Abstract

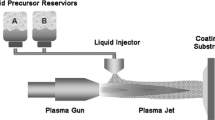

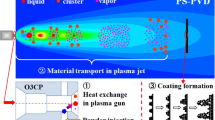

The plasma jet in the vacuum plasma spray process presents characteristics such as supersonic flow, expanded jet dimensions, and a smaller decay rate for jet velocity and temperature that are distinctly different from those of atmospheric plasma spray. In this work, a solution precursor vacuum plasma spray (SPVPS) process is described, which combines vacuum plasma spray with solution precursor as the feedstock. The deposition of superhydrophobic ceramic coatings via the SPVPS process is explored. Yb2O3 coatings are deposited by a radial injection of Yb(NO3)3 solution in the anode of an F4-VB torch operating under a pressure of 150-250 mbar. Coatings with different wetting behaviors were deposited by manipulating the process parameters of the SPVPS process. Solution precursor atmospheric plasma spray (SPAPS) is also applied to deposit superhydrophobic Yb2O3 coatings for comparison with the SPVPS process. The wetting behaviors of the coatings are characterized by water contact angle measurement, water roll-off test, and dynamic water impact test. The formation of different coating microstructures was explained via the different plasma jet characteristics, interactions of solution droplets and plasma, and droplets motions upon the impact on surface. The different wetting behaviors of coatings were correlated with the coating surface structures and topographies.

Similar content being viewed by others

References

M.F. Smith, A.C. Hall, J.D. Fleetwood, and P. Meyer, Very Low Pressure Plasma Spray—A Review of an Emerging Technology in the Thermal Spray Community, Coatings, 2011, 1(2), p 117-132

K. Von Niessen, M. Gindrat, and A. Refke, Vapor Phase Deposition Using Plasma Spray-PVD™, J. Therm. Spray Technol., 2010, 19(1–2), p 502-509

H.S. Kim, B.G. Hong, and S.Y. Moon, Thick Tungsten Layer Coating on Ferritic-Martensitic Steel without Interlayer Using a DC Vacuum Plasma Spray and a RF Low Pressure Plasma Spray Method, Thin Solid Films, 2017, 623, p 59-64

G. Mauer, M. Jarligo, S. Rezanka, A. Hospach, and R. Vaßen, Novel Opportunities for Thermal Spray by PS-PVD, Surf. Coat. Technol., 2015, 268, p 52-57

A. Hospach, G. Mauer, R. Vaßen, and D. Stöver, Characteristics of Ceramic Coatings Made by Thin Film Low Pressure Plasma Spraying (LPPS-TF), J. Therm. Spray Technol., 2012, 21(3-4), p 435-440

R. Bolot, D. Sokolov, D. Klein, and C. Coddet, Nozzle Developments for Thermal Spray at Very Low Pressure, J. Therm. Spray Technol., 2006, 15(4), p 827-833

S. Basu, E.H. Jordan, and B.M. Cetegen, Fluid Mechanics and Heat Transfer of Liquid Precursor Droplets Injected into High-Temperature Plasmas, J. Therm. Spray Technol., 2008, 17(1), p 60-72

M. Gell, E.H. Jordan, M. Teicholz, B.M. Cetegen, N.P. Padture, L. Xie, D. Chen, X. Ma, and J. Roth, Thermal Barrier Coatings Made by the Solution Precursor Plasma Spray Process, J. Therm. Spray Technol., 2008, 17(1), p 124-135

F. Rousseau, S. Awamat, D. Morvan, J. Amouroux, and R. Mevrel, Deposition of Thick Oxide Layers from Solutions in a Low Pressure Plasma Reactor, Surf. Coat. Technol., 2007, 202(4–7), p 714-718

L. Jia and F. Gitzhofer, Induction Plasma Synthesis of Nano-structured SOFCs Electrolyte Using Solution and Suspension Plasma Spraying: A Comparative Study, J. Therm. Spray Technol., 2010, 19(3), p 566-574

F. Rousseau, C. Fourmond, F. Prima, M.V. Serif, O. Lavigne, D. Morvan, and P. Chereau, Deposition of Thick and 50% Porous YpSZ Layer by Spraying Nitrate Solution in a Low Pressure Plasma Reactor, Surf. Coat. Technol., 2011, 206(7), p 1621-1627

