Abstract

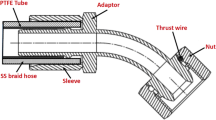

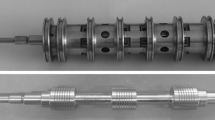

Two numbers of AISI 304L stainless steel tubes with Ø6 and Ø4 mm used in pressurisation system module of a liquid engine of a satellite launch vehicle were found to crack after the qualification level random vibration test. The module has undergone resonance survey, sinusoidal vibration, and random vibration along two different axes before the occurrence of failure. The tubes failed during third-axis random vibration test. The failed tubes were subjected to detailed metallurgical analysis to understand the reasons for failure. The location of failure in both tubes was at the cross-section change area in the nipple. Cross-section change was provided in the design to reduce the diameter of the nipple to suit to tube diameter for welding. The cross-section change in the nipple acted as stress concentration resulting in the initiation of fatigue cracks. The presence of sharp-cornered inclusions in the material helped easy crack initiation. Smaller radius and angle at the weld–parent interface resulted in additional stress concentration. The presence of striations on the fracture surface and slip bands near to the fracture edge confirm that the failure of tubes to be due to vibration induced fatigue.

Similar content being viewed by others

References

W.F. Smith, Structure and Properties of Engineering Alloys, 2nd edn. (McGraw Hill Inc., New York, 1993), pp. 312–322

M. Kutz, Handbook of Materials Selection (Wiley, New York, 2002), p. 59

J.A. Brooks, Selection of wrought austenitic stainless steel, in ASM Handbook Volume 6: Welding, Brazing and Soldering (ASM International, Materials Park, 1993)

R. Kiessling, Non-metallic Inclusions in Steel (The Metals Society, London, 1978). ISBN 0-904357-18-X

J. Cheng, R. Eriksson, P. Jönsson, Determination of macroinclusions during clean steel production. Ironmak. Steelmak. 30(1), 66–72 (2003)

W.E. Duckworth, E. Ineson, The effects of externally introduced alumina particles on the fatigue life of En24 steel. Clean Steel Iron Steel Inst. Spec. Rep. 77, 87–103 (1963)

S. Nishijima, K. Tanaka, H. Sumiyoshi, The defect size determining the fatigue limits of steels, in Advances in Fracture Research (Fracture 84), vol. 3, New Delhi, India, 4–10 Dec. 1984 (Pergamon Press Ltd., Oxford), pp. 1719–1726

A. Melander, P. Ölund, Detrimental effect of nitride and aluminium oxide inclusions on fatigue life in rotating bending of bearing steels. Mater. Sci. Technol. 15(5), 555–562 (1999)

J. Schijve, The practical and theoretical significance of small cracks. An evaluation, in Fatigue’84, Proceedings of the 2nd International Conference on Fatigue, Birmingham, 3–7 Sept. 1984, vol. 2 (EMAS, Warley, 1984), pp. 751–771

J.F. Lancaster, Metallurgy of Welding, 6th edn. (Abington Publishing, Abington, 1999), p. 240

M. Cerit, O. Kokumer, K. Genel, Stress concentration effects of undercut defect and reinforcement metal in butt welded joint. Eng. Fail. Anal. 17(2010), 571–578 (2010)

M.P. Nascimento, H.J.C. Voorwald, J.D.C. Payao Filho, Fatigue strength of tungsten inert gas-repaired weld joints in airplane critical structures. J. Mater. Process. Technol. 211(2011), 1126–1135 (2011)

J.M. Pardal, G.C. de Souza, E.C. Leao, M.R. da Silva, S.S.M. Tavares, Fatigue cracking of high pressure oil tube. Case Stud. Eng. Fail. Anal. 1(2013), 171–178 (2013)

Acknowledgments

Authors wish to thank Director, VSSC for his kind permission to publish this work. They further wish to thank ESCD, LPSC Valiamala for referring the analysis and for supplying the specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manwatkar, S.K., Kuhite, K.S., Narayana Murty, S.V.S. et al. Metallurgical Analysis of Failed AISI 304L Stainless Steel Tubes Used in Launch Vehicle Applications. Metallogr. Microstruct. Anal. 4, 497–507 (2015). https://doi.org/10.1007/s13632-015-0247-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-015-0247-8