Abstract

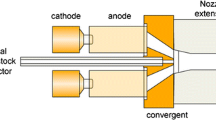

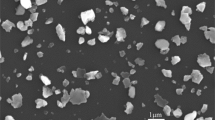

Suspension plasma spraying (SPS) is able to process sub-micrometric-sized feedstock particles and permits the deposition of layers thinner (from 5 to 50 μm) than those resulting from conventional atmospheric plasma spraying (APS). SPS consists in mechanically injecting within the plasma flow a liquid suspension of particles of average diameter varying between 0.02 and 1 μm, average values. Upon penetration within the DC plasma jet, two phenomena occur sequentially: droplet fragmentation and evaporation. Particles are then processed by the plasma flow prior their impact, spreading and solidification upon the surface to be covered. Depending upon the selection of operating parameters, among which plasma power parameters (operating mode, enthalpy, spray distance, etc.), suspension properties (particle size distribution, powder mass percentage, viscosity, etc.), and substrate characteristics (topology, temperature, etc.), different coating architectures can be manufactured, from dense to porous layers. Nevertheless, the coupling between the parameters controlling the coating microstructure and properties are not yet fully identified. The aim of this study is to further understand the influence of parameters controlling the manufacturing mechanisms of SPS alumina coatings, particularly the spray beads influence.

Similar content being viewed by others

References

R. Siegert, J.E. Döring, J.L. Marqués, R. Vaβen, D. Sebold, and D. Stöver, Denser Ceramic Coatings Obtained by the Optimization of the Suspension Plasma Spraying Technique, Thermal Spray Solutions – Advances in Technology and Application, DVS-Verlag GmbH, Düsseldorf, Germany, 2005, ISBN: 3-87155-792-7

R. Rampon, C. Filiatre, G. Bertrand (2008) Suspension plasma spraying of YPSZ coatings for SOFC: suspension atomization and injection. J. Therm. Spray Technol. 17(1):105–114

J. Jaworski, L. Pawlowski, F. Rondet, S. Kozerski, A.L. Magner (2008) Influence of suspension plasma spraying process parameter on TiO2 coatings microstructure. J. Therm. Spray Technol., 17(1):73–81

S. Bouaricha, J. Oberste-Berghaus, J.G. Legoux, C. Moreau, and T. Chraska, Suspension Plasma Spraying of Nano-Ceramics Using an Axial Injection Torch, Thermal Spray Connects: Explore its Surfacing Potential!, E. Lugscheider, Ed., DVS-Verlag GmbH, Düsseldorf, Germany, 2005, ISBN: 3-87155-793-5

R. Etchart-Salas, “Atmospheric Plasma Spraying of Submicron-Sized Solid Particles in Suspension. Experimental and Analytical Approach of Involved Phenomena in Reproducibility and Quality of Coatings,” Ph.D. Thesis, University of Limoges, France, 2007 (in French)

B.E. Gelfand (1996) Droplet breakup phenomena in flows with velocity lag. Prog. Energy Combust. Sci. 22:201–265

T. Watunabe, K. Ebihara (2003) Numerical simulation of coalescence and breakup of rising droplets. Computer and Fluids, 32:823–834

C.S. Lee, R.D. Reitz (2001) Effect of liquid properties on the breakup mechanism of high speed liquid drops. Atomization and Sprays 11:1–19

J. Fazilleau, C. Delbos, V. Rat, J.-F. Coudert, P. Fauchais, B. Pateyron (2006) Phenomena involved in suspension plasma spraying part 1: suspension injection and behavior. Plasma Chem. Plasma Proc., 26(4):371–391

P. Fauchais, M. Fukumoto, A. Vardelle, M. Vardelle (2004) Knowledge concerning splat formation : An invited review. J. Therm. Spray Technol., 13(3):337–360

M.P. Planche, J.F. Coudert, P. Fauchais (1998) Velocity measurements for arc jets produced by d.c. plasma spray torches. Plasma Chem. Plasma Proc., 18:263–283

