Abstract

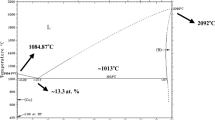

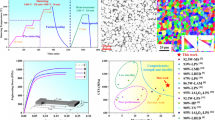

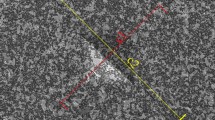

A powder metallurgy-based strategy to in situ construct a three-dimensionally interconnected hexagonal boron nitride (3Di-hBN) layers surrounding the grains of Cu-Ni matrix through metal–organic chemical vapor deposition process was utilized to fabricate 3Di-hBN-reinforced Cu0.7-Ni0.3 (3Di hBN-Cu-Ni) composite. The effect of 3Di-hBN on the mechanical properties of 3Di hBN-Cu-Ni composite was assessed by comparing with pure Cu-Ni alloy (without hBN) fabricated via powder metallurgy route under similar processing conditions. Uniaxial tensile investigations showed that 3Di-hBN positively influenced the mechanical properties of 3Di hBN-Cu-Ni composite; ∼16.3, ∼11.67, and ∼27.9% higher yield strength, UTS, and fracture toughness, respectively, compared to PM Cu-Ni alloy. The overall improved performance of 3Di hBN-Cu-Ni composite was attributed to the formation of 3Di-hBN layers at the interfaces of Cu-Ni grains, which enable the composite to withstand the applied load through the mechanisms of load transfer, dislocation strengthening, and grain refinement. In addition, thermal conductivity of 3Di hBN-Cu-Ni composite was found ∼10% higher than that of pure Cu-Ni alloy.

Similar content being viewed by others

References

A. Ercetin and D.Y. Pimenov, Microstructure, Mechanical, and Corrosion Behavior of Al2O3 Reinforced Mg2Zn Matrix Magnesium Composites, Materials, 2021, 14(17), p 4819.

M. Etaat, H. Pouraliakbar, G. Khalaj and M. Ghambari, Adhesion Strength Measurement of Nickel Layer on the Iron-Based P/M Parts Influenced by Different Surface Pre-Treatment Operations, Measurement, 2015, 66, p 204–211.

J. Zhang, R.J. Perez and E.J. Lavernia, Documentation of Damping Capacity of Metallic, Ceramic and Metal-Matrix Composite Materials, J. Mater. Sci., 1993, 28(9), p 2395–2404.

J.W. Kaczmar, K. Pietrzak and W. Włosiński, The Production and Application of Metal Matrix Composite Materials, J. Mater. Process. Technol., 2000, 106(1), p 58–67.

S.P. Rawal, Metal-Matrix Composites for Space Applications, JOM, 2001, 53(4), p 14–17.

S.K. Moheimani, M. Dadkhah and A. Saboori, Development of Novel AlSi10Mg Based Nanocomposites: Microstructure Thermal and Mechanical Properties, Metals, 2019, 9(9), p 1000.

S. Cai, X. Chen, P. Liu, H. Zhou, S. Fu, K. Xu, S. Chen and D. Liang, Fabrication of Three-Dimensional Graphene/Cu-Ag Composites by In situ Chemical Vapor Deposition and Their Properties, J. Mater. Eng. Perform., 2020, 29(4), p 2248–2255.

Z. Hu, G. Tong, D. Lin, C. Chen, H. Guo, J. Xu and L. Zhou, Graphene-Reinforced Metal Matrix Nanocomposites: A Review, Mater. Sci. Technol., 2016, 32(9), p 930–953.

A.K. Kasar, G. Xiong and P.L. Menezes, Graphene-Reinforced Metal and Polymer Matrix Composites, JOM, 2018, 70(6), p 829–836.

A.S. Wadhwa and A. Chauhan, An Overview of the Controllable Process Parameters in Mechanical Characterization of developed Hybrid Metal Matrix Composites and their Optimization for Advanced Engineering Applications, Mater. Today Proc., 2020, 28, p 1295–1301.

X. Dong, J. Hu, H. Wang, S. Liu and Z. Guo, A Study on Carbon Concentration Distribution and Microstructure of P/M Materials Prepared by Carbusintering, J. Mater. Process. Technol., 2009, 209(8), p 3776–3782.

A. El-Tantawy, W.M. Daoush and A.E. El-Nikhaily, Microstructure and Properties of BN/Ni-Cu Composites Fabricated by Powder Technology, J. Exp. Nanosci., 2018, 13(1), p 174–187.

G. Miranda, P. Ferreira, M. Buciumeanu, A. Cabral, M. Fredel, F.S. Silva and B. Henriques, Microstructure, Mechanical and Wear Behaviors of Hot-Pressed Copper-Nickel-Based Materials for Diamond Cutting Tools, J. Mater. Eng. Perform., 2017, 26(8), p 4046–4055.

