Abstract

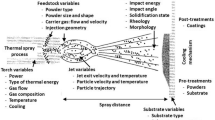

Ceramic-coated metals with enhanced properties such as chemical and environmental deterioration resistance and high thermal stability have previously found widespread uses in various industries. However, their application was limited due to weak bonding at the interfaces of dissimilar materials. To achieve the necessary interfaces and bonding qualities, a variety of procedures, primarily mechanical treatments, were used. Interface structure and composition, transition temperature, and wettability are important characteristics. In this review, extensive study has been carried out for several thermal spray methods, such as flame spray, electric arc spray, and plasma spray technology. The study explores microstructural elements of plasma-sprayed coatings, including bonding mechanisms, pore creation, oxides formation, and other important process parameters. The study emphasizes how crucial wetness is to coating development. It looks at what affects wetting, how interfacial reactions affect reactive wetting, and how important additives or reactive materials are to encouraging wetting. In conclusion, the authors suggest the next studies and technological developments in coating technologies and thermal spray procedures. The study contributes to the continuous advancement of these processes and their applications by pointing out opportunities for more research and development.

Similar content being viewed by others

References

Agarwal H, Breining WM, Sánchez-Velázquez G, Lynn DM (2022) Reactive multilayers and coatings fabricated by spray assembly: influence of polymer structure and process parameters on multiscale structure and interfacial properties. Chem Mater 34:1245–1258

Ahmed A, Mhaede M, Wollmann M, Wagner L (2015) Characteristics of sintered HA coating deposited by chemical method on AISI 316L substrate. Mater Des 76:9–17

Amado J, Montero J, Tobar M, Yáñez A (2012) Ni-based metal matrix composite functionally graded coatings. Phys Procedia 39:362–367

Andrieux J, Dezellus O, Bosselet F, Viala J (2009) Low-temperature interface reaction between titanium and the eutectic silver-copper brazing alloy. J Phase Equilib Diffus 30:40–45

Ann Gan J, Berndt CC (2015) 23 - Thermal spray forming of titanium and its alloys. In: Qian M, Froes FH (eds) Titanium powder metallurgy. Butterworth-Heinemann, Boston, pp 425–446

Armster SQ, Delplanque JP, Rein M, Lavernia EJ (2002) Thermo–fluid mechanisms controlling droplet based materials processes. Int Mater Rev 47:265–301

Arrabal R, Pardo A, Merino M, Mohedano M, Casajús P, Merino S (2010) Al/SiC thermal spray coatings for corrosion protection of Mg–Al alloys in humid and saline environments. Surf Coat Technol 204:2767–2774

Azadi Tabar M, Barzegar F, Ghazanfari MH, Mohammadi M (2019) On the applicability range of Cassie-Baxter and Wenzel equation: a numerical study. J Braz Soc Mech Sci Eng 41:1–12

Aziz SD, Chandra S (2000) Impact, recoil and splashing of molten metal droplets. Int J Heat Mass Transf 43:2841–2857

Baghal SL, Sohi MH, Amadeh A (2012) A functionally gradient nano-Ni–Co/SiC composite coating on aluminum and its tribological properties. Surf Coat Technol 206:4032–4039

Banthia S, Amid M, Sengupta S, Das S, Das K (2020) Reciprocating sliding wear of Cu, Cu–SiC functionally graded coating on electrical contact. J Mater Eng Perform 29:3930–3940

Benkreif R, Brahmia FZ, Csiha C (2021) Influence of moisture content on the contact angle and surface tension measured on birch wood surfaces. Eur J Wood Wood Prod 79:907–913

Bertrand G, Bertrand P, Roy P, Rio C, Mevrel R (2008) Low conductivity plasma sprayed thermal barrier coating using hollow psz spheres: correlation between thermophysical properties and microstructure. Surf Coat Technol 202:1994–2001

Bhusal S, Zhang C, Bustillos J, Nautiyal P, Boesl B, Agarwal A (2019) A computational approach for predicting microstructure and mechanical properties of plasma sprayed ceramic coatings from powder to bulk. Surf Coat Technol 374:1–11

Bian H, Zhou Y, Song X, Hu S, Shi B, Kang J et al (2019) Reactive wetting and interfacial characterization of ZrO2 by SnAgCu–Ti alloy. Ceram Int 45:6730–6737

Blanchi L, Grimaud A, Blein F, Lucchèse P, Fauchais P (1995) Comparison of plasma-sprayed alumina coatings by RF and DC plasma spraying. J Therm Spray Technol 4:59–66

