Abstract

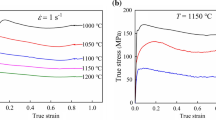

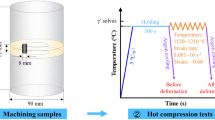

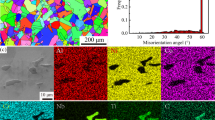

In this work, the microstructure evolution and dynamic recrystallization (DRX) mechanism of double-cone specimens of GH4742 superalloys during hot compression were studied by means of various microtechniques. Two hot deformation regimes are designed and implemented, i.e., γ single-phase region (1080-1100 °C) and γ + γ′ double-phase region (1120-1140 °C). Microstructure analysis shows that coarse carbides (> 1 μm) promote the development of DRX through PSN, and the contribution to recrystallization is more than 5 times that of the fraction of carbides. Moreover, the average recrystallized grain size of PSN is always smaller than the average DRX grain size, and it does not exceed 7 μm and even deforms at a higher temperature of 1140 °C. When deformed in the double-phase region, a large number of fine γ' particles with a diameter less than 0.8 μm hinder DRX. In addition to traditional dynamic recrystallization (DRX), twin recrystallization begins at the initial deformation twin boundary, and necklace recrystallized grains are formed inside the grains.

Similar content being viewed by others

References

W.W. Kong, C. Yuan, B.N. Zhang, H.Y. Qin and G.P. Zhao, Investigation on Low-Cycle Fatigue Behaviors of Wrought Superalloy GH4742 at Room-Temperature and 700 °C, Mater. Sci. Eng. A, 2019, 751, p 226–236.

X.D. Lu, J.H. Du, Q. Deng and Z.Y. Zhong, Effect of Slow Cooling Treatment on Hot Deformation Behavior of GH4742 Superalloy, J. Alloys Compd., 2009, 486, p 195–198.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D. Juul Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen and A.D. Rollett, Current Issues in Recrystallization: A Review, Mater. Sci. Eng. A, 1997, 238, p 219–274.

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura and J.J. Jonas, Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater. Sci., 2014, 60, p 130–207.

A. Dehghan-Manshadi, M.R. Barnett and P.D. Hodgson, Recrystallization in AISI 304 Austenitic Stainless Steel during and After Hot Deformation, Mater. Sci. Eng. A, 2008, 485, p 664–672.

H. Beladi, P. Cizek and P.D. Hodgson, Dynamic Recrystallization of Austenite in Ni-30 Pct Fe Model Alloy: Microstructure and Texture Evolution, Metall. Mater. Trans. A, 2019, 40, p 1175–1189.

S. Gourdet and F. Montheillet, An Experimental Study of the Recrystallization Mechanism during Hot Deformation of Aluminium, Mater. Sci. Eng. A, 2000, 283, p 274–288.

A. Galiyev, R. Kaibyshev and G. Gottstein, Correlation of Plastic Deformation and Dynamic Recrystallization in Magnesium Alloy ZK60, Acta Mater., 2001, 49, p 1199–1207.

S. Gourdet and F. Montheillet, A Model of Continuous Dynamic Recrystallization, Acta Mater., 2003, 51, p 2685–2699.

K. Tsuzaki, X.X. Huang and T. Maki, Mechanism of Dynamic Continuous Recrystallization during Superplastic Deformation in a Microduplex Stainless Steel, Acta Mater., 1996, 44, p 4491–4499.

N.M. Xiao, P. Hodgson, B. Rolfe and D.Z. Li, Modelling Discontinuous Dynamic Recrystallization using a Quantitative Multi-Order-Parameter Phase-Field Method, Comp. Mater. Sci., 2018, 155, p 298–311.

D.K. Guan, W.M. Rainforth, L. Ma, B. Wynne and J.H. Gao, Twin Recrystallization Mechanisms and Exceptional Contribution to Texture Evolution during Annealing in a Magnesium Alloy, Acta Mater., 2017, 126, p 132–144.

