Abstract

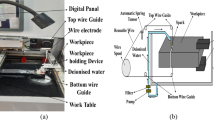

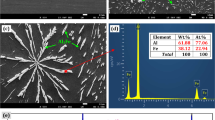

Wire-cut electrical discharge machining (WEDM) technology is used to cut composite materials. In this work, a hybrid composite of an aluminum matrix material reinforced with boron nitride and molybdenum disulfide (MoS2) was created utilizing the stir casting technique. Its WEDM machinability was investigated. The input parameters for the study are pulse on time (Ton), pulse off time (Toff), wire feed (WF), and wire tension (WT) output parameters material removal rate (MRR) and surface roughness (SR). The tests were designed using L27 orthogonal arrays. The analysis of variance was used to determine the contribution of input process characteristics impacting output performance. The ideal settings were determined using an entropy approach weight combined with the vise kriterijumska optimizacija kompromisno reseneje (VIKOR) method. In this work, the entropy weight criterion for MRR and SR were 0.52 and 0.48, respectively. The best ideal parameters were obtained from the VIKOR evaluation ratings at the (12th) trial, with a Ton of 8 μs, 28 μs of Toff, WF of 7 m/min, WT of 12 g and a higher appraisal grade of 1. A scanning electron microscope was used to analyze the surface morphology of the machined surface.

Similar content being viewed by others

References

T.W.W.P. Clyne, An Introduction to Metal Matrix Composites, J. R. Soc. Med., 2016, 55, p 7–8. https://doi.org/10.1007/s13398-014-0173-7.2

P.P. Jin, G. Chen, L. Han, and J.H. Wang, Dry Sliding Friction and Wear Behaviors of Mg2B2O5 Whisker Reinforced 6061Al Matrix Composites, Trans. Nonferrous Met. Soc. China (Engl. Ed.), 2014, 24, p 49–57. https://doi.org/10.1016/S1003-6326(14)63027-2

M. Ramesh, D. Jafrey Daniel, and M. Ravichandran, Investigation on Mechanical Properties and Wear Behaviour of Titanium Diboride Reinforced Composites, FME Trans., 2019, 47, p 873–879. https://doi.org/10.5937/fmet1904873R

G. Karthik Pandiyan and T. Prabaharan, Mechanical and Tribological Characterization of Stir Cast AA6061 T6-SiC Composite, SILICON, 2021, 13, p 4575–4582. https://doi.org/10.1007/s12633-020-00781-y

D. Jafrey Daniel James, L. Ganesh Babu, M. Ramesh, and M.M. Ravichandran, Mechanical and Tribological Characteristics of ZrO2 Reinforced Al2014 Matrix Composites Produced Via Stir Casting Route, Mater. Res. Express, 2019, 6, p 115542. https://doi.org/10.1088/2053-1591/ab4fc1

S.K. Pradhan, S. Chatterjee, A.B. Mallick, and D. Das, A Simple Stir Casting Technique for the Preparation of In Situ Fe-Aluminides Reinforced Al-Matrix Composites, Perspect. Sci., 2016, 8, p 529–532. https://doi.org/10.1016/j.pisc.2016.06.011

K. Ishfaq, S. Anwar, M.A. Ali et al., Optimization of WEDM for Precise Machining of Novel Developed Al6061-7.5% SiC Squeeze-Casted Composite, Int. J. Adv. Manuf. Technol., 2020, 111, p 2031–2049. https://doi.org/10.1007/s00170-020-06218-5

R.K. Garg, K.K. Singh, A. Sachdeva et al., Review of Research Work in Sinking EDM and WEDM on Metal Matrix Composite Materials, Int. J. Adv. Manuf. Technol., 2010, 50, p 611–624. https://doi.org/10.1007/s00170-010-2534-5

S. Sardar, S.K. Karmakar, and D. Das, Tribological Properties of Al 7075 Alloy and 7075/Al2O3 Composite Under Two-Body Abrasion: A Statistical Approach, J. Tribol., 2018 https://doi.org/10.1115/1.4039410

S. Sardar, S.K. Karmakar, and D. Das, Microstructure and Tribological Performance of Alumina-Aluminum Matrix Composites Manufactured by Enhanced Stir Casting Method, J Tribol, 2019 https://doi.org/10.1115/1.4042198

M. Renuka, K. Balaji, D. Sakthivadivel et al., Selection of Optimal Glazing Material for Solar Thermal Applications using Grey Relational Analysis, Int. J. Ambient Energy, 2021, 42, p 764–768. https://doi.org/10.1080/01430750.2018.1563820

A.R. Motorcu, E. Ekici, and A. Kuş, Investigation of the WEDM of Al/B4C/Gr Reinforced Hybrid Composites using the Taguchi method and Response Surface Methodology, Sci. Eng. Compos. Mater., 2016, 23, p 435–445. https://doi.org/10.1515/secm-2014-0063

S. Vellingiri, R. Soundararajan, N. Mohankumar et al., Exploration on WEDM Process Parameters Effect on LM13 Alloy and LM13/SiC Composites using Taguchi Method, Mater. Today Proc., 2021, 45, p 997–1003. https://doi.org/10.1016/j.matpr.2020.03.050

A. Kumar, N. Grover, A. Manna et al., Investigating the Influence of WEDM Process Parameters in Machining of Hybrid Aluminum Composites, Adv. Compos. Lett., 2020, 29, p 1–14. https://doi.org/10.1177/2633366x20963137

G. Anand, S. Sardar, A. Guha, and D. Das, WEDM Process Parameter Optimization of Al-Al3Fe In-Situ Composites, Mater. Today Proc., 2020, 33, p 5250–5256. https://doi.org/10.1016/j.matpr.2020.02.951

