Abstract

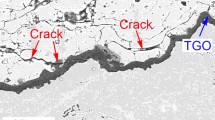

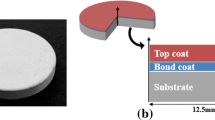

Atmospherically sprayed thermal barrier coatings (TBCs) are nowadays an essential part in modern gas turbines. However, a design integrated use of these coatings is only possible with reliable lifetime models. In this paper, a model is outlined which describes the major failure in TBCs associated with the growth of a thermally grown oxide (TGO) on the bond coat (BC). An essential part of the model is a simplified description of the crack growth as a result of thermal cycling and TGO growth. In addition, the energy release rate for the system is calculated and compared to an estimated critical energy release rate reduced by the crack growth. If both are equal, failure is assumed. The results of the modeling are compared to thermal cycling experiments partly applying a thermal gradient. BC temperatures and also microstructures of the ceramic topcoat have been varied and the influence on the cyclic life studied.

Similar content being viewed by others

References

Y.C. Zhou and T. Hashida, Thermal Fatigue Failure Induced by Delamination in Thermal Barrier Coating, Int. J. Fatigue, 2002, 24(2-4), p 407

A.M. Freborg, B.L. Ferguson, W.J. Brindley, and G.J. Petrus, Modelling Oxidation Induced Stresses in Thermal Barrier Coatings, Mater. Sci. Eng. A, 1998, 245, p 182

M.Y. He, A.G. Evans, and J.W. Hutchinson, The Ratcheting of Compressed Thermally Grown Thin Films on Ductile Substrates, Acta Mater., 2000, 48, p 2593

A.M. Karlsson and A.G. Evans, A Numerical Model For the Cyclic Instabilities of Thermally Grown Oxides in Thermal Barrier Coating Systems, Acta Mater., 2001, 49, p 1793

R. Vaßen, G. Kerkhoff, M. Ahrens, and D. Stöver, Life Time Prediction Model for Plasma-Sprayed Thermal Barrier Coatings Based on a Micromechanical Approach, Ceramic Materials and Components for Engines, J.G. Heinrich and F. Aldinger, Ed., Wiley, VCH, Weinheim, 2001, p 182.

R. Vaßen, G. Kerkhoff, and D. Stöver, Development of a Micromechanical Life Prediction Model for Plasma Sprayed Thermal Barrier Coatings, Mater. Sci. Eng. A, 2001, 303(1-2), p 100-109

G.C. Chang, W. Pucharoen, and R.A. Miller, Finite Element Thermal Stress Solutions for Thermal Barrier Coatings, Surf. Coat. Technol., 1987, 30, p 13

R.A. Miller, Oxidation-Based Model for Thermal Barrier Coating Life, J. Am. Ceram. Soc., 1984, 67, p 517

J.T. DeMasi, K.D. Sheffler, and M. Ortitz, “Thermal Barrier Coating Life Time Prediction Model Development, Phase 1 Final Report,” NASA Report, vol. CR182230, 1989.

M. Oechsner,“Ein Beitrag zur Lebensdauervorhersage von keramischen Wärmedämm-schichten,” VDI Fortschrittsberichte, 263, 2001.

D. Renusch, H. Echsler, and M. Schütze, Progress in life time modelling of APS-TBC Part I: critical strains, macro-cracking, and thermal fatigue, Mater. High Temp., 2004, 21, p 65-76

D. Renusch, H. Echsler, and M. Schütze, Progress in Life Time Modelling of APS-TBC, Part II: Critical Strains, Macro-Cracking, and Thermal Fatigue, Mater. High Temp., 2004, 21(2), p 77-86

O. Trunova, T. Beck, R. Herzog, R.W. Steinbrech, and L. Singheiser, Damage Mechanisms and Lifetime Behavior of Plasma Sprayed Thermal Barrier Coating Systems for Gas Turbines—Part I: Experiments, Surf. Coat. Technol., 2008, 202, p 5027-5032

T. Beck, R. Herzog, O. Trunova, M. Offermann, R.W. Steinbrech, and L. Singheiser, Damage Mechanisms and Lifetime Behaviour of Plasma-Sprayed Thermal Barrier Coating Systems for Gas Turbines—Part II: Modelling, Surf. Coat. Technol., 2008, 202, p 5901-5908

