Abstract

Compared to other stainless steels, the supermartensitic stainless steels (SMSS) are a new sub-family with improved weldability and mechanical and corrosion resistance properties. Besides the drastic reduction of carbon content and Ni and Mo addition, these steels may also contain microadditions of Ti, Nb, V and/or N to the improve mechanical resistance. These materials are mainly used as seamless pipes for casings and tubulars for oil and gas off-shore production. After hot rolling (Mannesman process), the tubes are quenched and tempered to achieve the required mechanical properties. Tempering temperature is adjusted as function of the class of mechanical resistance, 95 ksi or 110 ksi. In this work, based on the mechanical properties data, the heat treatment used to produce steels of classes 95 and 100 ksi were determined. The microstructural features of the as tempered steel were investigated and compared to the microstructure of specimens treated for classes 95 ksi and 110 ksi.

Similar content being viewed by others

References

C.V.L. Sabará, L.N.S. Prachedes, L.C. Santos, M.A. Sabará, R.C. Souza, A.F. Sene et al., Influence of Parameters Related to Microstructure, Chemical Composition and Environment Characteristics on Localized Corrosion Failure Susceptibility of Supermartensitic Stainless Steels, Eng. Fail. Anal., 2021, 127, p 66. https://doi.org/10.1016/j.engfailanal.2021.105524.

X. He, X. Lü, Z. Wu, S. Li, Q. Yong, J. Liang et al., M23C6 Precipitation and Si Segregation Promoted by Deep Cryogenic Treatment Aggravating Pitting Corrosion of Supermartensitic Stainless Steel, J. Iron Steel Res. Int., 2021, 28, p 629–40. https://doi.org/10.1007/s42243-020-00514-w.

I.G.R. Santos, F.F. de Assis, R. Silva, G.D. Zepon and C.A. Rovere, Corrosion Resistance of UNS S41426 Stainless Steel in Acid Media and Its Relation to Chemical Partition and Austenite Fraction, Corros. Sci., 2021, 188, p 109–519. https://doi.org/10.1016/j.corsci.2021.109519.

Z. Ding, Y. Zhao, R. Lu, H. Pei and H. Hou, Microstructure Evolution and Mechanical Properties of Mg-10Gd-3Y-xZn-0.6Zr Alloys, J. Mater. Res., 2018, 33, p 1797–805. https://doi.org/10.1557/jmr.2018.100.

F.P. Pickering, Physical Metallurgy of Stainless Steels, Int. Met. Rev., 1976, 66, p 227–67. .

L. Xu, J. Shi, W.Q. Cao, M.Q. Wang, W.J. Hui and H. Dong, Yield Strength Enhancement of Martensitic Steel through Titanium Addition, J. Mater. Sci., 2011, 46, p 3653–3658. https://doi.org/10.1007/s10853-011-5282-5.

Y. Lian, J. Huang, J. Zhang, C. Zhang, W. Gao and C. Zhao, Effect of 0.2 and 0.5% Ti on the Microstructure and Mechanical Properties of 13Cr Supermartensitic Stainless Steel, J. Mater. Eng. Perform., 2015, 24, p 4253–9. https://doi.org/10.1007/s11665-015-1749-x.

C.A.D. Rodrigues, P.L.D. Lorenzo, A. Sokolowski, C.A. Barbosa and J.M.D.A. Rollo, Titanium and Molybdenum Content in Supermartensitic Stainless Steel, Mater Sci Eng A, 2007, 460–461, p 149–152. https://doi.org/10.1016/j.msea.2007.01.016.

NACE. NACE 0175/ISO 15156-3 Petroleum and Natural Gas Industries—Materials for Use in H2S-Containing Environments in Oil and Gas Production. Part 3: Cracking-Resistant Carbon and Low-Alloy Steels, and the Use of Cast Irons. NACE International; 2015.

J. Zhang, J. Li, C. Shi and J. Huang, Growth and Agglomeration Behaviors of Eutectic M7C3 Carbide in Electroslag Remelted Martensitic Stainless Steel, J. Mater. Res. Technol., 2021, 11, p 1490–1505. https://doi.org/10.1016/j.jmrt.2021.01.113.

R.B. Soares, L.F.P. Dick, S.M. Manhabosco, A.P. dos Santos, W.R. da Costa Campos, J.D. Ardisson et al., Metallurgical and Electrochemical Characterization of a Supermartensitic Steel, Mater. Res., 2020, 23, p 1–11. https://doi.org/10.1590/1980-5373-MR-2019-0280.

G.S. Pandolfi, S.C. Martins, V.T.L. Buono and L.A. Santos, Precipitation Kinetics of Ti3Ni4 and Multistage Martensitic Transformation in an Aged Ni–rich Ni–Ti Shape Memory Alloy, J. Mater. Res. Technol., 2020, 9, p 9162–9173. https://doi.org/10.1016/j.jmrt.2020.06.046.

