Abstract

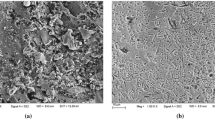

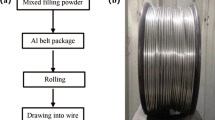

The effect of a nanoalumina sealant treatment on the long-term corrosion behavior of Al-based coatings deposited by flame spraying was investigated. X-ray diffraction and scanning electron microscopy were used to analyze the surface morphology and microstructure of the unsealed and sealed coatings. The long-term ability of the coatings to withstand corrosion was examined by electrochemical corrosion tests and salt spray corrosion experiments. The results indicate that loose pores and microcracks exist on the surface of the as-sprayed Al-based coatings. The morphologies of the surfaces of the sealed Al-based coatings are dense and flat. Electrochemical corrosion results show that the sealing treatment can effectively reduce the density of the corrosion current and improve the impedance values of all coatings. The sealing treatment prevents the corrosion medium from penetrating into the coating because defects such as pores and microcracks are filled with sealant, which can significantly improve the corrosion resistance of Al-based coatings. The corrosion current densities of the sealed coatings after salt spray corrosion tests are higher than those without salt spray corrosion experiments. With increasing salt spray corrosion time, the corrosion current densities of the sealed Al, Al-Mg and Al-Si coatings decrease, while the corrosion current density of the sealed Al-Cu coating rises gradually. The salt spray corrosion results indicate that sealed Al-based coatings are effective for preventing the long-term corrosion of components in marine environments.

Similar content being viewed by others

References

Z.Q. Wang, Z.Y. Zhou, W.C. Xu et al., Research Status and Development Trends in the Field of Marine Environment Corrosion: A New Perspective, Environ. Sci. Pollut. Res., 2021, 28, p 54403-54428.

X.K. Yang, L.W. Zhang, S.Y. Zhang et al., Properties Degradation and Atmospheric Corrosion Mechanism of 6061 Aluminum Alloy in Industrial and Marine Atmosphere Environments, Mater. Corros., 2017, 68, p 529-535.

J.C. Liu, Z.L. Li, Y.T. Li et al., Corrosion Process of D32 Steel Used for Offshore Oil Platform in Splash Zone, AntiCorros. Methods Mater., 2016, 63, p 56-64.

H. Rashid, X.Y. Dong, J. Wang et al., Plasma-Sprayed Al Alloy Coating with Enhanced Lamellar Bonding Through Novel Self-Bonding Strategy, JOM, 2020, 72(12), p 4604-4612.

B. Yu, L.F. Yang, M. Wu et al., Practical Model for Predicting Corrosion Rate of Steel Reinforcement in Concrete Structures, Constr. Build. Mater., 2014, 54, p 385-401.

V.R.S. SaBrito, I.N. Bastos, and H.R.M. Costa, Corrosion Resistance and Characterization of Metallic Coatings Deposited by Thermal Spray on Carbon Steel, Mater. Des., 2012, 41, p 282-288.

W.M. Zhao, Y. Wang, C. Liu et al., Erosion-Corrosion of Thermally Sprayed Coatings in Simulated Splash Zone, Surf. Coat. Technol., 2010, 205, p 2267-2272.

J. Kawakita, S. Kuroda, T. Fukushima et al., Corrosion Resistance of HVOF Sprayed HastelloyC Nickel Base Alloy in Seawater, Corros. Sci., 2003, 45, p 2819-2835.

S. Armada, B.G. Tilset, M. Pilz et al., Sealing HVOF Thermally Sprayed WC-CoCr Coatings by Sol-Gel Methods, J. Therm. Spray Technol., 2011, 20, p 918-926.

A. Babu, D.D. Zhurinskiy, S. Dautov et al., Structure and Electrochemical Behavior of Atmospheric Plasma Sprayed Cr3C2-NiCr Cermet Composite Coatings, Int. J. Refract. Met. Hard Mater., 2023, 111, p 106105.

D. Chaliampalias, G. Vourlias, E. Pavlidou et al., High Temperature Oxidation and Corrosion in Marine Environments of Thermal Spray Deposited Coatings, Appl. Surf. Sci., 2008, 255, p 3104-3111.

