Abstract

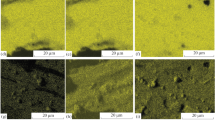

Low-pressure plasma spraying under an argon atmosphere was employed to deposit molybdenum and tungsten coatings on different metallic, ceramic, and composite substrates. Molybdenum coatings ob-tained through this technique presented a homogeneous structure with an average porosity of about 17 %. These coatings exhibited adhesion greater than 40 MPa on molybdenum and grey cast iron (FT25) substrates. No adhesion was observed on an A1N surface regardless of the preheating temperature and/or surface preparation. Adhesion on AIN-Mo (AM25) composite substrate, containing 25 % dispersed metal-lic phase by volume, showed intermediate results. Tungsten coatings exhibited porosity between 10 to 12% and a typical lamellar structure. The adhesion of tungsten coatings on molybdenum and FT25 sub-strates was around 40 MPa.

Similar content being viewed by others

References

A.A. Khan, “Elaboration and Characterization of a Ceramic-Metal Composite, Used as a Substrate for High Power X-Ray Tube Anodes,” Ph.D. dissertation, University of Limoges, 1995

P.C. Wolf and F.N. Longo, Vacuum Plasma Spray Process and Coatings, General Aspects of Thermal Spraying: Proc. Ninth Int. Therm. Spray. Conf., J.H. Zaat, Ed., Nederlands Instituut voor Lastechniek, 1980, p 187–196

K.D. Borbeck, Robotics and Manipulators for Automated Plasma Spraying and Vacuum Plasma Spraying, Proc. Tenth Int. Therm. Spray. Conf., DVS Düsseldorf, 1983, p 99–104

D.J. Varacalle, L.B. Lundberg, M.J. Jacox, J.R. Hartenstine, W.L. Riggs, H. Herman, and G.A. Bancke, Fabrication of Tungsten Coatings and Monolithics Using the Vacuum Plasma Spray Process, Surf. Coat. Technol., Vol 61,1993, p 79–85

R.W. Smith and M. Mohanty, Lightweight TiC/Ti Alloy Wear Resistant Coatings for Lightweight Materials in Aerospace Applications, Ther- mal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, 1994, p 73–77

P. Siitonen, T. Konos, and P.O. Kettunen, Corrosion Properties of Stain- less Steel Coatings Made by Different Methods of Thermal Spraying, Thermal Spray Industrial Applications, C.C. Berndtand S. Sampath, Ed., ASM International, 1994, p 105–110

C. Moreau, S. Boire-Lavigne, and R.G. Saint-Jacques, The Relation- ship between the Microstructure and Thermal Diffusivity of Plasma Sprayed Tungsten Coatings, Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, 1994, p 621–626

X.L. Jiang, R. Tiwari, F. Gitzhofer, and M.I. Boulos, Plasma Deposition of Refractory Metals, Thermal Spray Coatings: Research Design and Applications, C.C. Berndt and T.F. Beraecki, Ed., ASM Interna- tional, 1993, p 309–313

T. McKechnie, P. Krotz, Y.K. Liaw, F. Zimmerman, R. Holmes, and R.M. Poorman, VPS Forming of Refractory Metals and Ceramics for Space Furnace Containment Cartridges, Thermal Spray Coatings: Research Design and Applications, C.C. Berndt and T.F. Bernecki, Ed., ASM International, 1993, p 297–301

S. Sampath and S.F. Wayne, Plasma Sprayed M0-M02C Composites: Microstructure and Properties, Thermal Spray Coatings: Research Design and Applications, C.C. Berndt and T.F. Bernecki, Ed., ASM International, 1993, p 397–403

S. Fantassi, M. Vardelle, A. Vardelle, and P. Fauchais, Influence of the Velocity of Plasma Sprayed Particles on the Splat Formation, Thermal Spray Coatings: Research Design and Applications, C.C. Berndt and T.F. Bernecki, Ed., ASM International, 1993, p 1–6

P. LeFort and R. Queriaud, Compatibility between Molybdenum and Aluminium Nitride, J. Eur. Ceram. Soc, Vol 13,1994, p 329–333

R. Queriaud, P. LeFort, andM. Billy, The Direct Bonding between A1N Ceramics and CaO Doped Tungsten, J. Eur. Ceram. Soc, Vol 8,1991, p 319–325

P. Denoirjean-Deriu and P. LeFort, Evolution of the Secondary Phase A1ON in A1N during Its Bonding with CaO Doped Tungsten, J. Eur. Ceram. Soc, Vol 11,1993, p 359–362

A. Tronche and P. Fauchais, Hard Coatings (Cr2O3, WC-Co) Properties on Aluminium or Steel Substrates, Mater. Sci. Eng., Vol 92, 1987, p 133–144

M. Meilali, A. Grimaud, and P. Fauchais, Parameters Controlling the Sand Blasting of Substrates for Plasma Spraying, Thermal Spray In- dustrial Applications, C.C. Berndt and S. Sampath, Ed., ASM Interna- tional, 1994, p 227–232

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Khan, A.A., Labbe, J.C., Grimaud, A. et al. Molybdenum and tungsten coatings for x- ray targets obtained through the low-pressure plasma spraying process. J Therm Spray Tech 6, 228–234 (1997). https://doi.org/10.1007/s11666-997-0017-5

Issue Date:

DOI: https://doi.org/10.1007/s11666-997-0017-5