Abstract

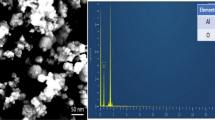

The present work accomplished homogenously disseminated ZrB2 reinforcement particles and very fine grain structure by multipass friction stir processing (MPFSP) of AA6082. They observed the influence of reinforcement particle ZrB2 on the microstructure and tensile properties of the MPFSP. The coarse dendrite structure of the base material AA6082 was studied using ZrB2 nanoparticles. The MPFSP/ZrB2 successfully shattered these coarse and dendrite clusters, resulting in a uniform microstructure in the stir zone. The MPFSP has observed material flow around the cluster's redistribution. At increased ZrB2 concentration, SEM and EBSD examinations demonstrated that ZrB2 reinforcement particles strongly inhibited grain boundary migration, resulting in a continual reduction in grain size and HAGBs fraction. The tensile properties and microstructure of the MPFSP/ZrB2 of AA6082 were enhanced using a rotational tool speed of 1120 rpm, welding speed of 125 mm/min, and tilt angle of 2°. The reinforcement particles ZrB2 were fragmented completely and uniformly disseminated in the 4th FSP pass. As the FSP increases, the ZrB2 agglomeration reduces. The base metal AA6082's ultimate tensile strength (UTS) was 191 ± 8 MPa with a % strain of 20 ± 0.8. After MPFSP/ZrB2 on AA6082, the UTS was increased as the FSP pass increased. The higher UTS (266 ± 5) was observed at the 4th FSP pass.

Similar content being viewed by others

Change history

31 October 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11665-023-08880-8

References

X. Zhang, S.F. Li, D. Pan, B. Pan, and K. Kondoh, Microstructure and Synergistic- Strengthening Efficiency of CNTs-SiC Dual-Nano Reinforcements in Aluminum Matrix Composites, Compos. Appl. Sci. Manuf., 2018, 105, p 87–96.

H. Mehdi and R.S. Mishra, Effect of Friction Stir Processing on Mechanical Properties and Heat Transfer of TIG Welded Joint of AA6061 and AA7075, Def. Technol., 2021, 17(3), p 715–727.

F. Khodabakhshi, M. Nosko, and A.P. Gerlich, Effect of Graphene Nano-Platelets (GNPs)on the Microstructural Characteristics and Textural Development of an Al-Mg Alloy during Friction-Stir Processing, Surf. Coat. Technol., 2018, 335, p 288–305.

A. Dolatkhah, P. Golbabaei, M.K.B. Givi, and F. Molaiekiya, Investigating Effects of Process Parameters on Microstructural and Mechanical Properties of Al5052/SiC Metal Matrix Composite Fabricated Via Friction Stir Processing, Mater. Des., 2012, 37, p 458–464.

M. Sharifitabar, A. Sarani, S. Khorshahian, and A.M. Shafiee, Fabrication of 5052Al/Al2O Nanoceramic Particle Reinforced Composite Via Friction Stir Processing Route, Mater. Des., 2011, 32, p 4164–4172.

W. Wang, Q.Y. Shi, P. Liu, H.K. Li, and T. Li, A Novel Way to Produce Bulk SiCp Reinforced Aluminum Metal Matrix Composites by Friction Stir Processing, J. Mater. Proc. Technol., 2009, 209(4), p 2099–2103.

E.R.I. Mahmoud, K. Ikeuchi, and M. Takahashi, Fabrication of SiC Particle Reinforced Composite on Aluminium Surface by Friction Stir Processing, Sci. Technol. Weld. Join., 2008, 13(7), p 607–618.

R.S. Mishra, Z.Y. Ma, and I. Charit, Friction Stir Processing: A Novel Technique for Fabrication of Surface Composite, Mater. Sci. Eng. A, 2003, 341(1–2), p 307–310.

H. Mehdi and R.S. Mishra, Microstructure and Mechanical Characterization of TIG-Welded Joint of AA6061 and AA7075 by Friction Stir Processing, Part L J. Mater. Des. Appl., 2021, 235(11), p 2531–2546. https://doi.org/10.1177/14644207211007882

H. Mehdi and R.S. Mishra, Effect of Friction Stir Processing on Mechanical Properties and Wear Resistance of Tungsten Inert Gas Welded Joint of Dissimilar Aluminum Alloys, J. Mater. Eng. Perform., 2021, 30, p 1926–1937.

