Abstract

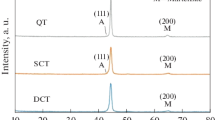

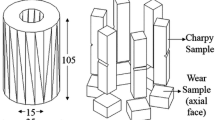

The present study investigated the influence of deep cryogenic treatment (DCT) on the microstructure evolution and wear resistance of Cr12MoV die steel. Four types of heat treatments (quenching + tempering (QT), quenching + DCT (QC), quenching + DCT + tempering (QCT) and quenching + tempering + DCT (QTC)) were utilized to obtain different microstructure and mechanical properties. The hardness, impact toughness, weight loss, frictional coefficient, volume fraction of retained austenite (RA), secondary nanometric carbides (SNC) and worn surface morphology were investigated in detail to discuss the relation between microstructure evolution and wear mechanism changes induced by DCT. The results show that the precipitation of SNC has less effect on hardness than the decrease of carbon content in martensite that caused by DCT and tempering. The principal reason for the high hardness and low toughness without tempering is the high carbon content in martensite. The RA volume fraction has greater effect on the hardness and toughness in condition of tempering. Four types of wear cracks (matrix cracks, boundary cracks, extension cracks and carbide cracks) were identified for the analysis of worn surface morphology. When the matrix hardness is high and RA volume fraction is relatively low, the wear cracks were mainly carbide cracks and extension cracks, accompanied by a few of boundary cracks. When the matrix hardness is low and the RA volume fraction is relatively high, the wear cracks were mainly matrix cracks, accompanied by some boundary cracks and extension cracks. DCT affects the wear mechanism of Cr12MoV die steel by facilitating the transformation of RA and the precipitation of SNC.

Similar content being viewed by others

References

D.N. Korade, K.V. Ramana, K.R. Jagtap and N.B. Dhokey, Effect of Deep Cryogenic Treatment on Tribological Behaviour of D2 Tool Steel—An Experimental Investigation, Mater. Today Proc., 2017, 4, p 7665–7673.

E. Macherauch, Ed, V. Hauk, Ed, Residual stresses in science and technology, Residual stresses in science and technology (1987).

S. Ren, Y. Zhang, Y. Zhao, Z. An, F. Xue, J. Yao, Z. Sun and J. Chang, Enhanced Surface Properties and Microstructure Evolution of Cr12MoV Using Ultrasonic Surface Rolling Process Combined with Deep Cryogenic Treatment, J. Mater. Eng. Perform., 2019, 28, p 1132–1140.

P. Baldissera, C. Delprete, Deep Cryogenic Treatment: A Bibliographic Review. The Open Mechanical Engineering Journal 2 (2008).

H. Li, W. Tong, J. Cui, H. Zhang, L. Chen and L. Zuo, The Influence of Deep Cryogenic Treatment on the Properties of High-Vanadium Alloy Steel, Mater. Sci. Eng. A, 2016, 662, p 356–362.

P.V. Krot, S.V. Bobyr, N.V. Biba, and M.O. Dedik, Modeling of Phase Transformations in the Rolls of the Special Alloy Steels during Quenching and Deep Cryogenic Treatment. In 3rd Mediterranean Conference on Heat Treatment and Surface Engineering (2016).

F.J.D. Silva, S.D. Franco, Á.R. Machado, E.O. Ezugwu and A.M. Souza Jr., Performance of Cryogenically Treated HSS Tools, Wear, 2006, 261, p 674–685.

M.E. Mehtedi, P. Ricci, L. Drudi, S.E. Mohtadi, M. Cabibbo and S. Spigarelli, Analysis of the effect of Deep Cryogenic Treatment on the Hardness and Microstructure of X30 CrMoN 15 1 Steel, Mater. Des., 2012, 33, p 136–144.

S.S. Gill, J. Singh, R. Singh and H. Singh, Effect of Cryogenic Treatment on AISI M2 High Speed Steel: Metallurgical and Mechanical Characterization, J. Mater. Eng. Perform., 2012, 21, p 1320–1326.

A. Molinari, M. Pellizzari, S. Gialanella, G. Straffelini and K.H. Stiasny, Effect of Deep Cryogenic Treatment on the Mechanical Properties of Tool Steels, J. Mater. Process. Technol., 2001, 118, p 350–355.

