Abstract

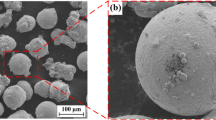

Fe50Mn30Co10Cr10 high-entropy alloys were prepared by laser cladding technology. The microstructure and phase structure of the cladding layer were analyzed. The effects of laser cladding parameters on mechanical property of the cladding layer were studied. The results show that, the Fe50Mn30Co10Cr10 high entropy alloy cladding layer is composed of FCC structure and HCP structure, BCC structure was also observed in the layer. There are fine equiaxed grains at the top of the cladding layer while columnar grains near the fusion zone. The maximum hardness of cladding layer is 292.9 HV under the laser cladding parameter of 200 W and 5 mm/s. The maximum tensile strength of the substrate with cladding layer is 692.4 MPa, and the maximum elongation is 21.3%. The fracture mode of cladding layer is ductile fracture. Adhesive wear and abrasive wear are both observed at surface of the cladding layer after wear testing. The best wear resistance is obtained at cladding parameter of 200 W, 7 mm/s with the weight loss of 0.0215g and friction coefficient of 0.6294. The results provide a certain support for the preparation process and microstructure, properties analysis of Fe50Mn30Co10Cr10 high entropy alloy.

Similar content being viewed by others

References

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122(1), p 448.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater. Sci., 2014, 61, p 1–93.

Y.P. Lu, X.Z. Gao, L. Jiang, Z.N. Chen, T.M. Wang, J.C. Jie, H.J. Kang, Y.B. Zhang, S. Guo, H.H. Ruan, Y.H. Zhao, Z.Q. Cao and T.J. Li, Directly Cast Bulk Eutectic and Near-Eutectic High Entropy Alloys with Balanced Strength and Ductility in a Wide Temperature Range, Acta Mater., 2017, 124, p 143–150.

M. L. Wang, H. Z. Cui, Y. Q. Zhao, C. M. Wang, N. Wei, Y. Zhao, X. Zhang, Q. Song, A Simple Strategy for Fabrication of an FCC-Based Complex Concentrated Alloy Coating with Hierarchical Nanoprecipitates and Enhanced Mechanical Properties, Mater. Des.,2019, 180.

M. L. Wang, Y. P. Lu, G. J. Zhang, H. Z. Cui, D. F. Xu, N. Wei, T. J. Li, A Novel High-Entropy Alloy Composite Coating with Core-Shell Structures Prepared by Plasma Cladding, Vacuum., 2021, 184.

M.L. Wang, Y.P. Lu, G.J. Zhang, H.Z. Cui, D.F. Xu, N. Wei and T.J. Li, Effect of Plasma Remelting on Microstructure and Properties of a CoCrCuNiAl0.5 High-Entropy Alloy Prepared by Spark Plasma Sintering, J. Mater. Sci., 2021, 56, p 5878–5898.

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin and J.W. Yeh, Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy High-Entropy Alloys, Acta Mater., 2011, 59(16), p 6308–6317.

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan and A. Hohenwarter, Mechanical Properties, Microstructure and Thermal Stability of a Nanocrystalline CoCrFeMnNi High-Entropy Alloy After Severe Plastic Deformation, Acta Mater., 2015, 96, p 258–268.

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen and C.T. Liu, Ductile CoCrFeNiMox High Entropy Alloys Strengthened by Hard Intermetallic Phases, Acta Mater., 2016, 116, p 332–342.

C.P. Lee, C.C. Chang, Y.Y. Chen, J.W. Yeh and H.C. Shih, Effect of the Aluminium Content of AlxCrFe1.5MnNi0.5 High-Entropy Alloys on the Corrosion Behaviour in Aqueous Environments, Corros. Sci., 2008, 50(7), p 2053–2060.

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T. Shun, C.H. Tsau and S.Y. Chang, Nanostuctures High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv Eng Mater, 2004, 6(5), p 299–303.

M.R. He, S. Wang, K. Jin, H.B. Bei, K. Yasuda, S. Matsumura, K. Higashida and I.M. Robertson, Enhanced Damage Resistance and Novel Defect Structure of CrFeCoNi Under In Situ Electron Irradiation, Scr. Mater., 2016, 125, p 5–9.

J.T. Fan, L.J. Zhang, P.F. Yu, M.D. Zhang, D.J. Liu, Z. Zhou, P. Cui, M.Z. Ma, Q. Jing, G. Li and R.P. Liu, Improved the Microstructure and Mechanical Properties of AlFeCoNi High-Entropy Alloy by Carbon Addition, Mater. Sci. Eng. A, 2018, 728, p 30–39.

T.D. Huang, C.L. Zhang, H. Jiang, Y.P. Lu and T.J. Li, Effect of Carbon Addition on the Microstructure and Mechanical Properties of CoCrFeNi High Entropy Alloy, Sci. China Technol. Sci, 2018, 61(1), p 117–123.