H. Mehdi and R.S. Mishra, Influence of Friction Stir Processing on Weld Temperature Distribution and Mechanical Properties of TIG Welded Joint of AA6061 and AA7075, Trans. Indian Inst. Met., 2020, 73, p 1773–1788.

H. Mehdi and R.S. Mishra, Effect of Friction Stir Processing on Microstructure and Mechanical Properties of TIG Welded Joint of AA6061 and AA7075, Metallogr. Microstruct. Anal., 2020, 9, p 403–418. https://doi.org/10.1007/s13632-020-00640-7

H. Mehdi and R.S. Mishra, An Experimental Analysis and Optimization of Process Parameters of AA6061 and AA7075 Welded Joint by TIG+FSP Welding Using RSM, Adv. Mater. Process Technol., 2020 https://doi.org/10.1080/2374068X.2020.1829952

M. Narimani, B. Lotfi, and Z. Sadeghian, Investigating the Microstructure and Mechanical Properties of Al-TiB Composite Fabricated by Friction Stir Processing (FSP), Mater. Sci. Eng. A, 2016, 673, p 436–442.

K. Sun, Q.Y. Shi, Y.J. Sun et al., Microstructure and Mechanical Property of Nano-SiC Strength Mg Bulk Composites Produced by Friction Stir Processing, Mater. Sci. Eng. A, 2012, 547, p 32–37.

Y. Rui, Z. Zhang, Y. Zhao et al., Effect of Multi-Pass Friction Stir Processing on Microstructure and Mechanical Properties of Al3Ti/A356 Composites, Mater. Charact., 2015, 106, p 62–69.

L. Ceschini, I. Boromei, G. Minak, A. Morri, and F. Tarterini, Effect of Friction Stir Welding on Microstructure, Tensile and Fatigue Properties of the AA7005/10 vol.%Al2O3p Composite, Compos. Sci. Technol., 2007, 67, p 605–615.

L.M. Marzoli, A.V. Strombeck, J.F. Dos Santos, C. Gambaro, and L.M. Volpone, Friction Stir Welding of an AA6061/Al2O3/20p Reinforced Alloy, Compos. Sci. Technol., 2006, 66, p 363–371.

M. Amirizad, A.H. Kokabi, M.A. Gharacheh, R. Sarrafi, B. Shalchi, and M. Azizieh, Evaluation of Microstructure and Mechanical Properties in Friction Stir Welded A356 + 15%SiCp Cast Composite, Mater. Lett., 2006, 60, p 565–568.

X.G. Chen, M.D. Silva, P. Gougeon, and L. St-Georges, Microstructure and Mechanical Properties of Friction Stir Welded AA6063–B4C Metal Matrix Composites, Mater. Sci. Eng. A, 2009, 518, p 174–184.

S.J. Vijay and N. Murugan, Influence of Tool Pin Profile on the Metallurgical and Mechanical Properties of Friction Stir Welded Al–10 wt.% TiB2 Metal Matrix Composite, Mater. Des., 2010, 31, p 3585–3589.

H. Nami, H. Adgi, M. Sharifitabar, and H. Shamabadi, Microstructure and Mechanical Properties of Friction Stir Welded Al/Mg2Si Metal Matrix Cast Composite, Mater. Des., 2010, 32, p 976–983.

S. Gopalakrishnan and N. Murugan, Prediction of Tensile Strength of Friction Stir Welded Aluminium Matrix TiCp Particulate Reinforced Composite, Mater. Des., 2011, 32, p 462–467.

H.A. Deore, J. Mishra, A.G. Rao, H. Mehtani, and V.D. Hiwarkar, Effect of Filler Material and Post Process Ageing Treatment on Microstructure, Mechanical Properties and Wear Behaviour of Friction Stir Processed AA 7075 Surface Composites, Surf. Coat. Technol, 2019, 374, p 52–64.

H. Nami, H. Adgi, M. Sharifitabar, and H. Shamabadi, Microstructure and Mechanical Properties of Friction Stir Welded Al/Mg2Si Metal Matrix Cast Composite, Mater. Des., 2011, 32, p 976–983.