D. Das, A.K. Dutta and K.K. Ray, Sub-Zero Treatments of AISI D2 Steel: Part I. Microstructure and hardness, Mater. Sci. Eng. A, 2010, 527, p 2182–2193.

D. Das, A.K. Dutta and K.K. Ray, Sub-Zero Treatments of AISI D2 Steel: Part II. Wear Behavior, Mater. Sci. Eng. A, 2010, 527, p 2194–2206.

A.K. Dutta, On the Refinement of Carbide Precipitates by Cryotreatment in AISI D2 Steel, Philos. Mag., 2009, 89, p 55–76.

A. Bensely, D. Senthilkumar, D.M. Lal, G. Nagarajan and A. Rajadurai, Effect of Cryogenic Treatment on Tensile Behavior of Case Carburized Steel-815M17, Mater. Charact., 2007, 58, p 485–491.

S. Zhirafar, A. Rezaeian and M. Pugh, Effect of Cryogenic Treatment on the Mechanical Properties of 4040 Steel, J. Mater. Process Technol., 2007, 186(1–3), p 298–303.

K. Sanjeev, S. Rakesh, and S. Vishal, Wear behavior of differently cryogenically treated AISI H13 steel against cold work steel, in ARCHIVE Proceedings of the Institution of Mechanical Engineers Part E Journal of Process Mechanical Engineering 1989–1996 (2018) 095440891878162.

M.J. Klug, P.J. Klug, T. Kranjec and B. Podgornik, Cross-effect of Surface Finishing and Deep Cryogenic Treatment on Corrosion Resistance of AISI M35 steel, J. Mater. Res. Technol., 2021, 14, p 2365–2381.

P. Jovievi-Klug, T. Kranjec, M. Jovievi-Klug, T. Kosec and B. Podgornik, Influence of the Deep Cryogenic Treatment on AISI 52100 and AISI D3 Steel’s Corrosion Resistance, Materials, 2021, 14, p 6357.

E. Bartolomé, B. Bozzo, P. Sevilla, O. Martínez-Pasarell and T. Puig, ABS 3D Printed Solutions for Cryogenic Applications, Cryogenics, 2017, 80, p 32–37.

P. Jurči, M. Dománková, J. Ptačinová, M. Pašák, M. Kusý and P. Priknerová, Investigation of the Microstructural Changes and Hardness Variations of Sub-Zero Treated Cr-V Ledeburitic Tool Steel Due to the Tempering Treatment, J. Mater. Eng. Perform., 2018, 27, p 1514–1529.

P. Biswas, S. Ghosh, A. Sarkar and N.G. Roy, Investigation of Deep Cryogenic Treatment of Steels for Medical Tooling Applications, J. Phys. Conf. Ser., 2021, 1797, p 012057.

P. Jovievi-Klug and B. Podgornik, Review on the Effect of Deep Cryogenic Treatment of Metallic Materials in Automotive Applications, Met Open Access Metall J, 2020, 10, p 434.

S. Kalia, Cryogenic Processing: A Study of Materials at Low Temperatures, J. Low Temp. Phys., 2010, 158, p 934–945.

M. Villa, and M.A.J. Somers, Cryogenic treatment of steel: from concept to metallurgical understanding, in 24th IFHTSE Congress 2017 European Conference on Heat Treatment and Surface Engineering A3TS Congress (2017).

V.G. Gavriljuk, W. Theisen, V.V. Sirosh, E.V. Polshin, A. Kortmann, G.S. Mogilny, Y.N. Petrov and Y.V. Tarusin, Low-Temperature Martensitic Transformation in Tool Steels in Relation to Their Deep Cryogenic Treatment, Acta Mater., 2013, 61, p 1705–1715.

M.A. Jaswin and D.M. Lal, Effect of Cryogenic Treatment on Corrosion Resistance and Thermal Expansion of Valve Steels, Int. J. Eng. Technol. Manag. Appl. Sci., 2015, 3, p 2349–4476.

P. Jovičević-Klug, L. Tegg, M. Jovičević-Klug, R. Parmar, M. Amati, L. Gregoratti, L. Almásy, J.M. Cairney and B. Podgornik, Understanding Carbide Evolution and Surface Chemistry During Deep Cryogenic Treatment in High-Alloyed Ferrous Alloy, Appl. Surf. Sci., 2023, 610, p 155497.