R.K. Nutor, M. Azeemullah, Q.P. Cao, X.D. Wang, D.X. Zhang and J.Z. Jiang, Microstructure and Properties of a Co-free Fe50Mn27Ni10Cr13 High Entropy Alloy, J. Alloys Compd., 2021, 851, p 156842.

Z.M. Li, K.G. Pradeep, Y. Deng, D. Raabe and C.C. Tasan, Metastable High-Entropy Dual-Phase Alloys Overcome the Strength-Ductility Trade-Off, Nature, 2016, 534(7606), p 227–230.

J.L. Liu, H.J. Yu, C.Z. Chen, F. Weng and J.J. Dai, Research and Development Status of Laser Cladding on Magnesium Alloys: A Review, Opt. Lasers Eng., 2017, 93, p 195–210.

L. Dubourg, D. Ursescu, F. Hlawka and A. Cornet, Laser Cladding of MMC Coatings Onaluminium Substrate: Influence of Composition and Microstructure on Mechanical Properties, Wear, 2005, 258(11–12), p 1745–1754.

F. Weng, H.J. Yu, C.Z. Chen and J.J. Dai, Microstructures and Wear Properties of Laser Cladding Co–based Composite Coatings on Ti–6Al–4V, Mater. Des., 2015, 80, p 174–181.

H.X. Liu, Q. Xu, C.Q. Wang and X.W. Zhang, Corrosion and Wear Behavior of Ni60CuMoW Coatings Fabricated by Combination of Laser Cladding and Mechanical Vibration Processing, J. Alloys Compd., 2015, 621, p 357–363.

F.Y. Shu, L. Wu, H.Y. Zhao, S.H. Sui, L. Zhou, J. Zhang, W.X. He, P. He and B.S. Xu, Microstructure and High-Temperature Wear Mechanism of Laser Cladded CoCrBFeNiSi High-Entropy Alloy Amorphous Coating, ACS Mater. Lett., 2017, 211, p 235–238.

J.D. Majumdar, R. Galun, B.L. Mordike and I. Manna, Effect of Laser Surface Meltingon Corrosion and Wear Resistance of a Commercial Magnesium Alloy, Mater. Sci. Eng. A, 2003, 361, p 119–129.

X.L. Ji, H. Duan, H. Zhang and J.J. Ma, Slurry Erosion Resistance of Laser Clad NiCoCrFeAl3 High-Entropy Alloy Coatings, Tribol. Trans., 2015, 58(6), p 1119–1123.

W. Wu, L. Jiang, H. Jiang, X.M. Pan, Z.Q. Cao, D.W. Deng, T.M. Wang and T.J. Li, Phase Evolution and Properties of Al2CrFeNiMox High-Entropy Alloys Coatings by Laser Cladding, J. Therm. Spray Technol., 2015, 24(7), p 1333–1340.

C. Ni, Y. Shi, J. Liu and G.Z. Huang, Characterization of Al0.5FeCu0.7NiCoCr High-Entropy Alloy Coating on Aluminum Alloy by Laser Cladding, Opt. Laser Technol., 2018, 105, p 257–263.

J. Y. Aguilar-Hurtado, A. Vargas-Uscategui, K. Paredes-Gil, R. Palma-Hillerns, M. J. Tobar, J. M. Amado, Boron Addition in a Non-equiatomic Fe50Mn30Co10Cr10 Alloy Manufactured by Laser Cladding: Microstructure and Wear Abrasive Resistance, Appl. Surf. Sci., 2020, 515.

Z. Wu, H. Bei, F. Otto, G.M. Pharr and E.P. George, Recovery, Recrystallization, Grain Growth and Phase Stability of a Family of FCC-Structured Multi-Component Equia-tomic Solid Solution Alloys, Intermetallics, 2014, 46, p 131–140.

G. Jin, Z. Cai, Y. Guan, X. Cui, Z. Liu, Y. Li, M. Dong and D. Zhang, High Temperature Wear Performance of Laser-Cladded FeNiCoAlCu High-Entropy Alloy Coating, Appl. Surf. Sci., 2018, 445, p 113–122.

J. B. Chen, B. Sun, Y. Y. Ge, X. L. Hu, L. H. Zhang, X. B. Liang, X. C. Zhang, Nb Doping in Laser-Cladded Fe25Co25Ni25(B0.7Si0.3)25 High Entropy Alloy Coatings: Microstructure Evolution and Wear Behavior, Surf. Coat. Technol.2020, 402.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Liu, H., Li, X., Hua, P. et al. Microstructure and Properties of Laser-cladded Fe50Mn30Co10Cr10 High Entropy Alloy Coatings. J Therm Spray Tech 31, 991–999 (2022). https://doi.org/10.1007/s11666-021-01295-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01295-8