J. Sivaramapandian, M.P. Ananth, and R. Selvabharathi, Influence of Plasma Spray WCCrCNi Coating and Shot Peening on Surface Properties and Corrosion Behavior of AZ31 Mg Alloy, J. Market. Res., 2022, 19, p 3189-3200.

P.J. Zhang, Q. Liu, J. Huang et al., Phosphate Conversion of Electroplated Ni Coatings on NdFeB Magnets Improving the Anticorrosion Property, J. Alloy. Compd., 2022, 922, p 166206.

T.J. Lin, H.H. Sheu, C.Y. Lee et al., The Study of Mechanical Properties and Corrosion Behavior of the Fe-Based Amorphous Alloy Coatings Using High Velocity Oxygen Fuel Spraying, J. Alloy. Compd., 2021, 867, p 159132.

N. Cinca, C.R.C. Lima, and J.M. Guilemany, An Overview of Intermetallics Research and Application: Status of Thermal Spray Coatings, J. Market. Res., 2013, 2, p 75-86.

B. Torres, M. Campo, M. Lieblich et al., Oxy-Acetylene Flame Thermal Sprayed Coatings of Aluminium Matrix Composites Reinforced with MoSi2 Intermetallic Particles, Surf. Coat. Technol., 2013, 236, p 274-283.

F.S. Rogers, Thermal Spray for Commercial Shipbuilding, J. Therm. Spray Technol., 1997, 6, p 291-293.

P. Priputen, M. Palcut, M. Babinec et al., Correlation Between Microstructure and Corrosion Behavior of Near-Equilibrium Al-Co Alloys in Various Environments, J. Mater. Eng. Perform., 2017, 26, p 3970-3976.

J.L. Ma, J.B. Wen, Q.A. Li et al., Electrochemical Polarization and Corrosion Behavior of Al-Zn-In Based Alloy in Acidity and Alkalinity Solutions, Int. J. Hydrogen Energy, 2013, 38, p 14896-14902.

M. Palcut, P. Priputen, M. Kusy et al., Corrosion Behaviour of Al-29at%Co Alloy in Aqueous NaCl, Corros. Sci., 2013, 75, p 461-466.

A. Pardo, P. Casajus, M. Mohedano et al., Corrosion Protection of Mg/Al Alloys by Thermal Sprayed Aluminium Coatings, Appl. Surf. Sci., 2009, 255, p 6968-6977.

L.H. Chiu, C.C. Chen, and C.F. Yang, Improvement of Corrosion Properties in an Aluminum-Sprayed AZ31 Magnesium Alloy by a Post-hot Pressing and Anodizing Treatment, Surf. Coat. Technol., 2005, 191, p 181-187.

A. Forn, J.A. Picas, and M.J. Simon, Mechanical and Tribological Properties of Al-Si-Mo Plasma-Sprayed Coatings, J. Mater. Process. Technol., 2013, 143-144, p 52-57.

S.D. Zhang, J. Wu, W.B. Qi et al., Effect of Porosity Defects on the Long-Term Corrosion Behaviour of Fe-Based Amorphous Alloy Coated Mild Steel, Corros. Sci., 2016, 110, p 57-70.

S.D. Zhang, W.L. Zhang, S.G. Wang et al., Characterisation of Three-Dimensional Porosity in an Fe-Based Amorphous Coating and Its Correlation with Corrosion Behavior, Corros. Sci., 2015, 93, p 211-221.

S. Liscano, L. Gil, and M.H. Staia, Effect of Sealing Treatment on the Corrosion Resistance of Thermal-Sprayed Ceramic Coatings, Surf. Coat. Technol., 2004, 188-189, p 135-139.

C.P. Jiang, J.X. Wang, J.J. Han et al., Effect of Laser Remelting on the Microstructure and Corrosion Resistance of Plasma Sprayed Fe-Based Coating, J. Wuhan Univ. Technol. Mater. Sci. Ed., 2015, 30, p 804-807.

B.Y. Fu, D.Y. He, and L.D. Zhao, Effect of Heat Treatment on the Microstructure and Mechanical Properties of Fe-Based Amorphous Coating, J. Alloy. Compd., 2009, 480, p 422-427.

L.M. Zhang, S.D. Zhang, A.L. Ma et al., Influence of Sealing Treatment on the Corrosion Behavior of HVAF Sprayed Al-Based Amorphous/Nanocrystalline Coating, Surf. Coat. Technol., 2018, 353, p 263-273.