P. Jovievi-Klug, M. Jovievi-Klug and B. Podgornik, Effectiveness of Deep Cryogenic Treatment on Carbide Precipitation, J. Market. Res., 2020, 9, p 13014–13026.

P. Jovičević-Klug, M. Jovičević-Klug, T. Sever, D. Feizpour and B. Podgornik, Impact of Steel Type, Composition and Heat Treatment Parameters on Effectiveness of Deep Cryogenic Treatment, J. Mater. Res. Technol., 2021, 14, p 1007–1020.

M. Villa and M.A.J. Somers, Cryogenic Treatment of an AISI D2 Steel: The Role of Isothermal Martensite Formation and “Martensite Conditioning,” Cryogenics, 2020, 110, p 103131.

P. Jovičević-Klug, M. Jenko, M. Jovičević-Klug, B.Š Batič, J. Kovač and B. Podgornik, Effect of Deep Cryogenic Treatment on Surface Chemistry and Microstructure of Selected High-Speed Steels, Appl. Surf. Sci., 2021, 548, p 149257.

J.Y. Huang, Y.T. Zhu, X.Z. Liao, I.J. Beyerlein, M.A. Bourke and T.E. Mitchell, Microstructure of Cryogenic Treated M2 Tool Steel, Mater. Sci. Eng. A, 2003, 339, p 241–244.

P. Jovičević-Klug, M. Jovičević-Klug and B. Podgornik, Unravelling the Role of Nitrogen in Surface Chemistry and Oxidation Evolution of Deep Cryogenic Treated High-Alloyed Ferrous Alloy, Coatings, 2022, 12, p 213.

K. Amini, S. Nategh and A. Shafyei, Influence of Different Cryotreatments on Tribological Behavior of 80CrMo12 5 Cold Work Tool Steel, Mater. Des., 2010, 31, p 4666–4675.

A.I. Tyshchenko, W. Theisen, A. Oppenkowski, S. Siebert, O.N. Razumov, A.P. Skoblik, V.A. Sirosh, Y.N. Petrov and V.G. Gavriljuk, Low-Temperature Martensitic Transformation and Deep Cryogenic Treatment of a Tool Steel, Mater. Sci. Eng. A, 2010, 527, p 7027–7039.

S.M. Teus, V.F. Mazanko, J.M. Olive and V.G. Gavriljuk, Grain Boundary Migration of Substitutional and Interstitial Atoms in α-iron, Acta Mater., 2014, 69, p 105–113.

B.K. Anil Kumar, M.G. Ananthaprasad, and K. Gopalakrishna, Action of Cryogenic chill on Mechanical properties of Nickel alloy Metal Matrix Composites, In Materials Science and Engineering Conference Series pp. 012116 (2016).

V.G. Gavriljuk, W. Theisen, V.V. Sirosh, E.V. Polshin, A. Kortmann, G.S. Mogilny, Y.N. Petrov and Y.V. Tarusin, Low-temperature Martensitic Transformation in Tool Steels in Relation to Their Deep Cryogenic Treatment, Acta Mater., 2013, 61, p 1705–1715.

A. Antony, N.M. Schmerl, A. Sokolova, R. Mahjoub, D. Fabijanic and N.E. Stanford, Quantification of the Dislocation Density, Size, and Volume Fraction of Precipitates in Deep Cryogenically Treated Martensitic Steels, Met. Open Access Metall. J., 2020, 10, p 1561.

S. Akncolu, Investigation of the Effect of Deep Cryogenic Process on the Tribological Properties of X153CrMoV12 Mold Steel, J. Mater. Eng. Perform., 2021, 30, p 2843–2852.

R. Gecu, Combined Effects of Cryogenic Treatment and Tempering on Microstructural and Tribological Features of AISI H13 Steel, Mater. Chem. Phys., 2022, 292, p 126802.

L. Han, Y. Wang, S. Liu, Z. Zhang, X. Song, Y. Li, W. Liu, Z. Yang and M. Mu, Effect of Cryogenic Treatment on the Microstructure and Mechanical Properties of Selected Laser Melted H13 Steel, J. Market. Res., 2022, 21, p 5056–5065.

N.B. Dhokey, S.S. Maske and P. Ghosh, Effect of Tempering and Cryogenic Treatment on Wear and Mechanical Properties of Hot Work Tool Steel (H13), Mater. Today Proc., 2021, 43, p 3006–3013.

