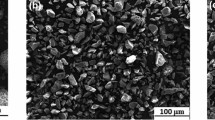

Thermal spraying is a widely used technology for industrial applications to provide coatings that improve the surface characteristics. According to the specificities of processes (APS, VPS, flame, electric arc), any kind of material can be sprayed. Among materials, ceramic coatings present several interesting aspects such as wear resistance, corrosion protection as well as thermal or electrical insulation; particularly alumina coatings which appear as the most commonly used. From all spraying processes, atmospheric plasma spraying (APS) is a rather well-established process but some others can also be used with a lower economical impact such as the flame technology. The aim of this study was to analyze the alumina coating properties according to the technology employed such as APS or wire flame spraying using the Rokide™ and the Master Jet® guns. After micrographic analyses by SEM, physical and mechanical properties were measured considering the thermal conductivity and the hardness.

Similar content being viewed by others

References

S. Sampath, H. Herman, Rapid Solidification and Microstructure Development During Plasma Spray Deposition. J. Therm. Spray Tech., 1996, 5(4), p 445-456

P. Fauchais, A. Vardelle, and B. Dussoubs, Quo vadis thermal spraying?, Proceeding in International Thermal Spray Conference, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Eds., ASM international, Materials Park, Ohio, USA, 2001, p 32

A. Kulkarni, S. Sampath, A. Goland, H. Herman, B. Dowd, Computed Microtomography Studies to Characterize Microstructure Property Correlations in Thermal Sprayed Alumina Deposits. Scipta Mater., 2000, 43, p 471-476

R. Yamasaki and J. Takeuchi, Physical Characteristics of Alumina Coating Using Atmospheric Plasma Spraying (APS) and Low Pressure Plasma Spraying (VPS), Proceeding of the ITSC Conference, Thermal Spray 2004: Advances in technology and application, A. Ohmori, Ed., May 2004 (Osaka, Japan) ASM International, Materials Park, OH, USA

A. Kulkarni, J. Gutleber, S. Sampath, A. Goland, W.B. Lindquist, H. Herman, A.J. Allen, B. Dowd, Studies of the Microstructure and Properties of Dense Ceramic Coatings Produced by High Velocity Oxygen Fuel Combustion Spraying Mater. Sci. Eng., 2004, A369, p 124-137

G. Antou, F. Hlawska, R. Bolot, G. Montavon, C. Coddet, and A. Cornet, Pore Network Architecture and Thermal Conductivity of Y-PSZ TBCs In situ Remelted During Their Deposition, Proceeding of the ITSC Conference, Thermal Spray Connects: Explore its Surface Potential, E. Lugscheider, Ed., ASM International, Materials Park, OH, USA, 2005

R. Bolot, G. Antou, G. Montavon, C. Coddet, A Two Dimensional Heat Transfer Model for Thermal Barrier Coating Average Thermal Conductivity Computation. Numer. Heat Tr. A-Appl., 2005, 47, p 875-898

R. Bolot, G. Antou, G. Montavon, and C. Coddet, Calcul numérique de la conductivité thermique des dépôts de zircone yttriée élaborés par projection thermique, Proceeding of Matériaux 2006 Conference, Dijon, France, novembre 2006

E. Litovsky, M. Shapiro, A. Shavit, Gas Pressure and Temperature Dependences of Thermal Conductivity of Porous Ceramics Materials: Part I, Refractories and Ceramics with Porosity Below 30%, J. Am. Ceram. Soc., 1992, 75(12), p 3425-3439

M. Laurent and P.L. Vuillermoz, Conductivité thermmique des solides (in french), Techniques de l’ingénieur, K420, p 1-29

L. Bianchi, P. Lucchese, A. Denoirjean, and P. Fauchais, Microstructural Investigation of Plasma Sprayed Alumina Splats, NTSC95, Proceeding of thermal spray science and technology, C.C. Berndt, Ed., ASM International, Materials Park, OH, USA, 1995, p 255-260

Acknowledgments

This study was realized with the collaboration of SNECMA. Authors gratefully thank such company as well as St Gobain (and more precisely Mr. P. Fournier) for the availability of the Rokide™ as well as the Master Jet® processes. The authors would like to express their thanks to Ms. F. Moitrier and A. Lidolff for all the works carried out during their training period. LERMPS is member of the Institut des Traitements de Surface de Franche-Comté (ITSFC, Surface treatment institute of Franche-Comté), France.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2007 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Global Coating Solutions, Proceedings of the 2007 International Thermal Spray Conference, Beijing, China, May 14-16, 2007, Basil R. Marple, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and Ghislain Montavon, Ed., ASM International, Materials Park, OH, 2007.

Rights and permissions

About this article

Cite this article

Costil, S., Verdy, C., Bolot, R. et al. On the Role of Spraying Process on Microstructural, Mechanical, and Thermal Response of Alumina Coatings. J Therm Spray Tech 16, 839–843 (2007). https://doi.org/10.1007/s11666-007-9081-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-007-9081-0