S. Zappa, H.G. Svoboda, N.M. Ramini de Rissone, E.S. Surian and L.A. De Vedia, Improving Supermartensitic Stainless Steel Weld Metal Toughness, Weld. J., 2012, 91, p 83–90. .

J.E. Ramirez, Weldability Evaluation of Supermartensitic Stainless Pipe Steels, Weld. J., 2007, 86, p 125–134. .

S.S.M. Tavares, C.R. Rodrigues, J.M. Pardal, B.E. Da Silva and H.F.G. De Abreu, Effects of Post Weld Heat Treatments on the Microstructure and Mechanical Properties of Dissimilar Weld of Supermartensític Stainless Steel, Mater. Res., 2014, 17, p 1336–1343. https://doi.org/10.1590/1516-1439.299314.

F. Foroozmehr and P. Bocher, An Investigation on Fracture Toughness of the Heat-Affected Zone in the Welded Joints of 13% Cr-4% Ni Martensitic Stainless Steels, Fatigue Fract. Eng. Mater. Struct., 2021, 44, p 3416–3430. https://doi.org/10.1111/ffe.13569.

NACE. NACE 0175/ISO 15156-2 Petroleum and Natural Gas Industries—Materials for Use in H2S-Containing Environments in Oil and Gas Production. Part 2: Cracking-Resistant CRAs (Corrosion-Resistant Alloys) and Other Alloys. NACE International; 2015.

M. De Sanctis, G. Lovicu, R. Valentini, A. Dimatteo, R. Ishak, U. Migliaccio et al., Microstructural Features Affecting Tempering Behavior of 16Cr-5Ni Supermartensitic Steel, Metall. Mater. Trans. A, 2015, 46, p 1878–1887. https://doi.org/10.1007/s11661-015-2811-x.

T.G. Gooch, Heat Treatment of Welded 13%Cr-4%Ni Martensitic Stainless Steels for Sour Service, Weld. J., 1995, 74, p 213–223. .

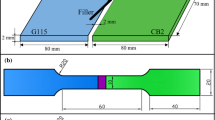

ASTM. ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International; 2016. https://doi.org/10.1520/A0370-16.2.

ASTM. ASTM E23 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International; 2007. https://doi.org/10.1520/E0023-07AE01.2.

S.S.M. Tavares, L.F. Noris, J.M. Pardal and M.R. da Silva, Temper Embrittlement of Supermartensitic Stainless Steel and Non-Destructive Inspection by Magnetic Barkhausen Noise, Eng. Fail. Anal., 2019, 100, p 322–328. https://doi.org/10.1016/j.engfailanal.2019.02.034.

H.J. Hollomon, Tensile Deformation, Trans. AIME, 1945, 162, p 268–290. .

S.M. Kraft and A.P. Gordon, Characterization of the Tensile Behavior of a Metallic Fiber Woven Structure, Text. Res. J., 2011, 81, p 1249–1272. https://doi.org/10.1177/0040517511398944.

ISO. ISO 13680 Petroleum and Natural Gas Industries—Corrosion-Resistant Alloy Seamless Tubular Products for Use as Casing, Tubing, Coupling Stock and Accessory Material—Technical Delivery Conditions. ISO International Standard; 2020.

S.S.M. Tavares, B.B. Almeida, D.A.L. Corrêa and J.M. Pardal, Failure of Super 13Cr Stainless Steel Due to Excessive Hardness in the Welded Joint, Eng. Fail. Anal., 2018, 91, p 92–98. https://doi.org/10.1016/j.engfailanal.2018.04.018.

ASTM. ASTM E140 Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness. ASTM International; 2013. https://doi.org/10.1520/E0140-12B.1.

J.D. Escobar, J.D. Poplawsky, G.A. Faria, J. Rodriguez, J.P. Oliveira, C.A.F. Salvador et al., Compositional Analysis on the Reverted Austenite and Tempered Martensite in a Ti-Stabilized Supermartensitic Stainless Steel: Segregation, Partitioning and Carbide Precipitation, Mater. Des., 2018, 140, p 95–105. https://doi.org/10.1016/j.matdes.2017.11.055.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tavares, S.S.M., Pimenta, A.R., Cardoso, A.S.M. et al. Microstructure and Mechanical Properties of Ti-Alloyed Supermartensitic 12%Cr Stainless Steel Classes 95 ksi and 110 ksi for Oil and Gas Production. J. of Materi Eng and Perform 31, 8004–8012 (2022). https://doi.org/10.1007/s11665-022-06872-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06872-8