Z.Y. Zhanga, R. Yang, Y. Lia, G. Chena, Y.T. Zhao, and M.P. Liu, Microstructural Evolution and Mechanical Properties of Friction Stir Processed ZrB2/6061Al Nanocomposites, J. Alloys Compd., 2018, 762, p 312–318.

I. Dinaharan, N. Murugan, and S. Parameswaran, Developing an Empirical Relationship to Predict the Influence of Process Parameters on Tensile Strength of Friction Stir Welded AA6061/0–10 wt% ZrB2 In Situ Composite, Trans. Indian Inst. Met., 2012, 65, p 159–170.

N. Kumar, G. Gautam, R.K. Gautam, A. Mohan, and S. Mohan, Wear, Friction and Profilometer Studies of Insitu AA5052/ZrB2 Composites, Tribol. Int., 2016, 97, p 313–326.

E. Zapata-Solvas, D. Jayaseelan, H.-T. Lin, P. Brown, and W. Lee, Mechanical Properties of ZrB2-and HfB2-Based Ultra-High Temperature Ceramics Fabricated by Spark Plasma Sintering, J. Eur. Ceram. Soc., 2013, 33(7), p 1373–1386.

M.M. El-Rayes and E. El-Danaf, The Influence of Multi-Pass Friction Stir Processing on the Microstructural and Mechanical Properties of Aluminum Alloy 6082, J. Mater. Process. Technol., 2012, 212, p 1157–1168.

V. Sharma, U. Prakash, and B.V. Manoj Kumar, Surface Composites by Friction Stir Processing: A Review, J. Mater. Process. Technol., 2015, 224, p 117–134.

M. Barmouz, M.K.B. Givi, and J. Seyfi, On the Role of Processing Parameters in Producing Cu/SiC Metal Matrix Composites Via Friction Stir Processing: Investigating Microstructure, Microhardness, Wear and Tensile Behavior, Mater. Charact., 2011, 62, p 108–117.

R. Sathiskumar, N. Murugan, I. Dinaharan, and S.J. Vijay, Characterization of Boron Carbide Particulate Reinforced In Situ Copper Surface Composites Synthesized Using Friction Stir Processing, Mater. Charact., 2013, 84, p 16–27.

M. Barmouz, M.K. Besharati Givi, and J. Seyfi, On the Role of Processing Parameters in Producing Cu/SiC Metal Matrix Composites Via Friction Stir Processing: Investigating Microstructure, Microhardness, Wear and Tensile Behavior, Mater. Charact., 2011, 62, p 108–117.

C.J. Hsu, C.Y. Chang, P.W. Kao et al., Al–Al3Ti Nanocomposites Produced In Situ by Friction Stir Processing, Acta Mater., 2006, 54(19), p 5241–5249.

J.W. Martin, Micromechanisms in Particle Hardened Alloys, Cambridge University Press, Cambridge, 1980.

L. Jiang, H. Yang, J.K. Yee et al., Toughening of Aluminum Matrix Nanocomposites Via Spatial Arrays of Boron Trailing Side Carbide Spherical Nanoparticles, Acta Mater., 2016, 103, p 128–140.

M. Paidar, O.O. Ojo, H.R. Ezatpour, and A. Heidarzadeh, Influence of Multi-Pass FSP on the Microstructure, Mechanical Properties and Tribological Characterization of Al/B4C Composite Fabricated by Accumulative Roll Bonding (ARB), Surf. Coat. Technol., 2019, 361, p 159–169.

M. Barmouz and M.K. Besharati Givi, Fabrication of In Situ Cu/SiC Composites Using Multi-Pass Friction Stir Processing: Evaluation of Microstructural, Porosity, Mechanical and Electrical Behavior, Compos. Part A Appl. Sci. Manuf., 2011, 42(10), p 1445–1453.

S. Rathee, S. Maheshwari, A.N. Siddiquee, and M. Srivastava, Analysis of Microstructural Changes in Enhancement of Surface Properties in Sheet Forming of Al Alloys Via Friction Stir Processing, Mater. Today Proc., 2017, 4(2, Part A), p 452–458.

