Abstract

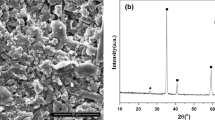

TiB2-coated graphite substrates are potential wettable cathodes for aluminum electrolysis. However, their properties must be improved to prevent the infiltration of molten aluminum into the coating, which can result in delamination of the coating. Here, a suspension plasma spray process was used to deposit TiB2 coatings (60-110 µm thick) on graphite substrate. The coating’s porosity can be controlled through the SPS deposition parameters, resulting in a porosity range between 4 and 25%. A double-layered TiB2 coating was also prepared, consisting of a denser top layer (4% porous, 40 µm thick) and a porous bottom layer (19% porous, 65 µm thick). No cracks were observed in the as-sprayed porous and double-layered coatings, in contrast to the denser single-layer (5% porosity) coating. Sessile Al drop tests were performed on TiB2 coatings to investigate their behavior in contact with molten aluminum. It was shown that the coating porosity impacts the spreading kinetics of Al drop, and all TiB2 coatings have a much better molten aluminum wettability than the graphite substrate. Moreover, after 8 h of contact with molten Al, no Al infiltration nor coating delamination was observed in the double-layered TiB2 coating, in contrast to single-layer coatings.

Similar content being viewed by others

References

Aluminium for Climate: Exploring Pathways to Decarbonize the Aluminium Industry, World Economic Forum, Community Report (2020)

M. Gautam, B. Pandey, M. Agrawal, Chapter 8 - Carbon Footprint of Aluminum Production: Emissions and Mitigation, Environmental Carbon Footprints, p 197–228 (2018). https://doi.org/10.1016/B978-0-12-812849-7.00008-8

H. Kvande and W. Haupin, Inert Anodes for Al Smelters: Energy Balances and Environmental Impact, JOM., 2001, 53, p 29-33. https://doi.org/10.1007/s11837-001-0205-6

C.E. Ransley, Refractory Carbides and Borides for Aluminum Reduction Cells, JOM., 1962, 14, p 129-135. https://doi.org/10.1007/BF03378134

C. Brown, Next Generation Vertical Electrode Cells, JOM., 2001, 53, p 39-42. https://doi.org/10.1007/s11837-001-0208-3

R.R. Patharabe, Design and Modeling of an Aluminum Smelting Process to Analyze Aluminum Smelter and Identify the Alternative Uses of Nuclear Power Small Modular Reactor, Masters Thesis, 7860, Missouri University of Science and Technology, 2017. https://scholarsmine.mst.edu/masters_theses/7860

T.T. Nguyen, V. De Nora, Aluminium Electrowinning Cell with Metal-Based Cathodes, Patent number CA2684041A1, 2008. https://patents.google.com/patent/CA2684041A1/en?oq=CA2684041A1

Y.H. Koh, S.Y. Lee, and H.E. Kim, Oxidation Behavior of Titanium Boride at Elevated Temperatures, J. Am. Ceram. Soc., 2001, 84, p 239-241. https://doi.org/10.1111/j.1151-2916.2001.tb00641.x

E. Kubiňáková, M. Benköová, P. Veteška, Ľ Bača, and J. Híveš, Surface Characterisation and Wettability of Titanium Diboride by Aluminium at Low Temperature, Adv. Appl. Ceram., 2020, 119, p 22-28. https://doi.org/10.1080/17436753.2019.1687207

D.A. Weirauch, W.J. Krafick, G. Ackart, and P.D. Ownby, The wettability of Titanium Diboride by Molten Aluminum Drops, J. Mater. Sci., 2005, 40, p 2301-2306. https://doi.org/10.1007/s10853-005-1949-0

M.S. Jensen, M. Pezzotta, Z.L. Zhang, M.-A. Einarsrud, and T. Grande, Degradation of TiB2 Ceramics in Liquid Aluminum, J. Eur. Ceram. Soc., 2008, 28, p 3155-3164. https://doi.org/10.1016/j.jeurceramsoc.2008.05.011

H. Heidari, H. Alamdari, D. Dubé, and R. Schulz, Interaction of Molten Aluminum with Porous TiB2-Based Ceramics Containing Ti–Fe Additives, J. Eur. Ceram. Soc., 2012, 32, p 937-945. https://doi.org/10.1016/j.jeurceramsoc.2011.10.053

W.A. Zdaniewski, Effect of Segregated Cr on Degradation of (Ti, Cr)B2 Exposed to Liquid Aluminum, J. Electrochem. Soc., 1986, 133, p 1777-1781. https://doi.org/10.1149/1.2109017

