Abstract

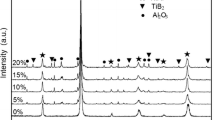

Fe-Al-x%TiC composite porous materials were synthesized by the reaction of Fe+Al+TiC mixed powder. By adding a certain proportion of TiC to try to control the self-propagating high-temperature synthesis (SHS) reactions of Fe and Al during the sintering process, the effects of adding TiC on the porosity, phase, and oxidation resistance of Fe-Al-based porous materials were studied. The results showed that the porosity of Fe-Al-x%TiC green compacts increased from 22.83 to 24.89% with an increase in the proportion of TiC, and TiC did not affect the phase change during the sintering process. In the DSC curve, after the addition of TiC, the temperature of the exothermic peak of Fe and Al increased during the sintering process, proving that the reaction between Fe and liquid Al is delayed. When TiC was 4 and 6 wt.%, an endothermic peak appeared when Al melted, which further showed that the SHS reaction was suppressed. In addition, the porous Fe-Al-x%TiC composite sintered at 1000 °C has better oxidation resistance and decreases with increasing TiC content, while the compression resistance increases with increasing TiC content.

Similar content being viewed by others

References

H. Sina, J. Corneliusson, K. Turba and S. Iyengar, A Study on the Formation of Iron Aluminide (FeAl) from Elemental Powders, J. Alloy Compd., 2015, 636, p 261–269.

J.H. Choi, I.S. Ahn, Y.C. Bak, S.Y. Bae, S.J. Ha and H.J. Jang, Preparation of High Porous Metal Filter Element for the Fail-Safety Function, Powder Technol., 2004, 140, p 98–105.

E.C. Hammel, L.R. Ighodaro and O.I. Okoli, Processing and Properties of Advanced Porous Ceramics: An Application Based Review, Ceram. Int., 2014, 40(10), p 15351–15370.

L. Lefebvre, J. Banhart and D.C. Dunand, Porous Metals and Metallic Foams: Current Status and Recent Developments, Adv. Eng. Mater., 2008, 10(9), p 775–787.

X. Cai, Y. Liu, P. Feng, X. Jiao, L. Zhang and J. Wang, Fe-Al Intermetallic Foam with Porosity Above 60 % Prepared by Thermal Explosion, J. Alloy Compd., 2017, 732, p 443–447.

S. Azem, M. Nechiche and K. Taibi, Development of Copper Matrix Composite Reinforced with FeAl Particles Produced by Combustion Synthesis, Powder Technol., 2011, 208(2), p 515–520.

Q. Wang, X. Leng, T. Yang and J. Yan, Effects of Fe-Al Intermetallic Compounds on Interfacial Bonding of Clad Materials, Trans. Nonferrous Metal. Soc., 2014, 24(1), p 279–284.

E. Poche, S.A.J. Wiak, K. Karczewski and Z. Bojar, Fe–Al Phase Formation Around SHS Reactions under Isothermal Conditions, J. Alloy Compd., 2011, 509(4), p 1124–1128.

M. Amaya, M.A. Espinosa-Medina, J. Porcayo-Calderon, L. Martinez and J.G. Gonzalez-Rodriguez, High Temperature Corrosion Performance of FeAl Intermetallic Alloys in Molten Salts, Mater. Sci. Eng. A, 2003, 349, p 12–19.

C. Xiaoping, L. Yanan, W. Xiaohong, J. Xinyang, W. Jianzhong, A. Farid and F. Peizhong, Oxidation Resistance of Highly Porous Fe-Al Foams Prepared by Thermal Explosion, Metall. Mater. Trans. A, 2018, 49, p 3683–3691.

H. Gao, Y. He, P. Shen, J. Zou, N. Xu, Y. Jiang, B. Huang and C.T. Liu, Porous FeAl Intermetallics Fabricated by Elemental Powder Reactive Synthesis, Intermetallics, 2009, 17(12), p 1041–1046.

M. Łazińska, T. Durejko, S. Lipiński, W. Polkowski, T. Czujko and R.A. Varin, Porous Graded FeAl Intermetallic Foams Fabricated by Sintering Process Using NaCl Space Holders, Mater. Sci. Eng. A, 2015, 636, p 407–414.

H.Y. Gao, Y.H. He, P.Z. Shen, Y. Jiang and C.T. Liu, Effect of Pressure on Pore Structure of Porous FeAl Intermetallics, Adv. Powder Technol., 2015, 26(3), p 882–886.

H.Y. Gao, Y.H. He, J. Zou, P.Z. Shen, Y. Jiang and C.T. Liu, Mechanical Properties of Porous Fe–Al Intermetallics, Powder Metall., 2014, 58(3), p 197–201.

H. Gao, W. Xie, H. Zhang, W. Shen, Y. He, Modification of the Reactive Synthesis of Porous FeAl with Addition of Si. Materials at High Temperatures., 2018. https://doi.org/10.1080/09603409.2018.1439683

H.Y. Gao, Y.H. He, J. Zou, N.P. Xu and C.T. Liu, Pore Structure Control for Porous FeAl Intermetallics, Intermetallics, 2013, 32, p 423–428.

Y.N. Liu, Z. Sun, X.P. Cai, X.Y. Jiao and P.Z. Feng, Fabrication of Porous FeAl-Based Intermetallics via Thermal Explosion, Trans. Nonferrous Metal. Soc., 2018, 28(6), p 1141–1148.

