Abstract

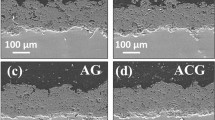

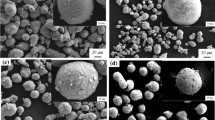

Here we report aluminum-alumina composite coatings fabricated by flame spraying for potential marine applications against both corrosion and wear. Microstructure examination suggested dense coating structures and the evenly distributed alumina splats formed hard skeleton connecting individual Al splats. The anti-corrosion and wear performance of the coatings were enhanced significantly by the addition of alumina. Failure analyses of the coatings after accelerated corrosion testing disclosed the intact alumina skeleton, which prevented further advancement of the corrosion. The results suggest that there is great potential for the cost-effective Al-Al2O3 coatings with tailorable alumina contents for application in the marine environment.

Similar content being viewed by others

References

R.E. Melchers, Long-Term Corrosion of Cast Irons and Steel in Marine and Atmospheric Environments, Corros. Sci., 2013, 68, p 186-194

W.M. Zhao, Y. Wang, C. Liu, L.X. Dong, H.H. Yu, and H. Ai, Erosion-Corrosion of Thermally Sprayed Coatings in Simulated Splash Zone, Surf. Coat. Technol., 2010, 205(7), p 2267-2272

B.R. Hou, Ocean Environment Corrosion Theory and Its Application, 1st ed., B. Peng, Ed., Science Press, 1999, p 199

Y. Bai, Q. Bai, Subsea Pipelines and Risers, 2nd ed., Elsevier Science Ltd., 2005, p 229

K.L. Money, Corrosion Testing in the Atmosphere, Metals Handbook, 9th ed., ASM International, Materials Park, 1987, p 49

D.P. Schmidt, B.A. Shaw, E. Sikora, W.W. Shaw, and L.H. Laliberte, Corrosion Protection Assessment of Sacrificial Coating Systems as a Function of Exposure Time in a Marine Environment, Prog. Org. Coat., 2006, 57(4), p 352-364

B.S. Phull and W.W. Kirk, Monitoring the Corrosivities of Atmospheric Exposure Sites, J. Prot. Coat. Linings, 1991, 8(1), p 152-162

J.A. Ellor, W.T. Young, and J. Repp, Thermally Sprayed Metal Coatings to Protect Steel Pilings: Final Report and Guide, NCHRP Report, Washington DC, 2004, p 7

M. Matsumoto, N. Okada, K. Nishihara, K. Kimoto, T. Kudo, and S. Fujimoto, Corrosion Products near the Shear Cut Edge of Steel Sheets Coated with 55 wt.% Al-Zn Alloy in a Simulated Marine Atmospheric Environment, Corros. Eng., 2010, 59(12), p 382-396

R. Selvaraj, M. Selvaraj, and S.V.K. Yer, Studies on the Evaluation of the Performance of Organic Coatings Used for the Prevention of Corrosion of Steel Rebars in Concrete Structures, Prog. Org. Coat., 2009, 64(4), p 454-459

S. Kuroda, J. Kawakita, and M. Takemoto, An 18-year Exposure Test of Thermal-Sprayed Zn, Al, and Zn-Al Coatings in Marine Environment, Corrosion, 2006, 62(7), p 635-647

J. Kawakita, S. Kuroda, T. Fukushima, and T. Kodama, Corrosion Resistance of HVOF Sprayed HastelloyC Nickel Base Alloy in Seawater, Corros. Sci., 2003, 45(12), p 2819-2835

K.S. Tan, J.A. Wharton, and R.J.K. Wood, Solid Particle Erosion-Corrosion Behaviour of a Novel HVOF Nickel Aluminium Bronze Coating for Marine Applications-Correlation Between Mass Loss and Electrochemical Measurements, Wear, 2005, 258(11-12), p 629-640

S. Armada, B.G. Tilset, M. Pilz, R. Liltvedt, H. Bratland, and N. Espallargas, Sealing HVOF Thermally Sprayed WC-CoCr Coatings by Sol-Gel Methods, J. Therm. Spray Technol., 2011, 20(4), p 918-926

Y. Wang, Y.G. Zheng, W. Ke, W.H. Sun, W.L. Hou, X.C. Chang, and J.Q. Wang, Slurry Erosion-Corrosion Behaviour of High-Velocity Oxy-Fuel (HVOF) Sprayed Fe-Based Amorphous Metallic Coatings for Marine Pump in Sand-Containing NaCl Solutions, Corros. Sci., 2011, 53(10), p 3177-3185

D. Chaliampalias, G. Vourlias, E. Pavlidou, G. Stergioudis, S. Skolianos, and K. Chrissafis, High Temperature Oxidation and Corrosion in Marine Environments of Thermal Spray Deposited Coatings, Appl. Surf. Sci., 2008, 255(5), p 3104-3111

F.S. Rogers, Thermal Spray for Commercial Shipbuilding, J. Therm. Spray Technol., 1997, 6(3), p 291-293

A.J. Speyer, Wear-Corrosion Sensing in Flowing Seawater, Ph.D. Thesis, School of Engineering Sciences, University of Southampton, November 2002

S. Kuroda, J. Kawakita, and M. Takemoto, Thermal Spray Committee, Marine Exposure Tests of Thermal Sprayed Coatings in Japan, Thermal Spray 2003: Advancing the Science and Applying the Technology. C. Moreau, B. Marple, Eds., ASM International. Materials Park, OH, 2003

R.J.K. Wood, B.G. Mellor, and M.L. Binfield, Sand Erosion Performance of Denotation Gun Applied Tungsten Carbide/Cobalt-Chromium Coatings, Wear, 1997, 211(1), p 70-83