J.L. Dorier, P. Guittienne, C. Hollenstein, M. Gindrat, and A. Refke, Mechanisms of Films and Coatings Formation from Gaseous and Liquid Precursors with Low Pressure Plasma Spray Equipment, Surf. Coat. Technol., 2009, 203(15), p 2125-2130

M. Gindrat, H.M. Höhle, K. von Niessen, P. Guittienne, D. Grange, and C. Hollenstein, Plasma Spray-CVD: A New Thermal Spray Process to Produce Thin Films from Liquid or Gaseous Precursors, J. Therm. Spray Technol., 2011, 20(4), p 882-887

M. Ma and R.M. Hill, Superhydrophobic Surfaces, Curr. Opin. Colloid Interface Sci., 2006, 11(4), p 193-202

E. Celia, T. Darmanin, E.T. de Givenchy, S. Amigoni, and F. Guittard, Recent Advances in Designing Superhydrophobic Surfaces, J. Colloid Interface Sci., 2013, 402, p 1-18

G. Azimi, R. Dhiman, H.M. Kwon, A.T. Paxson, and K.K. Varanasi, Hydrophobicity of Rare-earth Oxide Ceramics, Nat. Mater., 2013, 12(4), p 315-320

D.J. Preston, N. Miljkovic, J. Sack, R. Enright, J. Queeney, and E.N. Wang, Effect of Hydrocarbon Adsorption on the Wettability of Rare Earth Oxide Ceramics, Appl. Phys. Lett., 2014, 105(1), p 011601

S. Khan, G. Azimi, B. Yildiz, and K.K. Varanasi, Role of Surface Oxygen-to-Metal Ratio on the Wettability of Rare-Earth Oxides, Appl. Phys. Lett., 2015, 106(6), p 061601

S. Prakash, S. Ghosh, A. Patra, M. Annamalai, M.R. Motapothula, S. Sarkar, S.J. Tan, J. Zhunan, K.P. Loh, and T. Venkatesan, Intrinsic Hydrophilic Nature of Epitaxial Thin-Film of Rare-Earth Oxide Grown by Pulsed Laser Deposition, Nanoscale, 2018, 10(7), p 3356-3361

J. Tam, G. Palumbo, U. Erb, and G. Azimi, Robust Hydrophobic Rare Earth Oxide Composite Electrodeposits, Adv. Mater. Interfaces, 2017, 4(24), p 1700850

K. Nakayama, T. Hiraga, C. Zhu, E. Tsuji, Y. Aoki, and H. Habazaki, Facile Preparation of Self-Healing Superhydrophobic CeO2 Surface by Electrochemical Processes, Appl. Surf. Sci., 2017, 423, p 968-976

Y.J. Cho, H. Jang, K.S. Lee, and D.R. Kim, Direct Growth of Cerium Oxide Nanorods on Diverse Substrates for Superhydrophobicity and Corrosion Resistance, Appl. Surf. Sci., 2015, 340, p 96-101

Y. Cai, T.W. Coyle, G. Azimi, and J. Mostaghimi, Superhydrophobic Ceramic Coatings by Solution Precursor Plasma Spray, Sci. Rep., 2016, 6, p 24670

P. Xu, L. Pershin, J. Mostaghimi, and T.W. Coyle, Efficient One-Step Fabrication of Ceramic Superhydrophobic Coatings by Solution Precursor Plasma Spray, Mater. Lett., 2018, 211, p 24-27

P. Xu, T.W. Coyle, L. Pershin, and J. Mostaghimi, Superhydrophobic Ceramic Coating: Fabrication by Solution Precursor Plasma Spray and Investigation of Wetting Behavior, J. Colloid Interface Sci., 2018, 523, p 35-44

N. Zhang, F. Sun, L. Zhu, M. Planche, H. Liao, C. Dong, and C. Coddet, Measurement of Specific Enthalpy under Very Low Pressure Plasma Spray Condition, J. Therm. Spray Technol., 2012, 21(3–4), p 489-495

M. Gindrat, J.L. Dorier, C. Hollenstein, M. Loch, A. Refke, A. Salito, and G. Barbezat, Effect of Specific Operating Conditions on the Properties of LPPS Plasma Jets Expanding at Low Pressure, International Thermal Spray Conference, E. Lugscheider and C.C. Berndt, Ed., March 4-6, 2002 (Essen, Germany), DVS Deutscher Verband für Schweißen, 2002

