, 595–609 (2011)

D.L. McDowell, F.P.E. Dunne, Microstructure-sensitive computational modeling of fatigue crack formation. Int. J. Fatigue 32, 1521–1542 (2010)

D.L. McDowell, Simulation-based strategies for microstructure-sensitive fatigue modeling. Mater Sci Eng. 468–470, 4–14 (2007)

A. Manonukul, F.P.E. Dunne, High- and low-cycle fatigue crack initiation using polycrystal plasticity. Proc. R. Soc. Lond. Ser. A 460, 1881–1903 (2004)

C.P. Przybyla, D.L. McDowell, Simulated microstructure-sensitive extreme value probabilities for high cycle fatigue of duplex Ti–6Al–4V. Int. J. Plast 27, 1871–1895 (2011)

V.V.C. Wan, D.W. MacLachlan, F.P.E. Dunne, A stored energy criterion for fatigue crack nucleation in polycrystals. Int. J. Fatigue 68, 90–102 (2014)

R. Dingreville, C.C. Battaile, L.N. Brewew, E.A. Holm, B.L. Boyce, The effect of microstructural representation on simulations of microplastic ratcheting. Int. J. Plast 26, 617–633 (2010)

F. Bridier, D.L. McDowell, P. Villechaise, J. Mendez, Crystal plasticity modeling of slip activity in Ti–6Al–4V under high cycle fatigue loading. Int. J. Plast. 25, 1066–1082 (2009)

E. Kroner, Allgemeine Kontinuumstheoreie der Versetzungen und Eigenspannnungen. Arch. Ration. Mech. Anal. 4, 273 (1959)

E.H. Lee, Elastic–plastic deformation at finite strains. J. Appl. Mech. 36, 1 (1969)

F. Roters, P. Eisenlohr, L. Hantcherli, D.D. Tjahjanto, T.R. Bieler, D. Raabe, Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite element modeling: theory, experiments, applications. Acta Mater. 58, 1152–1211 (2010)

B. Eidel, Crystal plasticity finite-element analysis versus experimental results of pyramidal indentation into (0 0 1) fcc single crystal. Acta Mater. 59, 1761–1771 (2011)

J.R. Rice, Inelastic constitutive relations for solids: an internal variable theory and its application to metal plasticity. J. Mech. Phys. Solids 19, 433–455 (1971)

D. Peirce, R.J. Asaro, A. Needleman, An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 30, 1087–1119 (1982)

D. Peirce, R.J. Asaro, A. Needleman, Material rate dependence and localized deformation in crystalline solids. Acta Metall. 31, 1951–1976 (1983)

J.W. Hutchinson, Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. Lond. A 348, 1001–1127 (1976)

R.J. Asaro, Crystal plasticity. J. Appl. Mech. 50, 921–943 (1983)

J. Lemaitre, A course on damage mechanics (Springer, Berlin, 1992)

G. Sines, Behavior of metals under complex static and alternating stresses, in Metal Fatigue, ed. by G. Sines, J.L. Waisman (McGraw-Hill Book Co., New York, 1959), p. 145

R. Stephens, A. Fatemi, R.R. Stephens, H. Fuchs, Metal Fatigue in Engineering, 2nd edn. (Wiley, New York, 2001)

Crossland B. Effect of large hydrostatic pressures on the torsional fatigue strength of an alloy steel, in Proceeding of the International Conference on fatigue of metals. Institution of Mechanical Engineers, London, 1956, pp. 138–14

K. Van Dang, Sur la résistance à la fatigue des métaux. Sci. Technol. Armement 47, 647 (1973)

T.H. Lin, Analysis of elastic and plastic strain of a fcc crystal. J. Mech. Phys. Solids 5, 143 (1957)

G. Taylor, Plastic strain in metals. J. Inst. Met. 62, 307 (1938)

Y. Xue, H. El Kadiri, M.F. Horstemeyer, J.B. Jordon, H. Weiland, Micromechanisms of multistage fatigue crack growth in a high-strength aluminum alloy. Acta Mater. 55, 1975–1984 (2007)

DREAM3D (2014) Digital Representation Environment for Analyzing Microstructure in 3D. http://www.dream3d

ABAQUS/Standard Version 6.10. User Manual (Hibbit, Karlsson and Sorensen Inc., Rhode Island, 2013)

Y. Xue, D.L. McDowell, M.F. Horstemeyer, M.H. Dale, J.B. Jordon, Microstructure-based multistage fatigue modeling of aluminum alloy 7075-T651. Eng. Fract. Mech. 74, 2810–2823 (2007)

D. Pyle, J. Lu, D. Littlewood, A. Maniatty, Effect of 3D grain structure representation in polycrystal simulations. Comput. Mech. 52, 135–150 (2013)

J.B. Jordon, M.F. Horstemeyer, K. Solanki, Y. Xue, Damage and stress state influence on the Bauschinger effect in aluminum alloys. Mech. Mater. 39, 920–931 (2007)

T. Zhao, Y. Jiang, Fatigue of 775-T651 aluminum alloy. Int. J. Fatigue 30, 834–849 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naderi, M., Amiri, M., Iyyer, N. et al. Fatigue Failure Initiation Modeling in AA7075-T651 Using Microstructure-Sensitive Continuum Damage Mechanics. J Fail. Anal. and Preven. 15, 701–710 (2015). https://doi.org/10.1007/s11668-015-0005-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-015-0005-x