B. Szczygieł and M. Kołodziej, Corrosion Resistance of Ni/Al2O3 Coatings in NaCl Solution, Trans. Inst. Met. Finish., 2005, 83(4), p 181-187

J.R. Scully, A. Lucente, Corrosion of Amorphous Metals. ASM Handbook. Corrosion: Materials, Vol. 13B, S.D. Cramer, B.S. Covino Jr., Eds., ASM International, Materials Park, OH, 2005, p 476-489

D. Lopez, J.P. Congote, J.R. Cano, A. Toro, and A.P. Tschiptschin, Effect of Particle Velocity and Impact Angle on the Corrosion-Erosion of AISI, 304 and AISI, 420 Stainless Steels, Wear, 2005, 259(1-6), p 118-124

A.M. Fan, J.M. Long, and Z.Y. Tao, An Investigation of the Corrosive Wear of Stainless Steels in Aqueous Slurries, Wear, 1996, 193(1), p 73-77

A. Neville, T. Hodgkiess, and J.T. Dallas, A Study of the Erosion-Corrosion Behavior of Engineering Steel for Marine Pumping Applications, Wear, 1995, 187-187(Part 2), p 497-507

L. Esposito and A. Tucci, Microstructural Dependence of Friction and Wear Behaviours in Low Purity Alumina Ceramics, Wear, 1997, 205(1-2), p 88-96

K. Poser, K.H.Z. Gahr, and J. Schneider, Development of A12O3 Based Ceramics for Dry Friction Systems, Wear, 2005, 259(1-6), p 529-538

ASTM B 117/90: Standard Test method of Sal Spray (FOG) Testing, 1990, p 19

Z.X. Tai, Y.F. Chen, Y.F. An, X.B. Yan, and Q.J. Xue, Tribological Behavior of UHMWPE Reinforced with Graphene Oxide Nanosheets, Tribol. Lett., 2012, 46(1), p 55-63

M.D. Wang and L.L. Shaw, Effects of the Powder Manufacturing Method on Microstructure and Wear Performance of Plasma Sprayed Alumina-Titania Coatings, Surf. Coat. Technol., 2007, 202(1), p 34-44

L.L. Shaw, D. Goberman, R.M. Ren, M. Gell, S. Jiang, Y. Wang, T.D. Xiao, and P.R. Strutt, The Dependency of Microstructure and Properties of Nanostructured Coatings on Plasma Spray Conditions, Surf. Coat. Technol., 2000, 130(1), p 1-8

R.M.H.P. Rodriguez, R.S.C. Paredes, S.H. Wido, and A. Calixto, Comparison of Aluminum Coatings Deposited by Flame Spray and by Electric Arc Spray, Surf. Coat. Technol., 2007, 202(1), p 172-179

R. Bhaskaran, N. Palaniswamy, N.S. Rengaswamy, and M. Jayachandran, Global Cast of Corrosion-A Historical Review, in ASM Handbook, Vol. 13B, Corrosion: Materials, ASM International, Materials Park, OH, 2005, p 621-628

I. Garcia, A. Conde, G. Langelaan, J. Fransaer, and J.P. Celis, Improved Corrosion Resistance Through Microstructural Modifications Induced by Codepositing SiC-Particles with Electrolytic Nickel, Corros. Sci., 2000, 45(6), p 1173-1189

S. Maitra and G.C. English, Mechanism of Localized Corrosion of 7075 Alloy Plate, Metall. Mater. Trans. A, 1981, 12(3), p 535-541

M.R. Barbosa, J.A. Bastos, J.J. Garcia-Jareno, and F. Vicente, Chloride Role in the Surface of Nickel Electrode, Electrochim. Acta, 1998, 44(6-7), p 957-965

M. Trueba and S.P. Trasatti, Study of Al Alloy Corrosion in Neutral NaCl by the Pitting Scan Technique, Mater. Chem. Phys., 2010, 121(3), p 523-533

Y.S. Zoo, J.W. An, D.P. Lim, and D.S. Lim, Effect of Carbon Nanotube Addition on Tribological Behavior of UHMWPE, Tribol. Lett., 2004, 16(4), p 305-309

R.G. Kelly, J.R. Scully, D.W. Shoesmith, and R.G. Buchheit, Electrochemical Techniques in Corrosion Science and Engineering, Chap. 8. Marcel-Dekker, New York, 2003, p 296-298

S.T. Aruna, V.E. Selvi, V.K.W. Grips, and K.S. Rajam, Corrosion- and Wear-Resistant Properties of Ni-Al2O3 Composite Coatings Containing Various Forms of Alumina, J. Appl. Electrochem., 2011, 41(4), p 461-468

A.R. Molla, B.V.M. Kumar, and B. Basu, Friction and Wear Mechanisms of K2O-B2O3-Al2O3-SiO2-MgO-F Glass-Ceramics, J. Eur. Ceram. Soc., 2009, 29(12), p 2481-2489

J. Park, S.H. You, D.W. Shin, and A. Ozturk, Tribological Behavior of Alumina-Added Apatite-Wollastonite Glass-Ceramics in Simulated Body Fluid, Mater. Chem. Phys., 2010, 124(1), p 113-119

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant # 31271017) and 100 Talents Program of Chinese Academy of Sciences (both to H.L.).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, J., Liu, Y., Yuan, J. et al. Al/Al2O3 Composite Coating Deposited by Flame Spraying for Marine Applications: Alumina Skeleton Enhances Anti-Corrosion and Wear Performances. J Therm Spray Tech 23, 676–683 (2014). https://doi.org/10.1007/s11666-014-0056-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0056-7