W.Y. Long, Y.P. Wu, W.W. Gao et al., Corrosion Resistance Behavior and Mechanism of Zn-Al-Mg-RE Coating in Seawater with SRB, Cailiao Gongcheng J. Mater. Eng., 2018, 46, p 91-97.

S.J. Sun, Z. Ma, Y.B. Liu et al., Ablation Mechanism and Properties of SiO2 Modified ZrB2-SiC Coatings Fabricated on C/C Composites Via Plasma Spraying Technology, Surf. Coat. Technol., 2020, 381, p 125132.

Q. Wang, C.S. Ramachandran, G.M. Smith et al., Sliding Wear Behavior of Air Plasma Sprayed Al2O3 Coatings Sealed with Aluminum Phosphate, Tribol. Int., 2017, 116, p 431-439.

Q.Q. Peng, M. Liu, Y.F. Huang et al., Development Mechanism and Performance of Al2O3-PF Composite Coating on Epoxy Resin Matrix Composite Surface by Supersonic Plasma Spraying, Surf. Coat. Technol., 2022, 446, p 128762.

Y. Wang, Z.Z. Xing, Q. Luo et al., Corrosion and Erosion-Corrosion Behaviour of Activated Combustion High-Velocity Air Fuel Sprayed Fe-Based Amorphous Coatings in Chloride-Containing Solutions, Corros. Sci., 2015, 98, p 339-353.

M.M. Liu, H.X. Hu, Y.G. Zheng et al., Effect of Sol-Gel Sealing Treatment Loaded with Different Cerium Salts on the Corrosion Resistance of Fe-Based Amorphous Coating, Surf. Coat. Technol., 2019, 367, p 311-326.

S.L. De Assis, S. Wolynec, and I. Costa, Corrosion Characterization of Titanium Alloys by Electrochemical Techniques, Electrochim. Acta, 2006, 51, p 1815-1819.

M.H. Gao, W.Y. Lu, B.J. Yang et al., High Corrosion and Wear Resistance of Al-Based Amorphous Metallic Coating Synthesized by HVAF Spraying, J. Alloy. Compd., 2018, 735, p 1363-1373.

Y. Wang, S.L. Jiang, Y.G. Zheng et al., Effect of Porosity Sealing Treatments on the Corrosion Resistance of High-Velocity Oxy-Fuel (HVOF)-Sprayed Fe-Based Amorphous Metallic Coatings, Surf. Coat. Technol., 2011, 206, p 1307-1318.

G.L. Ma, Y. Zhao, H.Z. Cui et al., Addition Al and/or Ti Induced Modifications of Microstructures, Mechanical Properties, and Corrosion Properties in CoCrFeNi High-Entropy Alloy Coatings, Acta Metall. Sin., 2021, 34(08), p 1087-1102.

Y.G. Zhang, Y.L. Chen, Y. Zhang et al., Initial Corrosion Behavior and Mechanism of 7B04 Aluminum Alloy Under Acid Immersion and Salt Spray Environments, Chin. J. Aeronaut., 2022, 35(1), p 277-289.

Y. Gao, J.C. Jie, P.C. Zhang et al., Corrosion Behavior of New Tin-Brass Alloys with Slightly Different Zn Content in Salt Spray Environment, Corrosion, 2015, 71(8), p 961-976.

Acknowledgment

The financial supports of the National Key Research and Development Program of China (Grant No. 2018YFA0704604), the Natural Science Foundation of Jiangsu Province (Grant No. BK20200939), the China Postdoctoral Science Foundation (Grant No. 2020M671619), Yangzhou City and Yangzhou University Cooperation Foundation (Grant Nos. YZ2022182, YZ2021153), the Postdoctoral Science Foundation of Jiangsu Province (Grant No. 2020Z450), Jiangsu Key Laboratory of Green Process Equipment (Grant No. GPE202204) and Changzhou Sci & Tech Program (Grant No. CJ20220124) are gratefully acknowledged by the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wei, X., Dai, F., Ban, A. et al. Long-Term Corrosion Behavior of Flame Sprayed Al-Based Coatings After Nano-alumina Sealing Treatment. J Therm Spray Tech 32, 2157–2169 (2023). https://doi.org/10.1007/s11666-023-01618-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01618-x