P. Su, A. Gerlich, T.H. North, and G.J. Bendzsak, Material Flow during Friction Stir Spot Welding, Sci. Technol. Weld. Join., 2013, 11(1), p 61–71.

O.P. Oladijo, A.M. Venter, L.A. Cornish, and N. Sacks, X-Ray Diffraction Measurement of Residual Stress in WC-Co Thermally Sprayed Coatings onto Metal Substrates, Surf. Coat. Technol., 2012, 206, p 4725–4729.

Z. Zhang and D.L. Chen, Consideration of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites: A Model for Predicting Their Yield Strength Author Links Open Overlay Panel, Scr. Mater., 2006, 54(7), p 1321–1326.

H. Mehdi and R.S. Mishra, Mechanical Properties and Microstructure Studies in Friction Stir Welding (FSW) Joints of Dissimilar Alloy- A Review, J. Achiev. Mater. Manuf. Eng., 2016, 77(1), p 31–40.

A. Simar, Y. Brechet, B.D. Meester, A. Denquin, C. Gallais, and T. Pardoen, Integrated Modeling of Friction Stir Welding of 6xxx Series Al Alloys: Process Microstructure and Properties, Prog. Mater. Sci., 2012, 57, p 95–183.

Z. Zhang, Z.Y. Wan, L.E. Lindgren, Z.J. Tan, and X. Zhou, The Simulation of Precipitation Evolutions and Mechanical Properties in Friction Stir Welding with Post Weld Heat Treatments, J. Mater. Eng. Perform., 2017, 26, p 5731–5740.

M. Srivastava, S. Rathee, and A.N. Siddiquee, Investigation on the Effects of Silicon Carbide and Cooling Medium during Multi-Pass FSP of Al-Mg/SiC Surface Composites, Silicon, 2019, 11, p 2149–2157.

M.M. Moradi, H.J. Aval, R. Jamaati, S. Amirkhanlou, and S. Ji, Microstructure and Texture Evolution of Friction Stir Welded Dissimilar Aluminum Alloys: AA2024 and AA6061, J. Manuf. Process., 2018, 32, p 1–10.

X.C. Liu, Y.F. Sun, T. Nagira, K. Ushioda, and H. Fujii, Evaluation of Dynamic Development of Grain Structure during Friction Stir Welding of Pure Copper using a Quasi In Situ Method, J. Mater. Sci. Technol., 2019, 35, p 1412–1421.

M. Barmouz and M.K. Besharati Givi, Fabrication of In Situ Cu/SiC Composites using Multi-Pass Friction Stir Processing: Evaluation of Microstructural, Porosity, Mechanical and Electrical Behavior, Compos. Part A Appl. Sci. Manuf., 2011, 42, p 1445–1453.

J.Q. Su, T.W. Nelson, R. Mishra, and M. Mahoney, Microstructural Investigation Friction Stir Welded 7050–T651 Aluminium, Acta Mater., 2003, 51, p 713–729.

P.B. Prangnell and C.P. Heason, Grain Structure Formation during Friction Stir Welding Observed by the “Stop Action Technique,” Acta Mater., 2005, 53, p 3179–3192.

L.B. Johannes and R.S. Mishra, Multiple Passes of Friction Stir Processing for the Creation of Superplastic 7075 Aluminum, Mater. Sci. Eng. A, 2007, 464(1), p 255–260.

G.Q. Huang, J. Wu, W.T. Hou, L.H. Shah, A.R.H. Midawi, A.P. Gerlich, Y.F. Shen, and F.Q. Meng, Microstructural Evolution and Mechanical Behavior of Powder Metallurgy Based SiC/Al–Mg-Sc-Zr Nanocomposite Subjected to Multi-Pass Friction Stir Processing, Mater. Sci. Eng. A, 2021, 806, 140831.

M. Abbasi, M. Givi, and A. Ramazani, Friction Stir Vibration Processing: A New Method to Improve the Microstructure and Mechanical Properties of Al5052/SiC Surface Nanocomposite Layer, Int. J. Adv. Manuf. Technol., 2019, 100, p 1463–1473.