E.P. Busso, H.E. Evans, L. Wright, L.N. McCartney, J. Numm, and S. Osgerby, A Software Tool for Lifetime Prediction of Thermal Barrier Coating Systems, Mater. Corros., 2008, 59(7), p 556-565

M. Ahrens, R. Vaßen, and D. Stöver, Stress Distributions in Plasma-Sprayed Thermal Barrier Coatings as a Function of Interface Roughness and Oxide Scale Thickness, Surf. Coat. Technol., 2002, 161, p 26-35

F. Traeger, M. Ahrens, R. Vaßen, and D. Stöver, A Life Time Model for Ceramic Thermal Barrier Coatings, Mater. Sci. Eng., 2003, A358, p 255-265

M. Ahrens, S. Lampenscherf, R. Vaßen, and D. Stöver, Sintering and Creep Processes in Plasma-Sprayed Thermal Barrier Coatings, J. Therm. Spray Technol., 2004, 13(3), p 432-442

D. Munz and T. Fett, Ceramics Springer Series in Materials Science, Springer-Verlag, Berlin, 1999

T. Patterson, A. Leon, B. Jayaraj, J. Liu, and Y.H. Sohn, Thermal Cyclic Lifetime and Oxidation Behavior of Air Plasma Sprayed CoNiCrAlY Bond Coats for Thermal Barrier Coatings, Surf. Coat. Technol., 2008, 203, p 437-441

G.P. Cherepanov, Mechanics of Brittle Fracture, McGraw-Hill, New York, 1979, p 640

U. Bast and E. Schumann, Development of Novel Oxide Materials for TBCs, Ceram. Eng. Sci. Proc., 2002, 23(4), p 525-532

R. Vaßen, F. Traeger, and D. Stöver, New Thermal Barrier Coatings Based on Pyrochlore/YSZ Double-Layer Systems, Int. J. Appl. Ceram. Technol., 2004, 1(4), p 351-361

R. Vaßen and D. Stöver, Influence of Microstructure on the Thermal Cycling Performance of Thermal Barrier Coatings, Thermal Spray 2007: Global Coating Solutions, Beijing, PR China, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed., 14-16 May 2007, ASM International, Materials Park, OH, USA, 2007.

R. Vaßen, H. Guo, and D. Stöver, Manufacture and Properties of Segmented Thermal Barrier Coatings, Proceedings of the 29th Int. Cocoa Beach Conf. & Exposition, Cocoa Beach, Fl., D. Zhu and W.M. Kriven, Ed., 23-28 Jan, Ceram. Eng. Sci. Proc., 26(38), 2005, p 37-45.

J. Malzbender and R.W. Steinbrech, Determination of Stress-Dependent Stiffness of Plasma-Sprayed Thermal Barrier Coatings Using Depth-Sensitive Indentation, J. Mater. Res., 2003, 18(8), p 1975-1984

T. Wakui, J. Malzbender, and R.W. Steinbrech, Stress Analysis of Plasma Sprayed Thermal Barrier Coatings and Mechanical Stress, J. Therm. Spray Technol., 2004, 13(3), p 390-395

Acknowledgments

The support of Dr. Franziska Träger and especially of Dr. Jose Marques for performing Ansys calculations of the stress state and developing an analytical formula to describe the results are gratefully acknowledged. Special thanks to Dr. Jürgen Malzbender, IEF-2, Forschungszentrum Jülich GmbH, for performing the indentation tests for the determination of Young’s moduli. The authors also gratefully acknowledge the work of Mrs. Sigrid Schwartz-Lückge for carrying out scanning electron microscopy, of Mr. Karl-Heinz Rauwald, Mr. Frank Vondahlen, and Mr. Ralf Laufs for the manufacturing of the TBC systems, and of Mrs. Dr. Doris Sebold for SEM work and fruitful discussion on the oxidation test results. Also many thanks to Mrs. Nicole Hilgers for the thermal cycling work. The presented results have partly been made within a German research project MARCKO—thermal barrier coating systems, financed by the German Federal Ministry of Economics and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vaßen, R., Giesen, S. & Stöver, D. Lifetime of Plasma-Sprayed Thermal Barrier Coatings: Comparison of Numerical and Experimental Results. J Therm Spray Tech 18, 835–845 (2009). https://doi.org/10.1007/s11666-009-9389-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9389-z