Abstract

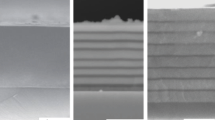

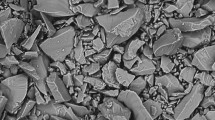

Silicon coatings were fabricated by vacuum plasma spraying technology. The morphology, composition, and microstructure of the coatings were investigated by FESEM, XRD, WDX, and TEM. The physical, mechanical, and thermal properties of the coatings were characterized. The results showed that vacuum plasma sprayed silicon coatings were compact and consisted of well-molten silicon splats. The oxidation introduced by the spraying process was limited. Small ball-like particles of size less than 1 μm existed both on the surface and inside of the coatings. The silicon coatings were made up of silicon grains with irregular shapes and different sizes of 0.5-1 μm. The longitudinal microstructure of silicon coatings exhibited typical two-layer microstructure of equi-axed nanometer grains and overlying columnar grains. The open porosity, density, and surface roughness of silicon coatings were 3.2%, 2.24 g/cm3, and 3.47 μm, respectively. And the microhardness and bonding strength of silicon coating, respectively, were 7.0 GPa and 20.6 MPa.

Similar content being viewed by others

References

W.J. Kima, S.H. Ahna, H.G. Kima, J.G. Kima, I. Ozdemirb, and Y. Tsunekawa, Corrosion Performance of Plasma-sprayed Cast Iron Coatings on Aluminum Alloy for Automotive Components, Surf. Coat. Technol., 2005, 200(1-4), p 1162-1167.

H. Chen, S. Lee, X. Zheng, and C. Ding, Evaluation of Unlubricated Wear Properties of Plasma-sprayed Nanostructured and Conventional Zirconia Coatings by SRV Tester, Wear, 2006, 260(9-10), p 1053-1060.

B. Liang and C. Ding, Thermal Shock Resistances of Nanostructured and Conventional Zirconia Coatings Deposited by Atmospheric Plasma Spraying, Surf. Coat. Technol., 2005, 197(2-3), p 185-192.

D. Matejka and B. Benko, Plasma Spraying of Metallic and Ceramic Materials, John Wiley & Sons Ltd, Czechoslovakia, 1989.

R.J. Janowiecki, M.C. Willson, and D.H. Harris, Plasma Spraying Process for Preparing Polycrystalline Solar Cells, U.S. Patent No. 4003770, 1977

M. Akani, R. Suryanarayanan, and G. Brun, Influence of Process Parameters on the Electrical Properties of Plasma-sprayed Silicon, J. Appl. Phys., 1986, 60(1), p 457-459.

R. Suryanarayanan, M. Akani, R. Gauthier, R. M. Ghaieth, and P. Pinard, Electron Beam Recrystallization of Plasma-sprayed Silicon Substrates, Appl. Phys. Lett., 1987, 51, p 259-260.

S. Sivoththaman, M. Rodot, R. Suryanarayanan, and A. Eyer, Optical Lamp Recrystallization of Plasma-sprayed Silicon Deposits on Different Substrates, Mat. Res. Bull., 1992, 27, p 425-430.

B.D. Kharas, S. Sampath, and R.J. Gambino, Anisotropic Resistivity in Plasma-sprayed Silicon Thick Films, J. Appl. Phys., 2005, 97, p 094906-1.

S. Sampath, A. Patel, A.H. Dent, R. Gambino, H. Herman, R. Greenlaw, and E. Tormey, Materials for Direct Write Electronics, MRS Bulletin, 2000, 25, p 181-184.

R.B. Bergmann and J.H. Werner, The Future of Crystalline Silicon Films on Foreign Substrates, Thin Solid Films, 2002, 403-404, p 162-169.

Z. Salhi, D. Klein, P. Gougeon, and C. Coddet, Development of Coating by Thermal Plasma Spraying under Very Low-pressure Condition < 1 mbar, Vacuum, 2005, 77(2), p 145-150.

F. Tamura, Y. Okayasu, and K. Kumagai, Fabrication of poly-crystalline silicon films using plasma spray method, Sol. Energ Mater. Sol. Cells., 1994, 34, p 263-270.

S.Y. Tan, R.J. Gambino, S. Sampath and H. Herman, Electrical properties of pressure quenched silicon by thermal spraying, Thin Solid Films, 2007, 515, p 7744-7750.

B.D. Kharas, G. Wei, S. Sampath and H. Zhang, Morphology and microstructure of thermal plasma sprayed silicon splats and coatings, Surf. Coat. Technol., 2006, 201, p 1454-1463.

Y. Niu, X. Liu and C. Ding, Phase composition and microstructure of silicon coatings deposited by air plasma spraying, Surf. Coat. Technol., 2006, 201, p 1660-1665.

C.L. Yaws, Inorganic Compounds and Elements, Hand Book of Viscosity, Gulf publishing company, Houston, 1997, p 349.

S. Kitahara and A. Hasui, A Study of the Bonding Mechanism of Sprayed Coatings, J. Vacuum Sci. Technol., 1974, 11, p 747-753.

L. Li, X.Y. Wang, G. Wei, A. Vaidya, H. Zhang, and S. Sampath, Substrate Melting During Thermal Spray Splat Quenching, Thin Solid Films, 2004, 468(1-2), p 113-119.

E. Richter, J. Piekoszewski, F. Prokert, J. Stanislawski, L. Walis, and E. Wieser, Alloying of Silicon on Ti6Al4V Using High Intensity Pulsed Plasma Beams, Vacuum, 2001, 63(4), p 523-527.

V.P. Salvi, S.V. Vidwans, A.A. Rangwala, B.M. Arora, Kuldeep, and A.K. Jain, Formation of Titanium Silicides by High Dose Ion Implantation, Nucl. Instrum. Meth. B, 1987, 28, p 242-246.

Y.R. Niu, X.Y. Liu, X.M. Zhou, and C.X. Ding, Microstructure and Properties of Silicon Coating Prepared by Air Plasma Spraying, Thermal Spray 2007: Global Coating Solutions, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed., May 14-16, 2007 (Beijing, China), ASM International, 2007, p 992-995

D. Girginoudi, A. Mitsinakis, M. Kotsani, N. Georgoulas, A. Thanailakis, A.G. Kontos, V.C. Stergiou, and Y.S. Raptis, Properties of Polycrystalline Silicon Films Obtained by Rapid Thermal Processing for Micromechanical Sensors, J. Non-Cryst. Solids, 2004, 343(1-3), p 54-60.

T. Chraska and A.H. King, Transmission Electron Microscopy Study of Rapid Solidification of Plasma Sprayed Zirconia. Part I. First Splat Solidification, Thin Solid Films, 2001, 397(1-2), p 30-39.

China Materials Engineering Canon, Chemical Industry Press, Beijing, 2006, p 513 (in Chinese)

Acknowledgments

This study was jointly supported by the National Basic Research Fund under grant 2005CB623901, Shanghai Science and Technology R&D Fund under grant 05nm05014, Innovation Fund of SICCAS under grant SCX200410, and the Foundation for the Author of National Excellent Doctoral Dissertation of PR China (FANEDD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Niu, Y., Liu, X., Zheng, X. et al. Microstructure and Properties Characterization of Silicon Coatings Prepared by Vacuum Plasma Spraying Technology. J Therm Spray Tech 18, 427–434 (2009). https://doi.org/10.1007/s11666-009-9326-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9326-1