S.V. Kumar and M.P. Kumar, Experimental Investigation of the Process Parameters in Cryogenic Cooled Electrode in EDM, J. Mech. Sci. Technol., 2015, 29, p 3865–3871. https://doi.org/10.1007/s12206-015-0832-4

G. Selvakumar, G. Sornalatha, S. Sarkar, and S. Mitra, Experimental Investigation and Multi-Objective Optimization of Wire Electrical Discharge Machining (WEDM) of 5083 Aluminum Alloy, Trans. Nonferrous Met. Soc. China, 2014, 24, p 373–379. https://doi.org/10.1016/S1003-6326(14)63071-5

S. VinothKumar and M. PradeepKumar, Experimental Investigation and Optimization of Machining Process Parameters in AISI D2 Steel Under Conventional EDM and Cryogenically Cooled EDM Process, Trans. Indian Inst. Met., 2017, 70, p 2293–2301. https://doi.org/10.1007/s12666-017-1092-z

J.D. James Dhilip, J. Jeevan, D. Arulkirubakaran, and M. Ramesh, Investigation and optimization of parameters for hard turning of OHNS steel, Mater. Manuf. Process., 2020, 35, p 1113–1119. https://doi.org/10.1080/10426914.2020.1765254

B. Vvn, K.C. Varaprasad, and K. Prahlada Rao, Machinability Analysis on Wire Electrical Discharge Machining of Stir Casted AA2024/Al2O3/BN Hybrid Composite for Aerospace Applications, Mater. Manuf. Process, 2021, 36, p 730–743. https://doi.org/10.1080/10426914.2020.1854466

G.K. Pandiyan, T. Prabaharan, D.J.D. James, and V.N.T. Sivalingam, Improvement on the Machinability Characteristics of AA6061-T6/15 wt% SiC Composites by Response Surface Methodology, Surf. Topogr. Metrol. Prop., 2021, 9, p 35050. https://doi.org/10.1088/2051-672X/ac2560

A. Shekhovtsov and W. Sałabun, A Comparative Case Study of the VIKOR and TOPSIS Rankings Similarity, Procedia Comput. Sci., 2020, 176, p 3730–3740. https://doi.org/10.1016/j.procs.2020.09.014

K. Arun Vikram, T.V. Krishna Kanth, and P.R.D.V. Shabana, Response Optimization using VIKOR While Machining on Lathe under Dry and Minimum Quantity and Lubrication Conditions—A Case Study, Mater. Today Proc., 2020, 27, p 2487–2491. https://doi.org/10.1016/j.matpr.2019.09.223

R. Bhuyan and B. Routara, Optimization the Machining Parameters by using VIKOR and Entropy Weight Method during EDM Process of Al–18% SiCp Metal Matrix Composit, Decis. Sci. Lett., 2016, 5, p 269–282. https://doi.org/10.5267/j.dsl.2015.11.001

R. Kumar, Optimization of Process Parameters during CNC Turning by using AHP & VIKOR Method, Int J Eng Tech Res, 2018, 2, p 3478–3480.

J. Ma, W. Ming, J. Du et al., Integrated Optimization Model in Wire Electric Discharge Machining using Gaussian Process Regression and Wolf Pack Algorithm Approach While Machining SiCp/Al Composite, Adv. Mech. Eng., 2018, 10, p 1–17. https://doi.org/10.1177/1687814018787407

S.S. Mahapatra and A. Patnaik, Optimization of Wire Electrical Discharge Machining (WEDM) Process Parameters Using Taguchi Method. Int. J. Adv. Manuf. Technol., 2007, 34, p 911–925 (2007). https://doi.org/10.1007/s00170-006-0672-6

G. Karthik Pandiyan and T. Prabaharan, Optimization of Machining Parameters on AA6351 Alloy Steel using Response Surface Methodology (RSM), Mater. Today Proc., 2020, 33, p 2686–2689. https://doi.org/10.1016/j.matpr.2020.01.369

D. Srinivasan, N. Ganesh, D. Jafrey Daniel James, H. Ramakrishnan, R. Balasundaram, R. Sanjeevi, G.S.K.G. Karthik Pandiyan, and C. Mohanraj, Investigation of Surface Roughness and Material Removal Rate of WEDM of SS304 using ANOVA and Regression Models, Surf. Topogr. Metrol. Prop., 2022, 10, p 25014. https://doi.org/10.1088/2051-672x/ac6c9e

V. Sivalingam, P. Ganesh Kumar, R. Prabakaran et al., An Automotive Radiator with Multi-Walled Carbon-based Nanofluids: A Study on Heat Transfer Optimization using MCDM Techniques, Case Stud. Therm. Eng., 2022, 29, p 101724. https://doi.org/10.1016/j.csite.2021.101724

G.K. Pandiyan, T. Prabaharan, D.J.D. James, and V. Sivalingam, Machinability Analysis and Optimization of Electrical Discharge Machining in AA6061-T6/15wt% SiC Composite by the Multi-criteria Decision-Making Approach, J. Mater. Eng. Perform, 2021 https://doi.org/10.1007/s11665-021-06511-8

S.M. Shaaban and A.M. Abd El-latif, Integration of Evaluation Distance from Average Solution Approach with Information Entropy Weight for Diesel Engine Parameter Optimization, Int. J. Intell. Eng. Syst., 2020, 13, p 101–111. https://doi.org/10.22266/IJIES2020.0630.10

Funding

Future for Young Scholars of Shandong University, China [31360082064026][31360082164007]. This work is supported by Fundamental Research Funds of Shandong University [2019HW040].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhilip, J.D.J., Ganesan, K.P. & Sivalingam, V. Machinability Studies and Optimization of Process Parameters in Wire Electrical Discharge Machining of Aluminum Hybrid Composites by the VIKOR Method. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08323-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08323-4