Z. Trojanová, K. Dash, K. Máthis, P. Lukáč and A. Kasakewitsch, Elastic and Plastic Behavior of an Ultrafine-Grained Mg Reinforced with BN Nanoparticles, J. Mater. Eng. Perform., 2018, 27(6), p 3112–3121.

A. Ercetin, Ö. Özgün and K. Aslantas, Investigation of Mechanical Properties of Mg5Sn-xZn Alloys Produced Through New Method in Powder Metallurgy, J. Test. Eval., 2021, 49(5), p 20200020.

A. Ercetin, Application of the Hot Press Method to Produce New Mg Alloys: Characterization, Mechanical Properties, and Effect of Al Addition, J. Mater. Eng. Perform., 2021, 30(6), p 4254–4262.

X. Wen and R. Joshi, 2D Materials-Based Metal Matrix Composites, J. Phys. D Appl. Phys, 2020, 53(42), p 423001.

H. Pouraliakbar, A.H. Monazzah, R. Bagheri, S.S. Reihani, G. Khalaj, A. Nazari and M. Jandaghi, Toughness Prediction in Functionally Graded Al6061/SiCp Composites Produced by Roll-Bonding, Ceram. Int., 2014, 40(6), p 8809–8825.

H. Pouraliakbar, A. Nazari, P. Fataei, A.K. Livary and M. Jandaghi, Predicting Charpy Impact Energy of Al6061/SiCp Laminated Nanocomposites in Crack Divider and Crack Arrester Forms, Ceram. Int., 2013, 39(6), p 6099–6106.

J.R. Brockenbrough, S. Suresh and H.A. Wienecke, Deformation of Metal-Matrix Composites with Continuous Fibers: Geometrical Effects of Fiber Distribution and Shape, Acta Metall. Mater., 1991, 39(5), p 735–752.

S. Farahmand, A.H. Monazzah and M.H. Soorgee, The Fabrication of Al2O3-Al FGM by SPS Under Different Sintering Temperatures: Microstructural Evaluation and Bending Behavior, Ceram. Int., 2019, 45(17), p 22775–22782.

K. Chu and C. Jia, Enhanced Strength in Bulk Grapheme-Copper Composites, Physica Status Solidi, 2014, 211(1), p 184–190.

A. Naseer, F. Ahmad, M. Aslam, B.H. Guan, W.S.W. Harun, N. Muhamad, M.R. Raza and R.M. German, A Review of Processing Techniques for Graphene-Reinforced Metal Matrix Composites, Mater. Manuf. Processes, 2019, 34(9), p 957–985.

A.H. Monazzah, H. Pouraliakbar, R. Bagheri and S.M.S. Reihani, Al-Mg-Si/SiC Laminated Composites: Fabrication, Architectural Characteristics, Toughness, Damage Tolerance, Fracture Mechanisms, Compos. B Eng., 2017, 125, p 49–70.

S.-R. Kawk, T.A. Ring and B.-S. Choi, A Simple Two-Step Fabrication Route for Cu Composite Reinforced by Three-Dimensional Graphene Network, J. Ind. Eng. Chem., 2019, 70, p 484–488.

Y. Chen, X. Zhang, E. Liu, C. He, Y. Han, Q. Li, P. Nash and N. Zhao, Fabrication of Three-Dimensional Graphene/Cu Composite by in-situ CVD and its Strengthening Mechanism, J. Alloy. Compd., 2016, 688, p 69–76.

S. Wang, S. Han, G. Xin, J. Lin, R. Wei, J. Lian, K. Sun, X. Zu and Q. Yu, High-Quality Graphene Directly Grown on Cu Nanoparticles for Cu-Graphene Nanocomposites, Mater. Des., 2018, 139, p 181–187.

X. Li, T.A. Ring and B.-S. Choi, Thermal Conductivity of Three-Dimensionally Interconnected Graphene-Networked Cu Composite Fabricated by a Simple Two-Step Process, Korean J. Met. Mater., 2019, 57(8), p 529–534.

Y. Jo, X. Li, D. Cho and B.-S. Choi, Tensile Properties of Three-Dimensionally Interconnected Graphene-Networked Cu Composite and Changes in its Microstructure in Relation to Heat Treatment Temperature, J. Adv. Eng. Technol., 2019, 12(02), p 091–095.

X. Zhang, Y. Xu, M. Wang, E. Liu, N. Zhao, C. Shi, D. Lin, F. Zhu and C. He, A Powder-Metallurgy-Based Strategy Toward Three-Dimensional Graphene-Like Network for Reinforcing Copper Matrix Composites, Nat. Commun., 2020, 11(1), p 1–13.

