Abstract

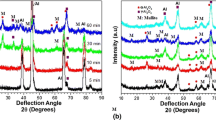

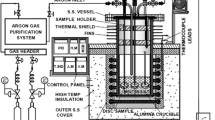

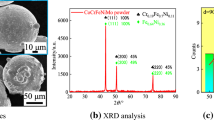

The effect of electrical process parameters like frequency and duty cycle on structural, morphological, and corrosion behaviour of nanocrystalline ceramic oxide coatings developed by plasma electrolytic oxidation (PEO) with pulsating DC power on laser sintered Ti-6Al-4V alloy is investigated in this study. Samples were coated with different combinations of frequency (1 kHz and 50 Hz) and duty cycle (90 and 20%). XRD patterns affirm that the coatings are predominantly comprised of anatase and rutile phases. The SEM analysis shows significant variation in pore size (2-10 µm) and thickness of coatings (10.1-13.2 µm). The high-frequency PEO coating exhibited a smoother surface. Overall, the findings suggest that duty cycle and frequency considerably impact pore morphology, surface roughness, and corrosion behaviour of laser sintered Ti-6Al-4V alloy coatings. The sample treated with 90% duty cycle and 1 kHz frequency reported three folds increase in corrosion resistance than the uncoated substrate.

Similar content being viewed by others

References

M. Peters, J. Kumpfert, C.H. Ward and C. Leyens, Titanium Alloys for Aerospace Applications, Titanium and Titanium Alloys. C. Leyans, M. Peters Ed., Wiley, Weinheim, 2003, p 333–349

G. Lutjering and J.C. Williams, Titanium, 2nd ed. Springer, Berlin, 2007.

M.J. Donachie Jr., Titanium: A Technical Guide, ASM international, Ohio, 2000.

S. Kumar and A. Mandal, Laser Cladding of Titanium Alloys, Laser Cladding of Metals. P. Cavaliere Ed., Springer, Switerzerland, 2021, p 215–238

R. Konečná, L. Kunz, A. Bača and G. Nicoletto, Resistance of Direct Metal Laser Sintered Ti6Al4V Alloy Against Growth of FATIGUE CRACKS, Eng. Fract. Mech., 2017, 185, p 82–91.

Z. Yang, Y. Xu, R.D. Sisson and J. Liang, Factors Influencing the Corrosion Behavior of direct Metal Laser Sintered Ti-6Al-4V for biomedical applications, J. Mater. Eng. Perform., 2020, 29, p 3831–3839.

V.N. Moiseyev, Titanium Alloys: Russian aircraft and Aerospace applications, CRC Press, Newyork, 2006.

I. Smokovych, M. Scheffler, S. Li and B. Yao, New-Type Oxidation Barrier Coatings for Titanium Alloys, Adv. Eng. Mater., 2020, 22, p 1901224.

D. Pavlenko, Y. Dvirnyk and R. Przysowa, Advanced Materials and Technologies for Compressor BLADES of Small Turbofan Engines, Aerospace, 2021, 8, p 1–16.

G.D. Revankar, R. Shetty, S. Srinivasarao and V.N. Gaithonde, Wear Resistance Enhancement of Titanium Alloy (Ti-6Al-4V) by Ball Burnishing Process, J. Mater. Res. Technol., 2017, 6(1), p 13–32.

K. Aniolek, A. Barylski and M. Kupka, Friction and Wear of Oxide Scale Obtained on Pure Titanium after High-Temperature Oxidation, Materials., 2021, 14, p 3764.

J. Dai, J. Zhu, C. Chen and F. Weng, High Temperature Oxidation Behavior and Research Status of Modifications on Improving High Temperature Oxidation Resistance of Titanium Alloys And Titanium Aluminides: A Review, J. Alloys Compd., 2016, 685, p 784–798.

L.C. Zhang, L.Y. Chen and L. Wang, Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests, Adv. Eng. Mater., 2020, 2020(22), p 1901258.

M. Dominik, A. Leśniewski, M. Janczuk, J.N. Jönsson, M. Hołdyński, Ł Wachnicki, M. Godlewski, W.J. Bock and M. Śmietana, Titanium Oxide Thin Films Obtained with Physical and Chemical Vapour Deposition Methods for Optical Biosensing Purposes, Biosens. Bioelectron., 2017, 93, p 102–109.

X. Li, C. Dong, Q. Zhao, Y. Pang, F. Cheng and S. Wang, Characterization of Microstructure and Wear Resistance of PEO Coatings Containing Various Microparticles on Ti6Al4V Alloy, J. Mater. Eng. Perform., 2018, 27, p 1642–1653.