A.D. Manshadi, M.R. Barnett and P.D. Hodgson, Hot Deformation and Recrystallization of Austenitic Stainless Steel: Part I. Dynamic Recrystallization, Metall. Mater. Trans. A, 2008, 39, p 1359–1370.

A. Korbel, J.D. Embury, M. Hatherly, P.L. Martin and H.W. Erbsloh, Microstructural Aspects of Strain Localization in Al-Mg Alloys, Acta Metall., 1986, 34, p 1999–2009.

Q.Y. Yu, Z.H. Yao and J.X. Dong, Deformation and Recrystallization Behavior of a Coarse-Grain, Nickel-Base Superalloy Udimet720Li Ingot Material, Mater. Charact., 2015, 107, p 398–410.

O. Sitdikov and R. Kaibyshev, Dynamic Recrystallization in Pure Magnesium, Mater. Trans., 2001, 42, p 1928–1937.

T. Wang, J.J. Jonas and S. Yue, Dynamic Recrystallization Behavior of a Coarse-Grained Mg-2Zn-2Nb Magnesium Alloy, Metall. Mater. Trans. A, 2017, 48, p 594–600.

Q. Ma, B. Li, E.B. Marin and S.J. Horstemeyer, Twinning-Induced Dynamic Recrystallization in a Magnesium Alloy Extruded at 450 °C, Scripta Mater., 2011, 65, p 823–826.

S.W. Xu, S. Kamado, N. Matsumoto, T. Honma and Y. Kojima, Recrystallization Mechanism of As-Cast AZ91 Magnesium Alloy during Hot Compressive Deformation, Mater. Sci. Eng. A, 2009, 527, p 52–60.

H. Yan, S.W. Xu, R.S. Chen, S. Kamado, T. Honma and E.H. Han, Twins, Shear Bands and Recrystallization of a Mg-2.0%Zn-0.8%Gd Alloy during Rolling, Scripta Mater., 2011, 64, p 141–144.

K. Huang, K. Marthinsen, Q.L. Zhao and R.E. Logé, The Double-Edge Effect of Second-Phase Particles on the Recrystallization Behaviour and Associated Mechanical Properties of Metallic Materials, Prog. Mater. Sci., 2018, 92, p 284–359.

A. Belyakov, F.G. Wei, K. Tsuzaki, Y. Kimura and Y. Mishima, Incomplete Recrystallization in Cold Worked Steel Containing TiC, Mater. Sci. Eng. A, 2007, 471, p 50–56.

G. Zhou, H. Ding, F.R. Cao and B.J. Zhang, A comparative Study of Various Flow Instability Criteria in Processing Map of Superalloy GH4742, J. Mater. Sci. Technol., 2014, 30, p 217–222.

H.B. Zhang, H.P. Zhou, S.X. Qin, J. Liu and X.M. Xu, Effect of Deformation Parameters on Twinning Evolution during Hot Deformation in a Typical Nickel-Based Superalloy, Mater. Sci. Eng. A, 2017, 696, p 290–298.

D.G. Brandon, The Structure of High-Angle Boundaries, Acta Metall., 1966, 14, p 1479–1484.

S. Mandal, A.K. Bhaduri and V.S. Sarma, A Study on Microstructural Evolution and Dynamic Recrystallization during Isothermal Deformation of a Ti-Modified Austenitic Stainless Steel, Metall. Mater. Trans. A, 2011, 42, p 1062–1072.

D. Ponge and G. Gottstein, Necklace Formation during Dynamic Recrystallization: Mechanisms and Impact on Flow Behavior, Acta Mater., 1998, 46, p 69–80.

L. Wang, G. Xie, J. Zhang and L.H. Lou, On the Role of Carbides during the Recrystallization of a Directionally Solidified Nickel-Base Superalloy, Scripta Mater., 2006, 55, p 457–460.

Y. Cao, H.S. Di, J.Q. Zhang, J.C. Zhang, T.J. Ma and R.D.K. Misra, An Electron Backscattered Diffraction Study on the Dynamic Recrystallization Behavior of a Nickel-Chromium Alloy (800H) during Hot Deformation, Mater. Sci. Eng. A, 2013, 585, p 71–85.