Bocklisch F, Paczkowski G, Zimmermann S, Lampke T (2022) Integrating human cognition in cyber-physical systems: a multidimensional fuzzy pattern model with application to thermal spraying. J Manuf Syst 63:162–176

Bolelli G, Lusvarghi L, Giovanardi R (2008) A comparison between the corrosion resistances of some HVOF-sprayed metal alloy coatings. Surf Coat Technol 202:4793–4809

Brossard S, Munroe P, Tran A, Hyland M (2010a) Study of the splat-substrate interface for a NiCr coating plasma sprayed onto polished aluminum and stainless steel substrates. J Therm Spray Technol 19:24–30

Brossard S, Munroe P, Tran A, Hyland M (2010b) Study of the microstructure of NiCr splats plasma sprayed on to stainless steel substrates by TEM. Surf Coat Technol 204:1608–1615

Brossard S, Munroe PR, Tran ATT, Hyland MM (2010c) Effects of substrate roughness on splat formation for Ni–Cr particles plasma sprayed onto aluminum substrates. J Therm Spray Technol 19:1131–1141

Browning J (1992) Hypervelocity impact fusion—a technical note. J Therm Spray Technol 1:289–292

Campo M, Carboneras M, López M, Torres B, Rodrigo P, Otero E et al (2009) Corrosion resistance of thermally sprayed Al and Al/SiC coatings on Mg. Surf Coat Technol 203:3224–3230

Cedelle J, Vardelle M, Pateyron B, Fauchais P (2005) Investigation of plasma sprayed coatings formation by visualization of droplet impact and splashing on a smooth substrate. IEEE Trans Plasma Sci 33:414–415

Cedelle J, Vardelle M, Fauchais P (2006) Influence of stainless steel substrate preheating on surface topography and on millimeter-and micrometer-sized splat formation. Surf Coat Technol 201:1373–1382

Chandra S, Fauchais P (2009) Formation of solid splats during thermal spray deposition. J Therm Spray Technol 18:148–180

Chatha SS, Sidhu HS, Sidhu BS (2013) High-temperature behavior of a NiCr-coated T91 boiler steel in the platen superheater of coal-fired boiler. J Therm Spray Technol 22:838–847

Chellaganesh D, Khan MA, Jappes JW (2021) Thermal barrier coatings for high temperature applications—a short review. Mater Today Proc 45:1529–1534

Chraska T, King AH (2002) Effect of different substrate conditions upon interface with plasma sprayed zirconia—a TEM study. Surf Coat Technol 157:238–246

Ctibor P, Lechnerová R, Beneš V (2006) Quantitative analysis of pores of two types in a plasma-sprayed coating. Mater Charact 56:297–304

Cui Y, Shen J, Geng K, Hu S (2021) Fabrication of FeCoCrNiMnAl0. 5-FeCoCrNiMnAl gradient HEA coating by laser cladding technique. Surf Coat Technol 412:127077

Davis J (2001) Surface engineering for corrosion and wear resistance, ASM international and IOM communications. Maney Publishing, Materials Park (OH)

Davis JR (2004) Handbook of thermal spray technology. ASM international

de la Roche J, Alvarado-Orozco JM, Gómez PA, Cano IG, Dosta S, Toro A (2022) Hot corrosion behavior of dense CYSZ/YSZ bilayer coatings deposited by atmospheric plasma spray in Na2SO4+ V2O5 molten salts. Surf Coat Technol 432:128066

Deng C, Kim H, Ki H (2019) Fabrication of functionally-graded yttria-stabilized zirconia coatings by 355 nm picosecond dual-beam pulsed laser deposition. Compos B Eng 160:498–504

Deng Z, Liu D, Xiong Y, Zhu X, Mi H, Liu J et al (2021) Laser cladding preparation of HA-Ag gradient bioactive ceramic coating: a feasibility study. Surf Coat Technol 427:127848

Devincent SM, Michal GM (1993) Reaction layer formation at the graphite/copper-chromium alloy interface. Metall Trans A 24:53–60

Dezellus O, Eustathopoulos N (2010) Fundamental issues of reactive wetting by liquid metals. J Mater Sci 45:4256–4264

Dhiman R, Chandra S (2005) Freezing-induced splashing during impact of molten metal droplets with high Weber numbers. Int J Heat Mass Transf 48:5625–5638

Dhiman R, McDonald AG, Chandra S (2007) Predicting splat morphology in a thermal spray process. Surf Coat Technol 201:7789–7801

