Abstract

The control forging and cooling experiments of H13 and Cr8 die steel were carried out on a MMS-200 thermal simulator. When the cumulative strain of H13 steel reached 2.302 by drawing once, the number of recrystallized grains increased, the recrystallized grains were refined and the corresponding grain grade was about eight. The grain was refined with deformation bands at 750 °C in non-recrystallization region. With increasing cooling rate, the distorted austenite grains evolved into fine recrystallized grains and distorted austenite grains. The microhardness value of annealed H13 steel increased and then decreased with increasing cumulative strain and cooling rate, decreased and then increased with increasing drawing temperature. When the cumulative strain was 1.609 by drawing twice for Cr8 steel, the distribution and quantity of carbide particles were improved. With increasing deformation temperature, the size and number of carbide particles decreased and the dissolution degree increased significantly. Moreover, the intragranular carbide particles dissolved preferentially into matrix. With increasing cooling rate, it presented acicular martensite with granular carbides. The microhardness value of Cr8 decreased first and then increased with increasing cumulative strain and cooling rate, and increased and then decreased with increasing drawing temperature.

Similar content being viewed by others

Reference

N. Sanchez-Mouriño, R. Petrov, J.H. Bae, K. Kim and L.A.I. Kestens, Microstructural Changes after Control Rolling and Interrupted Accelerated Cooling Simulations in Pipeline Steel, Steel Res. Int., 2011, 82(4), p 352–361.

P.C.M. Rodrigues, E.V. Pereloma and D.B. Santos, Mechanical Properities of an HSLA Bainitic Steel Subjected to Controlled Rolling with Accelerated Cooling, Mater. Sci. Eng. A, 2000, 283(1–2), p 136–143.

J.H. Ai, T.C. Zhao, H.J. Gao, Y.H. Hu and X.S. Xie, Effect of Controlled Rolling and Cooling on the Microstructure and Mechanical Properties of 60Si2MnA Spring Steel Rod, J. Mater. Process. Tech., 2005, 160(3), p 390–395.

S. Zhao, D.L. Wei, R.B. Li and L. Zhang, Effect of Cooling Rate on Phase Transformation and Microstructure of Nb–Ti Microalloyed Steel, Mater. Trans., 2014, 55(8), p 1274–1279.

J.C. Herman, Impact of New Rolling and Cooling Technologies on Thermomechanically Processed Steels, Ironmak, Steelmak., 2013, 28(2), p 159–163.

Z. Li, D. Wu and W. Lv, Effects of Rolling and Cooling Conditions on Microstructure and Mechanical Properties of Low Carbon Cold Heading Steel, J. Iron Steel Res. Int., 2012, 19(11), p 64–70.

J. Zhou, D.S. Ma, Y.K. Pei, Z.T. Li, B.S. Liu and S.L. Feng, Influence of Forging Ratio on Microstructure and Impact Property of H13 Hot Work Die Steel by Electrosmelting, Mater. Mech. Eng., 2013, 37(1), p 73–78. ((in Chinese))

Y.K. Pei, D.S. Ma, B.S. Liu, Z.Z. Chen, R. Zhou and J. Zhou, Effect of Forging Ratio on Microstructure and Mechanical Property of H13 Steel, Iron Steel, 2012, 47(2), p 81–86. ((in Chinese))

Y. Wang, C. Liu, F. Jiang, Y.X. Zheng and L.Z. Duan, Influence of Forging Process on the Structure and Impact Property of Electro Remelted H13 Steel, Hebei Metall., 2015, 6, p 5–7. ((in Chinese))

S. He, C.S. Li, J.Y. Ren and Y.H. Han, Investigation on Alloying Element Distribution in Cr8Mo2SiV Cold-Work Die Steel Ingot During Homogenization, Steel Res. Int., 2018, 89, p 1800148.

Y. Xie, G.G. Cheng, X.L. Meng and Y. Huang, Thermal Stability of Primary Elongated V-rich Carbonitrides in H13 Tool Steel. Metall. Res. Technol., 2017, 114(206).

H.G. Fu, X.D. Song, Y.P. Lei, Z.Q. Jiang, J. Yang, J.H. Wang and J.D. Xing, Effect of Homogenization Temperature on Microstructure and Mechanical Properties of Low-Carbon High-Boron Cast Steel, Metals Mater. Int., 2009, 15(3), p 345–352.

S. He, C.S. Li, Y.H. Han and J.Y. Ren, Evolution of the Microstructure and Hardness of Fe-8Cr-2.1Mo-Si-V Die Steel at Different Cooling Rates after Hot Deformation, J. Mater. Eng. Perform., 2019, 28(5), p 4522–4530.

T.V. Pirtovšek, G. Kugler and M. Terčelj, The Behaviour of the Carbides of Ledeburitic AISI D2 Tool Steel During Multiple Hot Deformation Cycles, Mater. Charact., 2013, 83(3), p 97–108.

T.V. Pirtovšek, G. Kugler, M. Godec and M. Terčelj, Microstructural Characterization During the Hot Deformation of 1.17C–11.3Cr-1.48V-2.24W-1.35Mo Ledeburitic Tool Steel, Mater. Charact., 2011, 62(2), p 189–197.

M.R. Ghomashchi and C.M. Sellars, Microstructural Changes in As-cast M2 Grade High Speed Steel During Hot Forging, Metall. Trans. A, 1993, 24A(10), p 2171–2179.