K. Takeda, M. Ito, and S. Takeuchi, Properties of Coatings and Applications of Low Pressure Plasma Spray, Pure Appl. Chem., 1990, 62(9), p 1773-1782

H.J. Kim and S.H. Hong, Comparative Measurements on Thermal Plasma Jet Characteristics in Atmospheric and Low Pressure Plasma Sprayings, IEEE Trans. Plasma Sci., 1995, 23(5), p 852-859

Y. Zhao, P. Grant, and B. Cantor, Modelling and Experimental Analysis of Vacuum Plasma Spraying. Part I: Prediction of Initial Plasma Properties at Plasma Gun Exit, Modell. Simul. Mater. Sci. Eng., 2000, 8(4), p 497

P. Han and X. Chen, Modeling of the Supersonic Argon Plasma Jet at Low Gas Pressure Environment, Thin Solid Films, 2001, 390(1–2), p 181-185

Y. Zhao, P. Grant, and B. Cantor, Modelling and Experimental Analysis of Vacuum Plasma Spraying. Part II: Prediction of Temperatures and Velocities of Plasma Gases and Ti Particles in a Plasma Jet, Modell. Simul. Mater. Sci. Eng., 2000, 8(4), p 515

C. Crowe, R. Gore, and T. Troutt, Particle Dispersion by Coherent Structures in Free Shear Flows, Part. Sci. Technol., 1985, 3(3-4), p 149-158

E.K. Longmire and J.K. Eaton, Structure of a Particle-Laden Round Jet, J. Fluid Mech., 1992, 236, p 217-257

M.I. Boulos, P. Fauchais, and E. Pfender, Thermal Plasmas: Fundamentals and Applications, Springer, New York, 1994

A. Anwaar, L. Wei, H. Guo, and B. Zhang, Plasma-Powder Feedstock Interaction During Plasma Spray-Physical Vapor Deposition, J. Therm. Spray Technol., 2017, 26(3), p 292-301

E. Loth, Compressibility and Rarefaction Effects on Drag of a Spherical Particle, AIAA J., 2008, 46(9), p 2219-2228

S.L. Anderson and E.K. Longmire, Particle Motion in the Stagnation Zone of an Impinging Air Jet, J. Fluid Mech., 1995, 299, p 333-366

P. Huang, J. Heberlein, and E. Pfender, Particle Behavior in a Two-Fluid Turbulent Plasma Jet, Surf. Coat. Technol., 1995, 73(3), p 142-151

M. Jadidi, M. Mousavi, S. Moghtadernejad, and A. Dolatabadi, A Three-Dimensional Analysis of the Suspension Plasma Spray Impinging on a Flat Substrate, J. Therm. Spray Technol., 2015, 24(1–2), p 11-23

N. Michael and B. Bhushan, Hierarchical Roughness Makes Superhydrophobic States Stable, Microelectron. Eng., 2007, 84(3), p 382-386

A. Cassie and S. Baxter, Wettability of Porous Surfaces, Trans. Faraday Soc., 1944, 40, p 546-551

A. Vardelle, M. Vardelle, and P. Fauchais, Influence of Velocity and Surface Temperature of Alumina Particles on the Properties of Plasma Sprayed Coatings, Plasma Chem. Plasma Process., 1982, 2(3), p 255-291

R.N. Wenzel, Resistance of Solid Surfaces to Wetting by Water, Ind. Eng. Chem., 1936, 28(8), p 988-994

P. Xu, T.W. Coyle, L. Pershin, and J. Mostaghimi, Fabrication of Micro-/Nano-structured Superhydrophobic Ceramic Coating with Reversible Wettability via a Novel Solution Precursor Vacuum Plasma Spray Process, Mater. Des., 2018, 160, p 974-984

Acknowledgments

The work is supported by the China Scholarship Council, Ontario Research Fund and NSERC Discovery Grants Program [Grant No. RGPIN-2015-06377 (TWC)].

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2018 International Thermal Spray Conference, held on May 7-10, 2018, in Orlando, Florida, USA, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Xu, P., Coyle, T.W., Pershin, L. et al. Fabrication of Superhydrophobic Ceramic Coatings via Solution Precursor Plasma Spray Under Atmospheric and Low-Pressure Conditions. J Therm Spray Tech 28, 242–254 (2019). https://doi.org/10.1007/s11666-018-0814-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0814-z