Donaldson L (2021) New optical coating increases the lifetime of photovoltaic cells. Elsevier

Dongmian Z, Xiaowei X (2020) Ceramics coated metallic materials: methods, properties and applications. In: Mohsen M (ed) Advanced ceramic materials. Rijeka, IntechOpen

Eustathopoulos N, Voytovych R (2016) The role of reactivity in wetting by liquid metals: a review. J Mater Sci 51:425–437

Fanicchia F, Maeder X, Ast J, Taylor A, Guo Y, Polyakov M et al (2018) Residual stress and adhesion of thermal spray coatings: microscopic view by solidification and crystallisation analysis in the epitaxial CoNiCrAlY single splat. Mater Des 153:36–46

Fantozzi D, Matikainen V, Uusitalo M, Koivuluoto H, Vuoristo P (2017) Chlorine-induced high temperature corrosion of Inconel 625 sprayed coatings deposited with different thermal spray techniques. Surf Coat Technol 318:233–243

Fathi R, Ma A, Saleh B, Xu Q, Jiang J (2020) Investigation on mechanical properties and wear performance of functionally graded AZ91-SiCp composites via centrifugal casting. Mater Today Commun 24:101169

Fauchais P (2004) Understanding plasma spraying. J Phys D Appl Phys 37:R86

Fauchais P, Vardelle A, Vardelle M, Fukumoto M (2004) Knowledge concerning splat formation: an invited review. J Therm Spray Technol 13:337–360

Fauchais P, Montavon G, Bertrand G (2010) From powders to thermally sprayed coatings. J Therm Spray Technol 19:56–80

Fauchais PL, Heberlein JV, Boulos MI (2014) Industrial applications of thermal spraying technology. Thermal spray fundamentals. Springer, pp 1401–1566

Fujii H, Nakae H (1996) Equilibrium contact angle in the magnesium oxide/aluminium system. Acta Mater 44:3567–3573

Fujimoto H, Shiotani Y, Tong AY, Hama T, Takuda H (2007) Three-dimensional numerical analysis of the deformation behavior of droplets impinging onto a solid substrate. Int J Multiph Flow 33:317–332

Fukumoto M, Huang Y (1999) Flattening mechanism in thermal sprayed nickel particle impinging on flat substrate surface. J Therm Spray Technol 8:427–432

Fukumoto M, Ohgitani I, Yasui T (2004) Effect of substrate surface change on flattening behaviour of thermal sprayed particles. Mater Trans 45:1869–1873

Fukumoto M, Yamaguchi T, Yamada M, Yasui T (2007) Splash splat to disk splat transition behavior in plasma-sprayed metallic materials. J Therm Spray Technol 16:905–912

Gadow R, Floristán M (2015) Manufacturing engineering in thermal spraying by advanced robot systems and process kinematics. Future development of thermal spray coatings. Elsevier, pp 259–280

Galedari SA, Mahdavi A, Azarmi F, Huang Y, McDonald A (2019) A comprehensive review of corrosion resistance of thermally-sprayed and thermally-diffused protective coatings on steel structures. J Therm Spray Technol 28:645–677

Garcia E, Miranzo P, Soltani R, Coyle TW (2008) Microstructure and thermal behavior of thermal barrier coatings. J Therm Spray Technol 17:478–485

Ghadami F, Aghdam ASR, Ghadami S (2020) Preparation, characterization and oxidation behavior of CeO2-gradient NiCrAlY coatings applied by HVOF thermal spraying process. Ceram Int 46:20500–20509

Ghanavati R, Naffakh-Moosavy H, Moradi M (2021) Additive manufacturing of thin-walled SS316L-IN718 functionally graded materials by direct laser metal deposition. J Market Res 15:2673–2685

Gildersleeve EJ, Vaßen R (2023) Thermally sprayed functional coatings and multilayers: a selection of historical applications and potential pathways for future innovation. J Therm Spray Technol 32:778–817

Goutier S, Vardelle M, Fauchais P (2013) Comparison between metallic and ceramic splats: influence of viscosity and kinetic energy on the particle flattening. Surf Coat Technol 235:657–668

Grammes T, Emmerich T, Aktaa J (2021) W/EUROFER functionally graded coatings for plasma facing components: technology transfer to industry and upscaling. Fusion Eng Des 173:112940

Grimm M, Drehmann R, Lampke T, Conze S, Berger L-M (2021) Microstructure of atmospheric plasma sprayed (Al, Cr) 2O3–TiO2 coatings from blends. In ITSC2021, pp 758–764