B. Zhou, Y. Shen, J. Chen and Z.S. Cui, Breakdown Behavior of Eutectic Carbide in High Speed Steel During Hot Compression, J. Iron Steel Res. Int., 2011, 18(1), p 41–48.

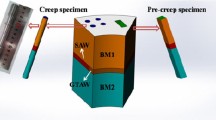

C.S. Li, Y.H. Han, J.Y. Ren, and S. He, An Experimental Method of Controlling Forging and Cooling for Die Steel. Appl. Num. CN202010933147.1.

Y.H. Han, C.S. Li, J.Y. Ren, C.L. Qiu, E. Li and S.S. Chen, Characterization of Hot Deformation Behavior and Processing Map of As-cast H13 Hot Work Die Steel, Metals Mater. Int., 2021, 27, p 3574–3589.

B. Ma, C.S. Li, Y.L. Song, J.K. Wang and F.L. Sui, Deformation and Recrystallization Microtextures of an Austenitic Steel During Asymmetrical Hot Rolling Process, J. Mater. Sci., 2017, 52, p 13212–13226.

L. Vanherpe, N. Moelans, B. Blanpain and S. Vandewalle, Pinning Effect of Spheroid Second-Phase Particles on Grain Growth Studied by Three-Dimensional Phase-Field Simulations, Comput. Mater. Sci., 2010, 49(2), p 340–350.

D. Poddar, P. Cizek, H. Beladi and P.D. Hodgson, Evolution of Strain-Induced Precipitates in a Model Austenitic Fe–30Ni–Nb Steel and Their Effect on the Flow Behaviour, Acta Mater., 2014, 80, p 1–15.

S.M.K. Hosseini, A. Zaeri-Hanzaki and S. Yue, Effect of Austenite Deformation in Non-Recrystallization Region on Microstructure Development in Low-Silicon Content TRIP-Assisted Steels, Mater. Sci. Eng. A, 2014, 618, p 63–70.

M.Y. Sun, Z.Q. Wang, X.M. Wang, C.J. Shang and R.D.K. Misra, The Significant Effect of Non-recrystallization Zone Reduction on Microstructure and Mechanical Properties in Multi-phase Steel from the Perspective of Crystallographic Structure and Variant Pairing, Mater. Sci. Eng. A, 2020, 778, p 139078.

H. Yang, X.G. Zhou, Z.Y. Liu and G.D. Wang, Determination of No-recrystallization Temperature for a Nb-Bearing Steel, J. Wuhan Univ. Technol.-Mat. Sci. Edit., 2016, 31, p 644–647.

S. Jin, N. Tao, K. Marthinsen and Y. Li, Deformation of an Al–7Mg Alloy with Extensive Structural Micro-segregations During Dynamic Plastic Deformation, Mater. Sci. Eng. A, 2015, 628, p 160–167.

Y.H. Han, C.S. Li, J.Y. Ren, C.L. Qiu, Y.Q. Zhang and J.Y. Wang, Dendrite Segregation Changes in High Temperature Homogenization Process of As-cast H13 Steel, ISIJ Int., 2019, 59(10), p 1893–1900.

Y.H. Han, C.S. Li, J.Y. Ren, C.L. Qiu, S.S. Chen and E. Li, Dynamic Recrystallization Behavior During Hot Deformation of As-cast 4Cr5MoSiV1 Steel, J. Mater. Sci., 2021, 56, p 8762–8777.

C.S. Li, S. He, J.Y. Ren and Y.H. Han, The Flow Stress Behavior and Constitutive Model of Cr8Mo2SiV Tool Steel During Hot Deformation, Steel Res. Int., 2021, 92, p 2000434.

A.G. Ning, H.J. Guo, X.C. Chen and X.L. Sun, Precipitation Behaviors of Carbides in H13 Steel During ESR, Forging and Tempering, J. Univ. Sci. Technol. B., 2014, 36(7), p 895–902. ((in Chinese))

R. Alizadeh, R. Mahmudi, A.H.W. Ngan and T.G. Langdon, Microstructural Evolution During Hot Shear Deformation of an Extruded Fine-Grained Mg–Gd–Y–Zr Alloy, J. Mater. Sci., 2017, 52, p 7843–7857.

M. Chapa, S.F. Medina, V. Lopez and B. Fernandez, Influence of Al and Nb on Optimum Ti/N Ratio in Controlling Austenite Grain Growth at Reheating Temperatures, J. Mol. Catal., 2002, 11(1), p 1288–1296.

W.W. Song, Y.A. Min and X.C. Wu, Study on Carbides and Their Evolution in H13 Hot Work Steel, Trans. Mater. Heat Treat., 2009, 30(5), p 122–126.

J. Wang, Z. Xu and X. Lu, Effect of the Quenching and Tempering Temperatures on the Microstructure and Mechanical Properties of H13 Steel, J. Mater. Eng. Perform., 2020, 29(3), p 1849–1859.

Acknowledgments

This work was supported by the National Key Research Project of China (2016YFB0300402).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Han, Y., Li, E. et al. Microstructure and Microhardness of H13 and Cr8 Die Steels in Control Forging and Cooling Process. J. of Materi Eng and Perform 31, 4983–4997 (2022). https://doi.org/10.1007/s11665-021-06303-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06303-0