L. Xi, I. Kaban, R. Nowak, B. Korpała, G. Bruzda, N. Sobczak, N. Mattern, and J. Eckert, High-Temperature Wetting and Interfacial Interaction Between Liquid Al and TiB2 Ceramic, J. Mater. Sci., 2015, 50, p 2682-2690. https://doi.org/10.1007/s10853-015-8814-6

E. Yvenou, B. Davis, D. Guay, and L. Roué, Electrodeposited TiB2 on Graphite as Wettable Cathode for Al Production, J. Am. Ceram. Soc., 2021, 104, p 1247-1254. https://doi.org/10.1111/jace.17547

A.J. Caputo, W.J. Lackey, I.G. Wright, and P. Angelini, Chemical Vapor Deposition of Erosion-Resistant TiB2 Coatings, Chem. Informationsd., 1986, 17, p 2274-2280. https://doi.org/10.1002/chin.198601326

T. Takahashi and H. Kamiya, Chemical Vapor Deposition of Titanium Diboride, J. Cryst. Growth., 1974, 26, p 203-209. https://doi.org/10.1016/0022-0248(74)90247-4

B. Bakhit, J. Palisaitis, J. Thörnberg, J. Rosen, P.O.Å. Persson, L. Hultman, I. Petrov, J.E. Greene, and G. Greczynski, Improving the High-Temperature Oxidation Resistance of TiB2 Thin Films by Alloying with Al, Acta Mater., 2020, 196, p 677-689. https://doi.org/10.1016/j.actamat.2020.07.025

D. Tejero-Martin, M. Rezvani Rad, A. McDonald, and T. Hussain, Beyond Traditional Coatings: A Review on Thermal-Sprayed Functional and Smart Coatings, J. Therm. Spray Technol., 2019, 28, p 598-644. https://doi.org/10.1007/s11666-019-00857-1

M. Aghasibeig, F. Tarasi, R.S. Lima, A. Dolatabadi, and C. Moreau, A Review on Suspension Thermal Spray Patented Technology Evolution, J. Therm. Spray Technol., 2019, 28, p 1579-1605. https://doi.org/10.1007/s11666-019-00904-x

R.Z. Peng, G. Xie, Y.Q. Hou, L. Tian, and X.H. Yu, Microstructure and Property of Plasma Sprayed TiB2 Wettable Coatings on Carbon Cathodes, Adv. Mater. Res., 2014, 881-883, p 1580–1583. https://doi.org/10.4028/www.scientific.net/AMR.881-883.1580

D. Hong, Y. Niu, H. Li, X. Zhong, W. Tu, X. Zheng, and J. Sun, Comparison of Microstructure and Tribological Properties of Plasma-Sprayed TiN, TiC and TiB2 Coatings, Surf. Coat. Technol., 2019, 374, p 181-188. https://doi.org/10.1016/j.surfcoat.2019.05.071

É. Yvenou, A. Bily, F. Ben Ettouil, A. Dolatabadi, B. Davis, D. Guay, C. Moreau, and L. Roué, TiB2 Deposited on Graphite by Suspension Plasma Spray as Al Wettable Cathode, J. Therm. Spray Technol., 2021, 30, p 1535-1543. https://doi.org/10.1007/s11666-021-01222-x

F. Tarasi, M. Medraj, A. Dolatabadi, J. Oberste-Berghaus, and C. Moreau, Enhancement of Amorphous Phase Formation in Alumina–YSZ Coatings Deposited by Suspension Plasma Spray Process, Surf. Coat. Technol., 2013, 220, p 191-198. https://doi.org/10.1016/j.surfcoat.2012.10.054

Acknowledgments

The authors thank the Natural Sciences and Engineering Research Council of Canada (NSERC) through the Strategic Program (STPGP/494283-2016), Prima Québec (Grant R13-13-001), Metal7 and Kingston Process Metallurgy for supporting this work. Saeed Mohammadkhani acknowledges the support of the UNESCO Chair Materials for Energy Conversion, Saving and Storage (MATECSS) Excellence Scholarship. The authors also thank R. Schulz from Hydro-Québec's Research Institute (IREQ) for the free use of their experimental setup for sessile drop tests.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mohammadkhani, S., Bily, A., Davis, B. et al. Impact of Density on the Behavior of Suspension Plasma-Sprayed TiB2 Coatings in the Presence of Molten Aluminum. J Therm Spray Tech 31, 1499–1507 (2022). https://doi.org/10.1007/s11666-022-01370-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01370-8