Harun W, Asri R, Alias J, Zulkifli F, Kadirgama K, Ghani S et al (2018) A comprehensive review of hydroxyapatite-based coatings adhesion on metallic biomaterials. Ceram Int 44:1250–1268

Heichal Y, Chandra S (2005) Predicting thermal contact resistance between molten metal droplets and a solid surface. J Heat Transf 127:1269–1275

Herman H, Sampath S, McCune R (2000) Thermal spray: current status and future trends. MRS Bull 25:17–25

Hu X, Li F, Shi D, Xie Y, Li Z, Yin F (2020) A design of self-generated Ti–Al–Si gradient coatings on Ti–6Al–4V alloy based on silicon concentration gradient. J Alloy Compd 830:154670

Hussain T, Dudziak T, Simms N, Nicholls J (2013) Fireside corrosion behavior of HVOF and plasma-sprayed coatings in advanced coal/biomass co-fired power plants. J Therm Spray Technol 22:797–807

Ikeuchi D, Vargas-Uscategui A, Wu X, King PC (2019) Neural network modelling of track profile in cold spray additive manufacturing. Materials 12:2827

Ismail MF, Islam MA, Khorshidi B, Sadrzadeh M (2021) Prediction of surface charge properties on the basis of contact angle titration models. Mater Chem Phys 258:123933

Jesuraj SA, Kuppusami P, Dharini T, Panda P, Devapal D (2018) Effect of substrate temperature on microstructure and nanomechanical properties of Gd2Zr2O7 coatings prepared by EB-PVD technique. Ceram Int 44:18164–18172

Jia M, Chen F, Wu Y, Xu L, Shen Q, Jiang N et al (2022) Microstructure and shear fracture behavior of Mo/AlN/Mo symmetrical compositionally graded materials. Mater Sci Eng, A 834:142591

Jiang X, Wan Y, Herman H, Sampath S (2001) Role of condensates and adsorbates on substrate surface on fragmentation of impinging molten droplets during thermal spray. Thin Solid Films 385:132–141

Jones H (1971) Cooling, freezing and substrate impact of droplets formed by rotary atomization. J Phys D Appl Phys 4:1657–1660

Kadam NR, Karthikeyan G, Kulkarni DM (2019) Microstructure and mechanical properties of atmospheric plasma sprayed 8YSZ thermal barrier coatings. Advances in micro and nano manufacturing and surface engineering. singapore, pp 437–446

Kadam NR, Karthikeyan G, Kulkarni DM (2020) Effect of substrate rotation on the microstructure of 8YSZ thermal barrier coatings by EB-PVD. Mater Today Proc 28:678–683

Kadam NR, Karthikeyan G, Kulkarni DM (2022a) The effect of spray angle on the microstructural and mechanical properties of plasma sprayed8YSZ thermal barrier coatings. J Micromanuf 52(2):181–192

Kadam NR, Karthikeyan G, Jagtap PM, Kulkarni DM (2022b) An atmospheric plasma spray and electron beam-physical vapour deposition for thermal barrier coatings: a review. Aust J Mech Eng. https://doi.org/10.1080/14484846.2022.2030088

Karim AM, Rothstein JP, Kavehpour HP (2018) Experimental study of dynamic contact angles on rough hydrophobic surfaces. J Colloid Interface Sci 513:658–665

Kiilakoski J, Puranen J, Heinonen E, Koivuluoto H, Vuoristo P (2019) Characterization of powder-precursor HVOF-Sprayed Al2O3-YSZ/ZrO2 coatings. J Therm Spray Technol 28:98–107

Klinkov S, Kosarev V (2006) Measurements of cold spray deposition efficiency. J Therm Spray Technol 15:364–371

Korobov Y, Nevezhin S, Filippov M, Makarov A, Malygina I, Fantozzi D et al. (2016) Study of high velocity arc sprayed heat resistant coatings from FeCrAlBY cored wire. In Proceedings of the international thermal spray conference, pp 852–856

Kozlova O, Braccini M, Voytovych R, Eustathopoulos N, Martinetti P, Devismes M-F (2010) Brazing copper to alumina using reactive CuAgTi alloys. Acta Mater 58:1252–1260

Kozlova O, Voytovych R, Eustathopoulos N (2011) Initial stages of wetting of alumina by reactive CuAgTi alloys. Scr Mater 65:13–16