G. AzimiRoeen, S.F. Kashani-Bozorg, M. Nosko, and S. Lotfian, Mechanical and Microstructural Characterization of Hybrid Aluminum Nanocomposites Synthesized from an Al–Fe3O4 System by Friction Stir Processing, Met. Mater. Int., 2019, 26(9), p 1441–1453.

F. Khodabakhshi, M. Haghshenas, J. Chen, B. Shalchi Amirkhiz, J. Li, and A.P. Gerlich, Bonding Mechanism and Interface Characterisation during Dissimilar Friction Stir Welding of an Aluminium/Polymer Bi-Material Joint, Sci. Technol. Weld. Join., 2017, 22, p 182–190.

H. Mehdi and R.S. Mishra, Consequence of Reinforced SiC Particles on Microstructural and Mechanical Properties of AA6061 Surface Composites by Multi-Pass FSP, J. Adhes. Sci. Technol., 2021 https://doi.org/10.1080/01694243.2021.1964846

M. Koilraj, V. Sundareswaran, S. Vijayan, and S.R.K. Rao, Friction Stir Welding of Dissimilar Aluminum Alloys AA2219 to AA5083- Optimization of Process Parameters using Taguchi Technique, Mater. Des., 2012, 42, p 1–7.

O.T. Middling, L.D. Oosterkamp, and J. Bersaas, Friction stir welding aluminium process and applications. In: Proceedings of the Seventh International Conference on 'Joints in Aluminum', INALCO98, 1998.

M. Paidar, A. Asgari, O.O. Ojo, and A. Saberi, Mechanical Properties and Wear Behavior of AA5182/WC Nanocomposite Fabricated by Friction Stir Welding at Different Tool Traverse Speeds, J. Mater. Eng. Perform., 2018, 27, p 1714–1724.

D.K. Sharma, V. Patel, V. Badheka, K. Mehta, and G. Upadhyay, Fabrication of Hybrid Surface Composites AA6061/(B4 C+MoS ) Via Friction Stir Processing, J. Tribol., 2019, 141(5), p 52201–52210.

Y.B. Tan, X.M. Wang, M. Ma, J.X. Zhang, W.C. Liu, R.D. Fu, and S. Xiang, A Study on Microstructure and Mechanical Properties of AA3003 Aluminum Alloy Joints by Underwater Friction Stir Welding, Mater. Charact., 2017, 127, p 41.

D. Canadinc, E. Biyikli, T. Niendorf, and H.J. Maier, Experimental and Numerical Investigation of the Role of Grain Boundary Misorientation Angle on the Dislocation-Grain Boundary Interactions, Adv. Eng. Mater., 2011, 13(4), p 281.

K.T. Huang, T.S. Lui, and L.H. Chen, Effect of Microstructural Feature on the Tensile Properties and Vibration Fracture Resistance of Friction Stirred 5083 Alloy, J. Alloys Compd., 2011, 509(27), p 7466.

S.S. Mirjavadi, M. Alipour, A.M.S. Hamouda, A. Matin, S. Kord, B.M. Afshari, and P.G. Koppad, Effect of Multi-Pass Friction Stir Processing on the Microstructure, Mechanical and Wear Properties of AA5083/ZrO2 Nanocomposites, J. Alloys Compd., 2017, 726, p 1262–1273.

M. Bodaghi and K. Dehghani, Friction Stir Welding of AA5052: The Effects of SiC Nanoparticles Addition, Int. J. Adv. Manuf. Technol., 2017, 88, p 2651–2660.

A. Heidarzadeh, R.V. Barenji, M. Esmaily, and A.R. Ilkhichi, Tensile Properties of Friction Stir Welds of AA 7020 Aluminum Alloy, Trans. Indian Inst. Met., 2015, 68, p 757–767.

H.J. Liu, H. Fujii, M. Maeda, and K. Nogi, Tensile Properties and Fracture Locations of Friction-Stir-Welded Joints of 2017–T351 Aluminum Alloy, J Mat. Proc. Technol, 2013, 142, p 692–696.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mehdi, H., Mishra, R.S. Modification of Microstructure and Mechanical Properties of AA6082/ZrB2 Processed by Multipass Friction Stir Processing. J. of Materi Eng and Perform 32, 285–295 (2023). https://doi.org/10.1007/s11665-022-07080-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07080-0