Abstract

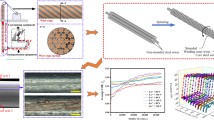

Torsion testing is used to determine the quality of steel wire used for motor tire beads in pneumatic tires. These steel wires must have good-tensile strength so that the tire bead can support the finished tire safely, and yet retain adequate ductility to deform easily around the forming wheel. The present paper highlights premature failure of bead wire which failed during torsion test. Torsion property is one of the important parameters of tire bead as it monitors both the metallurgical soundness and surface quality of a drawn wire. From the analysis, it has been concluded that probable reason for premature failure is due to strain aging (dynamic and static) caused by interstitial atoms which bounds the mobile dislocations resulting in increases yield strength and decreases bead formability. Moreover, the microstructural study indicates that failed specimen has misaligned and broken lamella of pearlite with globular cementite which creates the array of voids. These voids hinder the rotation of pearlite during torsion test thus leading to brittle fracture.

Similar content being viewed by others

References

L. Godecki, The delamination of spring wires during torsion testing. Wire Ind. 7, Part 1: 47–51, Part 2: 151–156, Part 3: 241–245, Part 4: 419–425, Part 5: 524–526 (1969)

Y.Y. Su, R.M. Shemenski, Torsion test: in-depth characterization and microscopic analysis. Wire J. 9, 128–139 (2000)

S. Vijayakar, Thermal influences on residual stresses on drawn wire—a finite element analysis. Wire J. 5, 116–119 (1997)

P. Renz, W. Steuff, R. Kopp, Possibilities of influencing residual stresses in drawn wires and bars. Wire J. 9, 64–69 (1996)

T. Tarui, J. Takahashi, H. Tashiro, N. Maruyama, S. Nishida, Microstructure control and strengthening of high-carbon steel wires. Nippon Steel Tech. Rep. 91, 56–61 (2005)

P. Watte, J.V. Humbeeck, E. Aernoudt, I. Lefever, Strain aging in heavily drawn eutectoid steel wires. Scr. Mater. 34, 89–93 (1996)

F. Springer, A. Nortmann, C. Schwink, A study of basic processes characterizing dynamic strain ageing. Phys. Stat. Sol. 170A, 63–81 (1998)

P.V. Liempt, M. Onink, A. Bodin, Modelling the influence of dynamic strain ageing on deformation behavior. Adv. Eng. Mater. 4, 225–232 (2002)

L. Godecki, Phenomena associated with the torsion deformation of steel wires. Wire Ind. 1, 719–724 (1971)

A. Robonyi, Torsion tests on wire. Wire Ind. 56, 350–352 (1989)

A.H. Cottrell, B.A. Bilby, Dislocation theory of yielding and strain ageing of iron. Proc. Phys. Soc. LXII, 49–62 (1948)

ASTM Standard D4975, Standard Test Methods for Single-Filament Tirebead Wire made from Steel (ASTM International, West Conshohocken, 2004)

W.J. Nam, C.M. Bae, Void initiation and microstructural changes during wire drawing of pearlitic steels. Mater. Sci. Eng. 203, 278 (1995)

S.K. Lee, D.C. Ko, B.M. Kim, Pass schedule of wire drawing process to prevent delamination for high strength steel cord wire. Mater. Des. 30, 2919–2927 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, S., Koli, P., Mathur, J. et al. Failure Analysis of Motor Tire Bead Wires During Torsion Test. J Fail. Anal. and Preven. 13, 684–688 (2013). https://doi.org/10.1007/s11668-013-9750-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-013-9750-x