Kuanr SK, Vinothkumar G, Babu KS (2018) Substrate temperature dependent structural orientation of EBPVD deposited NiO films and its influence on optical, electrical property. Mater Sci Semicond Process 75:26–30

Kumar G, Prabhu KN (2007) Review of non-reactive and reactive wetting of liquids on surfaces. Adv Coll Interface Sci 133:61–89

Kyhl L, Balog R, Cassidy A, Jørgensen J, Grubisic-Čabo A, Trotochaud L et al (2018) Enhancing graphene protective coatings by hydrogen-induced chemical bond formation. ACS Appl Nano Mater 1:4509–4515

Łatka L, Pawłowski L, Winnicki M, Sokołowski P, Małachowska A, Kozerski S (2020) Review of functionally graded thermal sprayed coatings. Appl Sci 10:5153

Li J-G (1994) Wetting of ceramic materials by liquid silicon, aluminium and metallic melts containing titanium and other reactive elements: a review. Ceram Int 20:391–412

Li C-J, Li J-L (2004a) Evaporated-gas-induced splashing model for splat formation during plasma spraying. Surf Coat Technol 184:13–23

Li C-J, Li J-L (2004b) Transient contact pressure during flattening of thermal spray droplet and its effect on splat formation. J Therm Spray Technol 13:229–238

Li C-J, Liao H-L, Gougeon P, Montavon G, Coddet C (2005) Experimental determination of the relationship between flattening degree and Reynolds number for spray molten droplets. Surf Coat Technol 191:375–383

Li C-J, Yang G-J, Li C-X (2013) Development of particle interface bonding in thermal spray coatings: a review. J Therm Spray Technol 22:192–206

Li C-J, Luo X-T, Yao S-W, Li G-R, Li C-X, Yang G-J (2022) The bonding formation during thermal spraying of ceramic coatings: a review. J Therm Spray Technol 31:780–817

Liang P, Zeng J, Yang X, Zhang H, Dong S, Jiang J et al (2019) Duplex and functionally graded Al@ NiCr/8YSZ thermal barrier coatings on aluminum substrates. J Alloy Compd 790:928–940

Lima RS, Marple BR (2007) Thermal spray coatings engineered from nanostructured ceramic agglomerated powders for structural, thermal barrier and biomedical applications: a review. J Therm Spray Technol 16:40–63

Liu G, Muolo M, Valenza F, Passerone A (2010) Survey on wetting of SiC by molten metals. Ceram Int 36:1177–1188

López A, Proy M, Utrilla V, Otero E, Rams J (2014) High-temperature corrosion behavior of Ni–50Cr coating deposited by high velocity oxygen–fuel technique on low alloy ferritic steel. Mater Des 59:94–102

Madejski J (1976) Solidification of droplets on a cold surface. Int J Heat Mass Transf 19:1009–1013

Mantry S, Sahoo R, Jha BB, Mishra BK, Chakraborty M (2014) Tribo-performance of plasma-sprayed nanostructured yttria-stabilized zirconia coatings using Taguchi’s experimental design. Proc Inst Mech Eng Part J J Eng Tribol 228:872–880

McDonald A, Moreau C, Chandra S (2007a) Thermal contact resistance between plasma-sprayed particles and flat surfaces. Int J Heat Mass Transf 50:1737–1749

McDonald A, Moreau C, Chandra S (2007b) Effect of substrate oxidation on spreading of plasma-sprayed nickel on stainless steel. Surf Coat Technol 202:23–33

McPherson R, Shafer B (1982) Interlamellar contact within plasma-sprayed coatings. Thin Solid Films 97:201–204

Meißner TM, Montero X, Fähsing D, Galetz MC (2020) Cr diffusion coatings on a ferritic-martensitic steel for corrosion protection in KCl-rich biomass co-firing environments. Corros Sci 164:108343

Mihm S, Duda T, Gruner H, Thomas G, Dzur B (2012) Method and process development of advanced atmospheric plasma spraying for thermal barrier coatings. J Therm Spray Technol 21:400–408

Milanti A, Matikainen V, Koivuluoto H, Bolelli G, Lusvarghi L, Vuoristo P (2015) Effect of spraying parameters on the microstructural and corrosion properties of HVAF-sprayed Fe–Cr–Ni–B–C coatings. Surf Coat Technol 277:81–90

Miller RA (1987) Current status of thermal barrier coatings—an overview. Surf Coat Technol 30:1–11

Moreau C, Gougeon P, Lamontagne M (1995) Influence of substrate preparation on the flattening and cooling of plasma-sprayed particles. J Therm Spray Technol 4:25–33