P. Gkomoza, G.S. Lampropoulos, M. Vardavoulias, D.I. Pantelis, P.N. Karakizis and Ch. Sarafoglou, Microstructural Investigation of Porous Titanium Coatings, Produced by Thermal Spraying Techniques, Using Plasma Atomisation and Hydridedehydride Powders, for Orthopedic Implants, Surf. Coat. Technol., 2019, 357, p 947–956.

C.S. Chen, J.H. Chang, V. Srimaneepong, J.Y. Wen, O.H. Tung, C.H. Yang, H.C. Lin, T.H. Lee, Y. Han and H.H. Huang, Improving the In Vitro Cell Differentiation and In Vivo Osseointegration of Titanium Dental Implant Through Oxygen Plasma Immersion Ion Implantation Treatment, Surf. Coat. Technol., 2020, 399, p 126125.

X. Lu, M. Mohedano, C. Blawert, E. Matykina, R. Arrabal, K.U. Kainer and M.L. Zheludkevich, Plasma Electrolytic Oxidation Coatings with Particle Additions: A Review, Surf. Coat. Technol., 2016, 307, p 1165–1182.

C. Premchand, S. Hariprasad, A. Saikiran, E. Lokeshkumar, P. Manojkumar, B. Ravisankar, B. Venkataraman and N. Rameshbabu, Assessment of Corrosion and Scratch Resistance of Plasma Electrolytic Oxidation and Hard Anodized Coatings Fabricated on AA 7075-T6, Trans. Indian Inst. Met., 2021, 74(8), p 991–2002.

E. Ramakrishnan, C. Premchand, P. Manojkumar and N. Rameshbabu, Development of Thermal Control Coatings on AA7075 by Plasma Electrolytic Oxidation (PEO) Process, Mater. Today: Proc., 2021, 46, p 1085–1090.

S. Ahmadnia, S. Aliasghari and M. Ghorbani, Improved Electrochemical Performance of Plasma Electrolytic Oxidation Coating on Titanium in Simulated Body Fluid, J. Mater. Eng. Perform., 2019, 28, p 4120–4127.

S. Hariprasad, A. Saikiran, C. Premchand, L. Ramakrishna and N. Rameshbabu, Fabrication of Ceramic Coatings on the Biodegradable ZM21 Magnesium Alloy by PEO Coupled EPD Followed by Laser Texturing Process, J. Magnes. Alloy., 2021, 9, p 910–926.

E. Lokeshkumar, P. Manojkumar, A. Saikiran, C. Premchand, S. Hariprasad, L. Ramakrishna and N. Rameshbabu, Fabrication of Ca and P Containing Niobium Oxide Ceramic Coatings on Niobium by PEO COUPLED EPD Process, Surf. Coat. Technol., 2021, 416, p 127161.

D. Madhuri, R. Ghosh, M.A. Hasan, A. Dey, A.M. Pillai, K.S. Anantharaju and A. Rajendra, Development and Characterization of High Emittance and Low-Thickness Plasma Electrolytic Oxidation Coating on Ti6Al4V for Spacecraft Application, J. Mater. Eng. Perform., 2021, 30, p 4072–4082.

J.J. Zhuang, R.G. Song, N. Xiang, Y. Xiong and Q. Hu, Effect of Current Density on Microstructure and Properties of PEO Ceramic Coatings on Magnesium Alloy, Surf. Eng., 2017, 33, p 744–752.

Y.K. Qin, D.S. Xiong, J.L. Li and R. Tyagi, Compositions and Tribological Properties of PEO Coatings on Ti6Al4V Alloy, Surf. Eng., 2017, 33, p 895–902.

C.L. Chang, G.J. Luo, F.C. Yang and J.F. Tang, Effects of Duty Cycle on Microstructure of TiN Coatings Prepared Using CAE/HiPIMS, Vacuum, 2021, 192, p 110449.

L. An, M.A. Ying, X. Yan, W. Sheng and Z. Wang, Effects of Electrical Parameters and their Interactions on Plasma Electrolytic Oxidation Coatings on Aluminum Substrates, Trans. Nonferrous Met. Soc. China., 2020, 30, p 883–895.

R. Bahador, N. Hosseinabadi and A. Yaghtin, Effect of Power Duty Cycle on Plasma Electrolytic Oxidation of A356-Nb2O5 Metal Matrix Composites, J. Mater. Eng. Perform., 2021, 30, p 2586–2604.

N.A. Baseri, M. Mohammadi, M. Ghatee, M.A. Firouzjah and H. Elmkhah, The Effect of Duty Cycle on the Mechanical and Electrochemical Corrosion Properties of Multilayer CrN/CrAlN Coatings Produced by Cathodic Arc Evaporation, Surf. Eng., 2021, 37(2), p 253–262.

Y. Zhao, N. Ye, H. Zhuo, C. Wei, W. Zhou, J. Mao and J. Tang, Influence of Pulse Current Forward-Reverse Duty Cycle on Structure and Performance of Electroplated W-Cu Composite Coatings, Materials, 2021, 14, p 1233.