S.K. Pradhan, S. Mandal, C.N. Athreya, K. Arun Babu, B. de Boer and V. Subramanya Sarma, Influence of Processing Parameters on Dynamic Recrystallization and the Associated Annealing Twin Boundary Evolution in a Nickel Base Superalloy, Mater. Sci. Eng. A, 2017, 700, p 49–58.

D.P. Field, L.T. Bradford, M.M. Nowell and T.M. Lillo, The Role of Annealing Twins during Recrystallization of Cu, Acta Mater., 2007, 55, p 4233–4241.

X.W. Yang, W.Y. Li, J. Ma, S.T. Hu, Y. He, L. Li and B. Xiao, Thermo-Physical Simulation of the Compression Testing for Constitutive Modeling of GH4169 Superalloy during Linear Friction Welding, J. Alloys Compd., 2016, 656, p 385–407.

A. Momeni, K. Dehghani and G.R. Ebrahimi, Modeling the Initiation of Dynamic Recrystallization using a Dynamic Recovery Model, J. Alloys Compd., 2011, 509, p 9387–9393.

J. Humphreys, G.S. Rohrer and A. Rollett, Recrystallization and Related Annealing Phenomena, 3rd ed. Elsevier, Oxford, 2017.

D.G. Cram, H.S. Zurob, Y.J.M. Brechet and C.R. Hutchinson, Modelling Discontinuous Dynamic Recrystallization using a Physically Based Model for Nucleation, Acta Mater., 2009, 57, p 5218–5228.

S.A. Sani, G.R. Ebrahimi and A.R.K. Rashid, Hot Deformation Behavior and Dynamic Recrystallization Kinetics of AZ61 and AZ61 + Sr Magnesium Alloys, J. Magnes. Alloys, 2016, 4, p 104–114.

S. Mahajan, C.S. Pande, M.A. Imam and B.B. Rath, Formation of Annealing Twins in fcc Crystals, Acta Mater, 1997, 45, p 2633–2638.

D.P. Field, L.T. Bradford, M.M. Nowell and T.M. Lillo, The Role of Annealing Twins during Recrystallization of Cu, Acta Mater, 2007, 55, p 4233–4241.

M. Zouari, N. Bozzolo and R.E. Loge, Mean Field Modelling of Dynamic and Post-Dynamic Recrystallization during Hot Deformation of Inconel 718 in the Absence of δ Phase Particles, Mater. Sci. Eng. A, 2016, 655, p 408–424.

S.A. Sania, H. Arabia and G.R. Ebrahimib, Hot Deformation Behavior and DRX Mechanism in a γ-γ′ Cobalt-Based Superalloy, Mater. Sci. Eng. A, 2019, 764, p 138165.

X.Y. Song and M. Rettenmayr, Modeling Recrystallization in a Material Containing Fine and Coarse Particles, Comp. Mater. Sci., 2007, 40, p 234–245.

S.F. Zhang, W.D. Zeng, D.D. Zhou, Y.J. Lai and Q.Y. Zhao, The Particle Stimulated Nucleation in Ti-35V-15Cr-0.3Si-0.1C Alloy, Mater. Lett., 2016, 166, p 317–320.

Y.H. Zhang, D.J. Jensen, Y.B. Zhang, F.X. Lin, Z.Q. Zhang and Q. Liu, Three-Dimensional Investigation of Recrystallization Nucleation in a Particle-Containing Al Alloy, Scripta Mater., 2012, 67, p 320–323.

A. Halfpenny, D.J. Prior and J. Wheeler, Analysis of Dynamic Recrystallization and Nucleation in a Quartzite Mylonite, Tectonophysics, 2006, 427, p 3–14.

J.L. Brimhall, M.J. Klein and R.A. Huggins, Influence of a Finely Dispersed Second Phase on Recrystallization, Acta Metall., 1966, 14, p 459–466.