D.E. Alman and R.D. Govier, Influence of Al Additions on the Reactive Synthesis of MoSi2, Scr. Mater., 1996, 34(8), p 1287–1293.

M. Chojnacki, S. Jóźwiak, K. Karczewski and Z. Bojar, Modification of Fe and Al Elemental Powders’ Sintering with Addition of Magnesium and Magnesium Hydride, Intermetallics, 2011, 19(10), p 1555–1562.

K. Karczewski, S. Jówiak, M. Chojnacki and Z. Bojar, The Influence of Different Additives on the Kinetics of Self-Propagating High-Temperature Synthesis during the Sintering Process of Fe and Al Elemental Powders, Intermetallics, 2010, 18(7), p 1401–1404.

H. Zhang, W. Xie, H. Gao, W. Shen and Y. He, Suppression of the SHS Reactions during Synthesis of Porous FeAl Intermetallics by Introducing Silicon, J. Alloy Compd., 2018, 735, p 1435–1438.

P. Novák, V. Knotek, J. Šerák, A. Michalcová and D. Vojtěch, Synthesis of Fe–Al–Si Intermediary Phases by Reactive Sintering, Powder Metall., 2011, 54(2), p 167–171.

J.J. Moore and H.J. Feng, Combustion Synthesis of Advanced Materials, Prog. Mater. Sci., 1995, 39(4–5), p 243–273.

B. Tozkoparan, B. Dikici, M. Topuz, F. Bedir and M. Gavgali, Al-5Cu/B4Cp Composites: The Combined Effect of Artificially Aging (T6) and Particle Volume Fractions on the Corrosion Behaviour, Adv. Powder Technol., 2020, 31(7), p 2833–2842.

R. Ekici and E. Kosedag, Comparison of the Low-Velocity Impact Behaviors of SIC and Pumice Particle-Reinforced Metal Matrix Composites, Int. J. Mech. Prod. Eng., 2017, 5(10), p 101–105.

E. Kosedag and R. Ekici, Low-Velocity Impact Performance of B4C Particle-Reinforced Al 6061 Metal Matrix Composites, Mater. Res. Express, 2019, 6(12), Article no. 126556.

F. Quncheng, C. Huifen and J. Zhihao, Effects of Particle Size of Reactant on Characteristics of Combustion Synthesis of TiC-Fe Cermet, J. Mater. Sci., 2002, 37, p 2251–2257.

Y. Jiang, Y.H. He, N.P. Xu, J. Zou, B.Y. Huang and C.T. Liu, Effects of the Al Content on Pore Structures of Porous Ti–Al Alloys, Intermetallics, 2008, 16(2), p 327–332.

C. Xu, L. Chen, C. Zheng, H. Zhang, C. Zhao, Z. Wang, S. Lu, J. Zhang and L. Zhang, Improved Wear and Corrosion Resistance of Microarc Oxidation Coatings on Ti–6Al–4V Alloy with Ultrasonic Assistance for Potential Biomedical Applications, Adv. Eng. Mater., 2021, 23(4), Article no. 2001433.

P. Sang, L. Chen, C. Zhao, Z. Wang, H. Wang, S. Lu, D. Song, J. Xu and L. Zhang, Particle Size-Dependent Microstructure, Hardness and Electrochemical Corrosion Behavior of Atmospheric Plasma Sprayed NiCrBSi Coatings, Metals, 2019, 9(12), Article no. 1342.

M. Fan, B. Jianbin, High temperature oxidation resistance of Fe3Al/TiC composites. Journal of Sanmenxia Polytechnic., 2003, (02), p 64–66. (in Chinese)

C. Moral and A. Bautista, Thermogravimetric Study of the Oxidation Behaviour of Sintered Stainless Steels: Influence of Powder Size and Composition, Mater. Sci. Forum., 2012, 727–728, p 108–113.

A. Scherf, D. Janda, M.B. Yazdi, X. Li, F. Stein and M. Heilmaier, Oxidation Behavior of Binary Aluminium-Rich Fe–Al Alloys with a Fine-Scaled, Lamellar Microstructure, Oxid. Met., 2015, 83(5–6), p 559–574.

J. Cebulski and S. Lalik, Kinetics of Corrosion Processes of Alloy on the Intermetallic Phase Matrix FeAl in High Temperature in Air Atmosphere, Solid State Phenom., 2014, 212, p 137–140.

H.Y. Gao, Y.H. He, P.Z. Shen, J. Zou, N.P. Xu, Y. Jiang, B.Y. Huang and C.T. Liu, Effects of Al Content on Porous Fe-Al alloys, Powder Metall., 2009, 52(2), p 158–163.

F.X. Liu, L. Yong, B.Y. Huang, Y.H. He and K.C. Zhou, Fabrication of FeAl/TiC Composites through Reactive Hot Pressing, J. Cent. South Univ., 2004, 11(4), p 343–347. (in Chinese)

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant No. 51704255), the City-University (Nanchong City-Southwest Petroleum University) Science and Technology Strategic Cooperation Project (SXQHJH055 and SXHZ054) and Key Laboratory of Oil and Gas Field Materials in Sichuan Province Colleges and Universities (X151521KCL05).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wen, X., Huang, B., Xie, Y. et al. Preparation and Properties of Porous Fe-Al-x%TiC Composite Material. J. of Materi Eng and Perform 31, 8596–8604 (2022). https://doi.org/10.1007/s11665-022-06835-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06835-z