K. Venkateswarlu, S. Suresh, N. Rameshbabu, A.C. Bose and S. Subramanian, Effect of Electrolyte Chemistry on the Structural, Morphological and Corrosion Characteristics of Titania Films Developed on Ti-6Al-4V Implant Material by Plasma Electrolytic Oxidation, Key Eng. Mater., 2012, 493, p 436–441.

Gh.B. Darband, M. Aliofkhazraei, P. Hamghalam and N. Valizade, Plasma Electrolytic Oxidation of MAGNESIUM and Its Alloys: Mechanism, Properties and Applications, J. Magnes. Alloy., 2017, 5, p 74–132.

A. Saikiran, S. Hariprasad, S. Arun, K.L. Rama and N. Rameshbabu, Effect of Electrolyte Composition on Morphology and Corrosion Resistance of Plasma Electrolytic Oxidation Coatings on Aluminized steel, Surf. Coat. Technol., 2019, 372, p 239–251. https://doi.org/10.1016/j.surfcoat.2019.05.047

J. He, Y. Du, Y. Bai, J. An, X. Cai, Y. Chen and P. Wang, Facile Formation of Anatase/Rutile TiO2 Nanocomposites with Enhanced Photocatalytic Activity, Molecules, 2019, 24, p 2996.

K. He, N. Chen, C. Wang, L. Wei and J. Chen, Method for Determining Crystal Grain Size by x-ray Diffraction, Cryst. Res. Technol., 2018, 53(2), p 1700157. https://doi.org/10.1002/crat.201700157

D.A.H. Hanaor and C.C. Sorrell, Review of the Anatase to Rutile Phase Transformation, J. Mater. Sci., 2011, 46, p 855–874.

M. Rahmati, K. Raeissi, M.R. Toroghinejad, A. Hakimizad and M. Santamaria, Effect of Pulse Current Mode on Microstructure, Composition and Corrosion Performance of the Coatings Produced by Plasma Electrolytic Oxidation on AZ31 Mg Alloy, Coatings, 2019, 9, p 688.

X. Dai, C. Wen, L. Wu, L. Liu, Y. Wu, X. Ding, J. Wu, W. Ci, A. Tang and F. Pan, Influences of Pulse Frequency on Formation and Properties of Composite Anodic Oxide Films on Ti-10V-2Fe-3Al Alloy, Chin. J. Aeronaut., 2021, 34(11), p 228–242.

V. Dehnavi, X.Y. Liu, B.L. Luan, D.W. Shoesmith and S. Rohani, Phase Transformation in Plasma Electrolytic Oxidation Coatings on 6061 Aluminum Alloy, Surf. Coat. Technol., 2014, 251, p 106–114.

S. Parvate, P. Dixit and S. Chattopadhyay, Superhydrophobic Surfaces: Insights from THEORY and Experiment, J. Phys. Chem. B., 2020, 124, p 1323–1360.

M. Sandhyarani, N. Rameshbabu, K. Venkateswarlu and L. Rama-Krishna, Fabrication, Characterization and In-Vitro Evaluation of Nanostructured Zirconia/Hydroxyapatite Composite Film on Zirconium, Surf. Coat. Technol., 2014, 238, p 58–67.

J.Y. Lim, X. Lui, E.A. Vogler and H.J. Donahue, Systematic Variation in Osteoblast Adhesion and Phenotype with Substratum Surface Characteristics, J. Biomed. Mater. Res., 2004, 68A, p 504–512.

E.A. Vogler, Structure and Reactivity of Water at Biomaterial Surfaces, Adv. Colloid Interface Sci., 1998, 74, p 69–117.

Z. Shahri, S.R. Allahkaram, R. Soltani and H. Jafari, Optimisation of Plasma Electrolyte Oxidation Process Parameters for Corrosion Resistance of Mg Alloy, J. Magnes. Alloy., 2020, 8, p 431–440.

R. Ramachandran and M. Nosonovsky, Coupling of Surface Energy with Electric Potential Makes Superhydrophobic Surfaces Corrosion-Resistant, Phys. Chem. Chem. Phys., 2015, 17, p 24988–24997.

Acknowledgments

The author (NRB) would also like to thank and acknowledge the financial support received from the Defence Research & Development Organisation (DRDO), New Delhi (No. EMR/2016/003259 dated 22-03-2017) to carry out this research

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Premchand, C., Lokeshkumar, E., Manojkumar, P. et al. Laser Sintered Ti-6Al-4V Alloy Coated with Plasma Electrolytic Oxidation: Influence of Duty Cycle and Frequency on Morphological, Structural, and Corrosion Properties. J. of Materi Eng and Perform 31, 7955–7963 (2022). https://doi.org/10.1007/s11665-022-06810-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06810-8