S. Hu, M. Lozada-Hidalgo, F. Wang, A. Mishchenko, F. Schedin, R. Nair, E. Hill, D. Boukhvalov, M. Katsnelson and R. Dryfe, Proton Transport Through One-Atom-Thick Crystals, Nature, 2014, 516(7530), p 227–230.

S.P. Singh, Effect of Hexa Boron Nitride and REO Addition on Wear and Corrosion Behavior of Hard-Facing on Mild Steel, 2018

T. Natsuki and J. Natsuki, Prediction of Mechanical Properties for Hexagonal Boron Nitride Nanosheets Using Molecular Mechanics model, Appl. Phys. A, 2017, 123(4), p 283.

O.A. Elkady, A. Abu-Oqail, E.M. Ewais and M. El-Sheikh, Physico-Mechanical and Tribological Properties of Cu/h-BN Nanocomposites Synthesized by PM Route, J. Alloy. Compd., 2015, 625, p 309–317.

Z. Liu, Y. Gong, W. Zhou, L. Ma, J. Yu, J.C. Idrobo, J. Jung, A.H. MacDonald, R. Vajtai and J. Lou, Ultrathin High-Temperature Oxidation-Resistant Coatings of Hexagonal Boron Nitride, Nat. Commun., 2013, 4(1), p 1–8.

X. Duan, Z. Yang, L. Chen, Z. Tian, D. Cai, Y. Wang, D. Jia and Y. Zhou, Review on the Properties of Hexagonal Boron Nitride Matrix Composite Ceramics, J. Eur. Ceram. Soc., 2016, 36(15), p 3725–3737.

S. Rathinasabapathy, M. Santhosh, M. Asokan, Significance of Boron Nitride in Composites and Its Applications, Recent Advances in Boron-Containing Materialsed., IntechOpen, 2019.

A.C. Reddy, Study of Factors Influencing Sliding Wear Behavior of Hexagonal Boron Nitride Reinforced AA6061 Metal Matrix Composites, 5th International Conference on Modern Materials and Manufacturing, Bangalore, 2013, pp 409–413.

S. Gopinath, M. Prince and G. Raghav, Enhancing the Mechanical, Wear and Corrosion Behaviour of Stir Casted Aluminium 6061 Hybrid Composites Through the Incorporation of Boron Nitride and Aluminium Oxide Particles, Mater. Res. Exp., 2020, 7(1), p 016582.

X. Li, T.A. Ring and B.-S. Choi, Thermal Conductivity of Three-Dimensionally Interconnected Graphene-Networked Cu Composite Fabricated by a Simple Two-Step Process, Korean J. Metals Mater., 2019, 57(8), p 529–534.

Z. Hussain, H.-W. Yang and B.-S. Choi, Synthesis of Three-Dimensionally Interconnected Hexagonal Boron Nitride Networked Cu-Ni Composite, Korean J. Met. Mater., 2021, 59(7), p 505–513.

M. Parvizi, A. Aladjem and J. Castle, Behaviour of 90-10 Cupronickel in Sea Water, Int. Mater. Rev., 1988, 33(1), p 169–200.

P. Rojas, R. Vera, C. Martínez and M. Villarroel, Effect of the Powder Metallurgy Manufacture Process on the Electrochemical Behaviour of Copper, Nickel and Copper-Nickel Alloys in Hydrochloric Acid, Int. J. Electrochem. Sci, 2016, 11(4701), p e4711.

D. Roylance, Stress-Strain Curves, Massachusetts Institute of Technology study, Cambridge, 2001.

M. Khalaj, S. Zarabi Golkhatmi, S.A.A. Alem, K. Baghchesaraee, M. Hasanzadeh Azar and S. Angizi, Recent Progress in the Study of Thermal Properties and Tribological Behaviors of Hexagonal Boron Nitride-Reinforced Composites, J. Compos. Sci., 2020, 4(3), p 116.

W. Parker, R. Jenkins, C. Butler and G. Abbott, Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity, J. Appl. Phys., 1961, 32(9), p 1679–1684.

X. Hu, T. Björkman, H. Lipsanen, L. Sun and A.V. Krasheninnikov, Solubility of Boron, Carbon, and Nitrogen in Transition Metals: Getting Insight into Trends from First-Principles Calculations, J. Phys. Chem. Lett., 2015, 6(16), p 3263–3268.

T.-A. Chen, C.-P. Chuu, C.-C. Tseng, C.-K. Wen, H.S.P. Wong, S. Pan, R. Li, T.-A. Chao, W.-C. Chueh, Y. Zhang, Q. Fu, B.I. Yakobson, W.-H. Chang and L.-J. Li, Wafer-Scale Single-Crystal Hexagonal Boron Nitride Monolayers on Cu (111), Nature, 2020, 579(7798), p 219–223.