F.J. Humphreys, Recrystallization Mechanisms in Two-Phase Alloys, Met. Sci., 1979, 13, p 139–145.

X.J. Ye, X.J. Gong, B.B. Yang, Y.P. Li and Y. Nie, Deformation Inhomogeneity Due to Sample-Anvil Friction in Cylindrical Compression Test, Trans. Nonferrous Met. Soc. China, 2019, 29, p 279–286.

H. Miura, T. Sakai, R. Mogawa and G. Gottstein, Nucleation of Dynamic Recrystallization at Grain Boundaries in Copper Bicrystals, Scripta Mater., 2004, 51, p 671–675.

D. Lunt, X. Xu, T. Busolo, J. Quinta da Fonseca and M. Preuss, Quantification of Strain Localisation in a Bimodal Two-Phase Titanium Alloy, Scripta Mater., 2018, 145, p 45–49.

L. Cao, P. Wollgramm, D. Bürger, A. Kostka, G. Cailletaud and G. Eggeler, How Evolving Multiaxial Stress States Affect the Kinetics of Rafting during Creep of Single Crystal Ni-Base Superalloys, Acta Mater., 2018, 158, p 381–392.

M. Kamaraj, Rafting in Single Crystal Nickel-Base Superalloys—An Overview, Sādhanā, 2003, 28, p 115–128.

M. Véron, Y. Bréchet and F. Louchet, Strain Induced Directional Coarsening in Ni Based Superalloys, Scripta Mater., 1996, 34, p 1883–1886.

A. Epishin, T. Link, M. Nazmy, M. Staubli, H. Klingelhöffer and G. Nolze, Microstructural Degradation of CMSX-4: Kinetics and Effect on Mechanical Properties, Superalloys, 2008, 725–731

H.J. Yang, J.H. Zhang, Y.B. Xu and M.A. Meyers, Microstructural Characterization of the Shear Bands in Fe-Cr-Ni Single Crystal by EBSD, J. Mater. Sci. Technol., 2008, 24, p 819–828.

D.J. Badiola, A.I. Mendia and I. Gutiérrez, Evaluation of Intragranular Misorientation Parameters Measured by EBSD in a Hot Worked Austenitic Stainless Steel, J. Microsc., 2007, 228, p 373–383.

M.A. Charpagne, T. Billot, J.M. Franchet and N. Bozzolo, Heteroepitaxial Recrystallization: A New Mechanism Discovered in a Polycrystalline γ-γ′ Nickel Based Superalloy, J. Alloys Compd., 2016, 688, p 685–694.

C. Schafer, J. Song and G. Gottstein, Modeling of Texture Evolution in the Deformation Zone of Second-Phase Particles, Acta Mater., 2009, 57, p 1026–1034.

J.D. Robson, D.T. Henry and B. Davis, Particle Effects on Recrystallization in Magnesium-Manganese Alloys: Particle-Stimulated Nucleation, Acta Mater., 2009, 57, p 2739–2747.

E.I. Galindo-Nava, L.D. Connor and C.M.F. Rae, On the Prediction of the Yield Stress of Unimodal and Multimodal γ′ Nickel-Base Superalloys, Acta Mater., 2015, 98, p 377–390.

S. Poulat, B. Decamps, L. Priester and J. Thibault, Incorporation Processes of Extrinsic Dislocations in Singular, Vicinal and General Grain Boundaries in Nickel, Mater. Sci. Eng. A, 2001, 309–310, p 483–485.

Y. Takayama and J.A. Szpunar, Stored Energy and Taylor Factor Relation in an Al-Mg-Mn Alloy Sheet Worked by Continuous Cyclic Bending, Mater. Trans., 2004, 45, p 2316–2325.

Acknowledgment

This research was supported by the National Science and Technology Major Project (2017-VI-0018-0090).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qin, H., Tian, Q., Zhang, W. et al. Microstructure Evolution of GH4742 Ni-Based Superalloy during Hot Forming. J. of Materi Eng and Perform 31, 5652–5667 (2022). https://doi.org/10.1007/s11665-022-06636-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06636-4