S. Katoch, R. Sehgal, V. Singh, M.K. Gupta, M. Mia and C.I. Pruncu, Improvement of Tribological Behavior of H-13 Steel by Optimizing the Cryogenic-Treatment Process Using Evolutionary Algorithms, Tribol. Int., 2019, 140, p 105895.

B.A. Mokarian, K. Ghayour and H. Gharavi, The Combined Effect of Cryogenic and Boronising Treatments on the Wear Behaviour and Microstructure of DIN 1.2344 Steel, Trans. Inst. Met. Finish. Int. J. Surf. Eng. Coat., 2019, 97, p 121–128.

M. Koneshlou, K.M. Asl and F. Khomamizadeh, Effect of Cryogenic Treatment on Microstructure, Mechanical and Wear Behaviors of AISI H13 Hot Work Tool Steel, Cryogenics, 2011, 51, p 55–61.

E. Yildiz and S.Y. Tong, Investigation of the Effects of Deep Cryogenic Treatment on the Microstructure, Hardness, Strength and Wear Resistance of X17CrNi16-2 Martensitic Stainless Steel, Surf. Rev. Lett., 2023, 30, p 1–9.

R. Colaço and R. Vilar, Stabilisation of Retained Austenite in Laser Surface Melted Tool Steels, Mater. Sci. Eng. A, 2004, 385, p 123–127.

M. Villa, K. Pantleon and M.A. Somers, Evolution of Compressive Strains in Retained Austenite During Sub-Zero Celsius Martensite Formation and Tempering, Acta Mater., 2014, 65, p 383–392.

A. Bensely, S. Venkatesh, D.M. Lal, G. Nagarajan, A. Rajadurai and K. Junik, Effect of Cryogenic Treatment on Distribution of Residual Stress in Case Carburized En 353 Steel, Mater. Sci. Eng. A, 2008, 479, p 229–235.

M. Preciado and M. Pellizzari, Influence of Deep Cryogenic Treatment on the Thermal Decomposition of Fe-C Martensite, J. Mater. Sci., 2014, 49, p 8183–8191.

S. Li, Y. Xie and X. Wu, Hardness and Toughness Investigations of Deep Cryogenic Treated Cold Work Die Steel, Cryogenics, 2010, 50, p 89–92.

Z. Weng, K. Gu, J. Zheng, C. Cui, M. Zhang and J. Wang, Cryogenically Martensitic Transformation and Its Effects on Tempering Behaviors of Bearing Steel, Mater. Charact., 2022, 190, p 112066.

K. Amini, A. Akhbarizadeh and S. Javadpour, Effect of Deep Cryogenic Treatment on the Formation of Nano-Sized Carbides and the Wear Behavior of D2 Tool Steel, Int. J. Miner. Metall. Mater., 2012, 19, p 5.

P.F.D.S. Farina, C.A. Barbosa, and H. Goldenstein, Microstructural Characterization of an AISI D2 Tool Steel Submitted to Cryogenic Treatment, in 18th International IFHTSE Congress (2010).

D. Senthilkumar, I. Rajendran, M. Pellizzari and J. Siiriainen, Influence of Shallow and Deep Cryogenic Treatment on the Residual State of Stress of 4140 Steel, J. Mater. Process. Technol., 2011, 211, p 396–401.

K. Amini, A. Akhbarizadeh and S. Javadpour, Investigating the Effect of Holding Duration on the Microstructure of 1.2080 Tool Steel During the Deep Cryogenic Heat Treatment, Vacuum, 2012, 86, p 1534–1540.

Y. Dong, X.P. Lin and H.S. Xiao, Deep Cryogenic Treatment of High-Speed Steel and Its Mechanism, Heat Treat. Met., 1998, 25, p 55–59.

F. Meng, K. Tagashira, R. Azuma and H. Sohma, Role of Eta-Carbide Precipitations in the Wear Resistance Improvements of Fe-12Cr-Mo-V-14C Tool Steel by Cryogenic Treatment, Isij Int., 1994, 34, p 205–210.

P. Jovicevic-Klug, M. Jovicevic-Klug, L. Thormahlen, J. Mccord, M. Rohwerder, M. Godec and B. Podgornik, Austenite Reversion Suppression with Deep Cryogenic Treatment: A Novel Pathway Towards 3rd Generation Advanced High-Strength Steels, Mater. Sci. Eng. A Struct. Mater. Prop. Misrostruct. Process., 2023, 837, p 145033.