M. Hedayatian, K. Vahedi, A. Nezamabadi and A. Momeni, Microstructural and Mechanical Behavior of Al6061-Graphene Oxide Nanocomposites, Met. Mater. Int., 2020, 26(6), p 760–772.

Y. Chen, X. Zhang, E. Liu, C. He, C. Shi, J. Li, P. Nash and N. Zhao, Fabrication of In-situ Grown Graphene Reinforced Cu Matrix Composites, Sci. Rep., 2016, 6(1), p 1–9.

S.C. Yoo, J. Kim, W. Lee, J.Y. Hwang, H.J. Ryu and S.H. Hong, Enhanced Mechanical Properties of Boron Nitride Nanosheet/Copper Nanocomposites via a Molecular-Level Mixing Process, Compos. Part B Eng., 2020, 195, p 108088.

P. Madhukar, N. Selvaraj, G. Punugupati, G.V. Kumar, C. Rao and S. Mishra, Microstructure Studies of AA7150-hBN Nanocomposites Fabricated by Ultrasonic Assisted Stir Casting, Mater. Res. Exp., 2019, 6(11), p 116545.

W. Yao and L. Fan, Effect of Defects on Mechanical Properties of Novel Hybrid Graphene-h-BN/Copper Layered Nanostructures, Appl. Phys. A, 2019, 125(9), p 663.

D.-B. Xiong, M. Cao, Q. Guo, Z. Tan, G. Fan, Z. Li and D. Zhang, Graphene-and-Copper Artificial Nacre Fabricated by a Preform Impregnation Process: Bioinspired Strategy for Strengthening-Toughening of Metal Matrix Composite, ACS Nano, 2015, 9(7), p 6934–6943.

K. Zhang, Y. Feng, F. Wang, Z. Yang and J. Wang, Two Dimensional Hexagonal Boron Nitride (2D-hBN): Synthesis, Properties and Applications, J. Mater. Chem. C, 2017, 5(46), p 11992–12022.

R. Shu, X. Jiang, W. Liu, Z. Shao, T. Song and Z. Luo, Synergetic Effect of Nano-Carbon and HBN on Microstructure and Mechanical Properties of Cu/Ti3SiC2/C Nanocomposites, Mater. Sci. Eng., A, 2019, 755, p 128–137.

R.E. Smallman and K.H. Westmacott, Stacking Faults in Face-Centred Cubic Metals and Alloys, Philosoph. Mag. J. Theor. Exp. Appl. Phys., 1957, 2(17), p 669–683.

S. Mustapha, M. Ndamitso, A. Abdulkareem, J. Tijani, D. Shuaib, A. Mohammed and A. Sumaila, Comparative Study of Crystallite Size Using Williamson-Hall and Debye-Scherrer Plots for ZnO Nanoparticles, Adv. Natural Sci. Nanosci. Nanotechnol., 2019, 10(4), p 045013.

K. Chu, F. Wang, Y.-B. Li, X.-H. Wang, D.-J. Huang and H. Zhang, Interface Structure and Strengthening Behavior of Graphene/CuCr Composites, Carbon, 2018, 133, p 127–139.

M. Kato, Hall-Petch Relationship and Dislocation Model for Deformation of Ultrafine-Grained and Nanocrystalline Metals, Mater. Trans., 2014, 55(1), p 19–24.

M. Kostecki, T. Cygan, M. Petrus and J. Jaroszewicz, Thermal Properties of Multilayer Graphene and hBN Reinforced Copper Matrix Composites, J. Therm. Anal. Calorim., 2019, 138(6), p 3873–3883.

B. Mortazavi, E.V. Podryabinkin, S. Roche, T. Rabczuk, X. Zhuang and A.V. Shapeev, Machine-Learning Interatomic Potentials enable First-Principles Multiscale Modeling of Lattice Thermal Conductivity in Graphene/Borophene Heterostructures, Mater. Horiz., 2020, 7(9), p 2359–2367.

J.-C. Zheng, L. Zhang, A.V. Kretinin, S.V. Morozov, Y.B. Wang, T. Wang, X. Li, F. Ren, J. Zhang and C.-Y. Lu, High Thermal Conductivity of Hexagonal Boron Nitride Laminates, 2D Mater., 2016, 3(1), p 011004.

H. Shen, C. Cai, J. Guo, Z. Qian, N. Zhao and J. Xu, Fabrication of Oriented hBN Scaffolds for Thermal Interface Materials, RSC Adv., 2016, 6(20), p 16489–16494.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hussain, Z., Jang, H., Choi, H. et al. Microstructure, Mechanical Behavior, and Thermal Conductivity of Three-Dimensionally Interconnected Hexagonal Boron Nitride-Reinforced Cu-Ni Composite. J. of Materi Eng and Perform 31, 2792–2800 (2022). https://doi.org/10.1007/s11665-021-06450-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06450-4