Morks M, Tsunekawa Y, Okumiva M, Shoeib M (2002) Splat morphology and microstructure of plasma sprayed cast iron with different preheat substrate temperatures. J Therm Spray Technol 11:226–232

Moskal G, Migas D, Osadnik M, Wrona A (2019) Characterization of the gradient (Mo, Re) Si2/Mo-Re coatings deposited in the hybrid process. J Therm Spray Technol 28:1532–1553

Mundo C, Sommerfeld M, Tropea C (1995) Droplet-wall collisions: experimental studies of the deformation and breakup process. Int J Multiph Flow 21:151–173

Murray JW, Leva A, Joshi S, Hussain T (2018) Microstructure and wear behaviour of powder and suspension hybrid Al2O3–YSZ coatings. Ceram Int 44:8498–8504

Myoung S-W, Kim J-H, Lee W-R, Jung Y-G, Lee K-S, Paik U (2010) Microstructure design and mechanical properties of thermal barrier coatings with layered top and bond coats. Surf Coat Technol 205:1229–1235

Naidich Y (2005) About liquid metal/ceramic interface interaction mechanism and mode of a new intermediate compound formation. Curr Opin Solid State Mater Sci 9:161–166

Nicholas M, Valentine T, Waite M (1980) The wetting of alumina by copper alloyed with titanium and other elements. J Mater Sci 15:2197–2206

Nosonovsky M (2007) On the range of applicability of the Wenzel and Cassie equations. Langmuir 23:9919–9920

Odhiambo JG, Li W, Zhao Y, Li C (2019) Porosity and its significance in plasma-sprayed coatings. Coatings 9:460

Oksa M, Metsäjoki J, Kärki J (2015) Thermal spray coatings for high-temperature corrosion protection in biomass co-fired boilers. J Therm Spray Technol 24:194–205

Pandey SM, Murtaza Q, Walia R (2017) Study of dry wear behavior and morphological characteristic of 60% Mo-20% NiCr-10% CrC-10% Mo+ Fe based alloy coating by atmospheric plasma spray technique. Adv Mater Process Technol 3:393–406

Pandey SM, Murtaza Q, Walia R (2018) Effect of NiCr on dry sliding wear of high carbon iron-molybdenum composite plasma spray coating. Int J Precis Technol 8:1–23

Parmar H, Tucci F, Carlone P, Sudarshan T (2022) Metallisation of polymers and polymer matrix composites by cold spray: state of the art and research perspectives. Int Mater Rev 67:385–409

Peng Y, Zhang C, Zhou H, Liu L (2013) On the bonding strength in thermally sprayed Fe-based amorphous coatings. Surf Coat Technol 218:17–22

Petrova V, Schmauder S (2020) A theoretical model for the study of thermal fracture of functionally graded thermal barrier coatings with a system of edge and internal cracks. Theor Appl Fract Mech 108:102605

Protsenko P, Terlain A, Traskine V, Eustathopoulos N (2001) The role of intermetallics in wetting in metallic systems. Scr Mater 45:1439–1445

Rana N, Mahapatra MM, Jayaganthan R, Prakash S (2015) High-temperature oxidation and hot corrosion studies on NiCrAlY coatings deposited by flame-spray technique. J Therm Spray Technol 24:769–777

Rao H, Jayasekara I, Dutta B, Maurice D (2020) Segregation phenomena during deposition of functionally graded zirconia-based ceramics with Stellite 21 on a steel substrate. Surf Coat Technol 383:125270

Rath PC, Besra L, Singh BP, Bhattacharjee S (2012) Titania/hydroxyapatite bi-layer coating on Ti metal by electrophoretic deposition: characterization and corrosion studies. Ceram Int 38:3209–3216

Rezakhani D (2007) Corrosion behaviours of several thermal spray coatings used on boiler tubes at elevated temperatures. Anti-Corros Methods Mater 54:237–243. https://doi.org/10.1108/00035590710762384

Rousseau F, Guyon C, Morvan D, Bacos MP, Lavigne O, Rio C et al (2021) Low power plasma spray assisted thermal barrier coating repair without the plugging of cooling holes. Surf Coat Technol 412:127050

Sadeghi E, Markocsan N, Joshi S (2019) Advances in corrosion-resistant thermal spray coatings for renewable energy power plants. Part I: effect of composition and microstructure. J Therm Spray Technol 28:1749–1788

Sadeghimeresht E (2018) Ni-based coatings for high temperature corrosion protection. University West