S.S. Xu, Y. Zhao, D. Chen, L.W. Sun, L. Chen, X. Tong, C.T. Liu and Z.W. Zhang, Nanoscale Precipitation and Its Influence on Strengthening Mechanisms in an Ultra-High Strength Low-Carbon Steel, Pergamon, 2019, 13, p 99–110.

O. Bouaziz and Y. Bréchet, Physical Relationship Between Mean-Field Micro-Mechanical Approach and Orowan Looping in Particle-Strengthened Materials, Scr. Mater., 2009, 60, p 366–368.

S. Jiang, H. Wang, Y. Wu, X. Liu, H. Chen, M. Yao, B. Gault, D. Ponge, D. Raabe, A. Hirata and M. Chen, Ultrastrong Steel Via Minimal Lattice Misfit and High-Density Nanoprecipitation, Nature, 2017, 544, p 460–464.

Z.W. Zhang, C.T. Liu, Y.R. Wen, A. Hirata, S. Guo, G. Chen, M.W. Chen and B.A. Chin, Influence of Aging and Thermomechanical Treatments on the Mechanical Properties of a Nanocluster-Strengthened Ferritic Steel, Metall. and Mater. Trans. A., 2012, 43, p 351–359.

M. Hunkel, Tempering Effects of Athermal Martensite During Quenching and Reheating of a SAE 52100 Bearing Steel, Mater. Sci. Eng. Struct. Mater. Prop. Misrostruct. Process., 2020, 790, p 139.

D.N. Korade, K.V. Ramana and K.R. Jagtap, Study of Effect of Population Density of Carbides on Surface Roughness and Wear Rate of H21 Tool Steel – ScienceDirect, Mater. Today Proc., 2019, 19, p 228–232.

D. Kakas, B. Skoric, S. Mitrovic, M. Babic and M. Vilotic, Influence of Load and Sliding Speed on Friction Coefficient of IBAD Deposited TiN, Tribol. Ind., 2009, 31, p 3–10.

X.H. Cui, S.Q. Wang, M.X. Wei and Z.R. Yang, Wear Characteristics and Mechanisms of H13 Steel with Various Tempered Structures, J. Mater. Eng. Perform., 2011, 19, p 1055–1062.

S.J. Gobbi, V.J. Gobbi, G. Reinke, P.V. Muterlle and D.M. Rosa, Ultra-Low-Temperature Process Effects on Microscale Abrasion of Tool Steel AISI D2, Mater. Sci. Technol., 2019, 35, p 1355–1364.

S. Kumar, M. Nagraj, A. Bongale and N. Khedkar, Deep Cryogenic Treatment of AISI M2 Tool Steel and Optimisation of Its Wear Characteristics Using Taguchi’s Approach, Arab. J. Sci. Eng., 2018, 43, p 4917–4929.

T. Shinde, C. Pruncu, N.B. Dhokey, A.C. Parau and A. Vladescu, Effect of Deep Cryogenic Treatment on Corrosion Behavior of AISI H13 Die Steel, Materials, 2021, 14, p 7863.

R. Thakurai, H. Patle, B.R. Sunil and R. Dumpala, Effect of Cryogenic Treatment Duration on the Microhardness and Tribological Behavior of 40CrMoV5 Tool Steel, Mater. Today Proc., 2020, 38, p 2140–2144.

T. Shinde, Influence of Carbide Particle Size on the Wear Performance of Cryogenically Treated H13 Die Steel, Surf. Eng., 2020, 37, p 1206–1214.

Z. Jiang, L.A. Gyurova, A.K. Schlarb, K. Friedrich and Z. Zhang, Study on Friction and Wear Behavior of Polyphenylene Sulfide Composites Reinforced by Short Carbon Fibers and Sub-micro TiO2 Particles, Compos. Sci. Technol., 2008, 68, p 734–742.

D. Felhs, J. Kargerkocsis, M.J. Churruca, P.M. Frontini and V. Pettarin, Changes in Tribological Performance of High Molecular Weight High Density Polyethylene Induced by the Addition of Molybdenum Disulphide Particles, Wear, 2010, 269, p 31–45.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, C., Li, J., Zhang, Y. et al. Understanding of the Microstructure Evolution and Wear Resistance of Cr12MoV Die Steel during Deep Cryogenic Treatment. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09270-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09270-4