J. Oberste-Berghaus, J.-G. Legoux, and C. Moreau, Injection Conditions and In-Flight Particle States in Suspension Plasma Spraying of Aluminia and Zirconia Nano-Ceramics, Thermal Spray Connects: Explore its Surfacing Potential!, E. Lugscheider, Ed., DVS-Verlag GmbH, Düsseldorf, Germany, 2005, ISBN: 3-87155-793-5

J.-F. Bisson, C. Moreau (2003) Effect of direct-current plasma fluctuations on in-flight particle parameters Part II. J. Thermal Spray Technol., 12:256–65

R. Etchart-Salas, V. Rat, J.-F. Coudert, and P. Fauchais, Thermal Spray 2007: Global Coating Solutions, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Eds., CD-Rom, Pub. ASM International, Materials Park, OH, USA, 2007, ISBN: 0-87170-809-4

P. Fauchais (2004) Understanding plasma spraying. J. Phys. D: Appl. Phys. 37:R86–R108

C. Delbos, “Contribution to the Understanding of Ceramic (Y-PSZ, Perovskite, etc.) or Metallic (Ni, etc.) Particles Injection by a Liquid Carrier in a Plasma Jet to Manufacture Finely-Structured Coatings for SOFC,” Ph.D. Thesis, University of Limoges, 2004 (in French)

O. Tingaud, A. Grimaud, A. Denoirjean, G. Montavon, V. Rat, J.-F. Coudert, and P. Fauchais, Effects of Operating Parameters on SPS Alumina Coatings Structures to Manufacture Functionally-Graded Layers, Surf. Coat. Technol. (in press)

Y.P. Wan, J.R. Fincke, S. Sampath, V. Prasad, H. Herman (2002) Modeling and experimental observation of evaporation from oxidizing molybdenum particles entrained in a thermal plasma jet, 2002 Int. J. Heat Mass Transfer, 45:1007–1015

I. Ahmed, T.L. Bergman (2000) Three-dimensional simulation of thermal plasma spraying of partially molten ceramic agglomerates. J. Thermal Spray Technol. 9:215–224

XI Chen (1999) Heat and momentum transfer between a thermal plasma and suspended particles for different Knudsen numbers. Thin Solid Films, 345(1):140–145

L. Xie, X. Ma, A. Ozturk, E.H. Jordan, N.P. Padture, B.M. Cetegen, D.T. Xiao, M. Gell (2004) Processing parameter effects on solution precursor plasma spray process spray patterns. Surf. Coat. Technol., 183(1):51–61

F.-I. Trifa, G. Montavon, C. Coddet (2007) Model-based expert system for design and simulation of APS coatings. J. Therm. Spray Technol. 16(3):128–139

E. Pfender (1999) Thermal plasma technology: where do we stand and where are we going?, Plasma Chem. Plasma Proc. 19:1–31

F.-I. Trifa, G. Montavon, C. Coddet (2005) On the relationships between the geometric processing parameters of APS and the Al2O3-TiO2 deposit shapes. Surf. Coat. Technol., 195:54–69

A. Haddadi, R. Hamacha, A. Grimaud, P. Fauchais, F. Nardou (1998) Residual stresses and microstructure of plasma sprayed zirconia coatings, High Temp. Mater. Processes 2(3):327–337

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2008 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Thermal Spray Crossing Borders, Proceedings of the 2008 International Thermal Spray Conference, Maastricht, The Netherlands, June 2-4, 2008, Basil R. Marple, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and Ghislain Montavon, Ed., ASM International, Materials Park, OH, 2008.

Rights and permissions

About this article

Cite this article

Tingaud, O., Grimaud, A., Denoirjean, A. et al. Suspension Plasma-Sprayed Alumina Coating Structures: Operating Parameters Versus Coating Architecture. J Therm Spray Tech 17, 662–670 (2008). https://doi.org/10.1007/s11666-008-9218-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-008-9218-9