Sadeghimeresht E, Markocsan N, Nylén P (2016) A comparative study on Ni-based coatings prepared by HVAF, HVOF, and APS methods for corrosion protection applications. J Therm Spray Technol 25:1604–1616

Saleh B, Ahmed M (2021) Wear characteristics of functionally graded tubes reinforced with silicon carbide and alumina: a comparative study. Trans Nanjing Univ Aeronaut Astronaut 38:76–83

Saleh B, Jiang J, Fathi R, Al-hababi T, Xu Q, Wang L et al (2020) 30 Years of functionally graded materials: an overview of manufacturing methods, applications and future challenges. Compos B Eng 201:108376

Sarc R, Curtis A, Kandlbauer L, Khodier K, Lorber KE, Pomberger R (2019) Digitalisation and intelligent robotics in value chain of circular economy oriented waste management—a review. Waste Manag 95:476–492

Schulz U, Rätzer-Scheibe H-J, Saruhan B, Renteria AF (2007) Thermal conductivity issues of EB-PVD thermal barrier coatings. Mater Werkst 38:659–666

Shi M, Xue Z, Zhang Z, Ji X, Byon E, Zhang S (2020) Effect of spraying powder characteristics on mechanical and thermal shock properties of plasma-sprayed YSZ thermal barrier coating. Surf Coat Technol 395:125913

Shin K, Acri T, Geary S, Salem AK (2017) Biomimetic mineralization of biomaterials using simulated body fluids for bone tissue engineering and regenerative medicine. Tissue Eng Part A 23:1169–1180

Šikalo Š, Tropea C, Ganić E (2005) Dynamic wetting angle of a spreading droplet. Exp Thermal Fluid Sci 29:795–802

Singh H, Puri D, Prakash S (2005) High temperature oxidation behaviour of plasma sprayed NiCrAlY coatings on Ni-based superalloys in air. Trans Indian Inst Met 59:215

Singh A, Sharma V, Mittal S, Pandey G, Mudgal D, Gupta P (2018) An overview of problems and solutions for components subjected to fireside of boilers. Int J Ind Chem 9:1–15

Singh S, Berndt CC, Singh Raman RK, Singh H, Ang ASM (2023) Applications and developments of thermal spray coatings for the iron and steel industry. Materials 16:516

Song B, Pala Z, Voisey K, Hussain T (2017) Gas and liquid-fuelled HVOF spraying of Ni50Cr coating: microstructure and high temperature oxidation. Surf Coat Technol 318:224–232

Sopronyi M, Nita C, Le Meins J-M, Vidal L, Jipa F, Axente E et al (2021) Laser-assisted synthesis of carbon coatings with cobalt oxide nanoparticles embedded in gradient of composition and sizes. Surf Coat Technol 419:127301

Stathopoulos V, Sadykov V, Pavlova S, Bespalko Y, Fedorova Y, Bobrova L et al (2016) Design of functionally graded multilayer thermal barrier coatings for gas turbine application. Surf Coat Technol 295:20–28

Sun J, Fu Q-G, Li T, Zhang G-P, Yuan R-M (2019) Oxidation behavior of thermally sprayed Mo–Si based composite: effect of metastable phase, porosity and residual stress. J Alloy Compd 776:712–721

Taleghani P, Valefi Z, Ehsani N (2021) Evaluation of oxidation and thermal insulation capability of nanostructured La2 (Zr0· 7Ce0. 3) 2O7/YSZ functionally graded coatings. Ceram Int 47:8915–8929

Talib R, Saad S, Toff M, Hashim H (2003) Thermal spray coating technology: a review. Solid State Sci Technol 11:109–117

Tanaka Y, Fukumoto M (1999) Investigation of dominating factors on flattening behavior of plasma sprayed ceramic particles. Surf Coat Technol 120:124–130

Tscheliessnig R, Zörnig M, Herzig EM, Lückerath K, Altrichter J, Kemter K et al (2012) Nano-coating protects biofunctional materials. Mater Today 15:394–404

Tsukamoto H (2010) Design against fracture of functionally graded thermal barrier coatings using transformation toughening. Mater Sci Eng A 527:3217–3226

Tyagi A, Walia R, Murtaza Q, Pandey SM, Tyagi PK, Bajaj B (2019a) A critical review of diamond like carbon coating for wear resistance applications. Int J Refract Metal Hard Mater 78:107–122

Tyagi A, Pandey SM, Walia R, Murtaza Q (2019b) Characterization and parametric optimization of tribological properties of Mo blend composite coating. Mater Res Express 6:086428

Uusitalo M, Vuoristo P, Mäntylä T (2002) High temperature corrosion of coatings and boiler steels in reducing chlorine-containing atmosphere. Surf Coat Technol 161:275–285

Valette C, Devismes M-F, Voytovych R, Eustathopoulos N (2005) Interfacial reactions in alumina/CuAgTi braze/CuNi system. Scr Mater 52:1–6

Vignesh S, Shanmugam K, Balasubramanian V, Sridhar K (2017) Identifying the optimal HVOF spray parameters to attain minimum porosity and maximum hardness in iron based amorphous metallic coatings. Def Technol 13:101–110

Viscusi A, Astarita A, Gatta RD, Rubino F (2019) A perspective review on the bonding mechanisms in cold gas dynamic spray. Surf Eng 35:743–771

Viswanathan V, Katiyar NK, Goel G, Matthews A, Goel S (2021) Role of thermal spray in combating climate change. Emerg Mater 4:1–15

Voytovych R, Robaut F, Eustathopoulos N (2006) The relation between wetting and interfacial chemistry in the CuAgTi/alumina system. Acta Mater 54:2205–2214

Wagner N (2021) Effect of process parameters on twin wire arc sprayed steel coatings. J Mater Eng Perform 30:6650–6655

Wang J, Sun J, Zhang H, Dong S, Jiang J, Deng L et al (2018) Effect of spraying power on microstructure and property of nanostructured YSZ thermal barrier coatings. J Alloys Compd 730:471–482

Wang Q, Li Q, Zhang L, Chen DX, Jin H, Li JD et al (2022) Microstructure and properties of Ni-WC gradient composite coating prepared by laser cladding. Ceram Int 48:7905–7917

Winkless L (2015) Graphene coatings make steel corrosion-resistant. Elsevier

Winn AJ, Derby B, Webster JR, Holt S (2004) In situ characterization of interfaces between liquid tin–vanadium alloys and alumina by neutron reflection spectroscopy. J Am Ceram Soc 87:279–285

Xanthopoulou G, Marinou A, Vekinis G, Lekatou A, Vardavoulias M (2014) Ni-Al and NiO-Al composite coatings by combustion-assisted flame spraying. Coatings 4:231–252

Yao S-W, Li C-J, Tian J-J, Yang G-J, Li C-X (2016) Conditions and mechanisms for the bonding of a molten ceramic droplet to a substrate after high-speed impact. Acta Mater 119:9–25

Yin L, Murray BT, Singler TJ (2006) Dissolutive wetting in the Bi–Sn system. Acta Mater 54:3561–3574

Yin L, Chauhan A, Singler TJ (2008) Reactive wetting in metal/metal systems: dissolutive versus compound-forming systems. Mater Sci Eng A 495:80–89

Zhang C, Zhou H, Liu L (2014) Laminar Fe-based amorphous composite coatings with enhanced bonding strength and impact resistance. Acta Mater 72:239–251

Zhang Y, Hyland M, Tran AT, Matthews S (2016a) Effect of substrates temperatures on the spreading behavior of plasma-sprayed Ni and Ni-20 wt% Cr splats. J Therm Spray TechnOl 25:71–81

Zhang S, Wu J, Qi W, Wang J (2016b) Effect of porosity defects on the long-term corrosion behaviour of Fe-based amorphous alloy coated mild steel. Corros Sci 110:57–70

Zhang L, He T, Bai Y, Yu F-L, Fan W, Ma Y-S et al (2019) Velocity and temperature of in-flight particles and its significance in determining the microstructure and mechanical properties of TBCs. Acta Metall Sin (english Letters) 32:1269–1280

Zhang H, Wang S, Yang X, Hao S, Chen Y, Li H et al (2021) Interfacial characteristic and microstructure of Fe-based amorphous coating on magnesium alloy. Surf Coat Technol 425:127659

Zhong C, Liu F, Wu Y, Le J, Liu L, He M et al (2012) Protective diffusion coatings on magnesium alloys: a review of recent developments. J Alloy Compd 520:11–21

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest. Moreover, the authors have no relevant financial or non-financial interests to disclose. The authors have no competing interests to declare relevant to this article’s content.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qadir, D., Sharif, R., Nasir, R. et al. A review on coatings through thermal spraying. Chem. Pap. 78, 71–91 (2024). https://doi.org/10.1007/s11696-023-03089-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-023-03089-4