Abstract

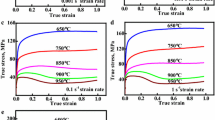

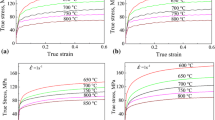

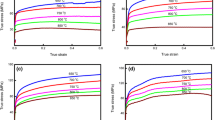

Hot compression tests were performed in the temperature and strain rate range of 700-900 °C and 0.001-10 s−1, respectively, to study the hot deformation behavior and further generate the constitutive equation and a processing map of the Cu-Cr-Nb-Zr alloy. The apparent activation energy for hot deformation was determined as 404±17 kJ mol−1 using Arrhenius type hyperbolic-sine equation. Possible reason for high activation energy was analyzed and the active deformation mechanism during hot deformation was further suggested. Constitutive equation was formulated to predict the flow stress. Dynamic material model was employed to generate the processing map and it was correlated with microstructural examination of the hot compressed specimens. Based on the microstructural observations, the optimum safe hot working parameters for Cu-Cr-Nb-Zr alloy were identified as 880-900°C/10-2 to 100.5 s-1 and 800-875 °C/100.5-101 s−1. The hot working parameters in the safe region were applied to the forging process and results agreed well with the processing map.

Similar content being viewed by others

References

H.C. Groh, D.L. Ellis, and W.S. Loewenthal, Comparison of GRCop-84 to Other Cu Alloys with High Thermal Conductivities, J. Mater. Eng. Perform., 2007, 17(4), p 594–606. https://doi.org/10.1007/s11665-007-9175-3

G. Li, B.G. Thomas, and J.F. Stubbins, Modeling Creep and Fatigue of Copper Alloys, Metall. Mater. Trans. A, 2000, 31(10), p 2491–2502.

X. Guo, Z. Xiao, W. Qiu, Z. Li, Z. Zhao, X. Wang, and Y. Jiang, Microstructure and Properties of Cu-Cr-Nb Alloy with High Strength, High Electrical Conductivity and Good Softening Resistance Performance at Elevated Temperature, Mater. Sci. Eng. A., 2019, 749, p 281–290. https://doi.org/10.1016/j.msea.2019.02.036

G.J. Butterworth and C.B.A. Forty, Review Article A Survey of the Properties Reactor Materials of Copper Alloys for Use as Fusion, J. Nucl. Mater., 1992, 189, p 237–276.

S.A. Lockyer and F.W. Noble, Precipitate Structure in a Cu-Ni-Si Alloy, J. Mater. Sci., 1994, 29(1), p 218–226.

K.R. Anderson, J.R. Groza, R.L. Dreshfield, and D. Ellis, High-Performance Dispersion-Strengthened Cu-8 Cr-4 Nb Alloy, Metall. Mater. Trans. A, 1995, 26(9), p 2197–2206.

K.R. Anderson, J.R. Groza, R.L. Dreshfield, and D. Ellis, Microstructural Evolution and Thermal Stability of Precipitation-Strengthened Cu8Cr4Nb Alloy, Mater. Sci. Eng. A, 1993, 169(1–2), p 167–175.

R.D.K. Misra and V.S. Prasad, On the Dynamic Embrittlement of Copper-Chromium Alloys by Sulphur, J. Mater. Sci., 2000, 35, p 3321–3325. https://doi.org/10.1023/A:1004839825660

S.C. Krishna, K.V. Radhika, K.T. Tharian, M.S. Kiranmayee, G.S Rao, A.K. Jha, and B. Pant, Dynamic Embrittlement in Cu-Cr-Zr-Ti Alloy: Evidence of Intergranular Segregation of Sulphur, J. Mater. Eng. Perform., 2013, 22(8), p 2331–2336.

R.D.K. Misra, V.S. Prasad, and P.R. Rao, Dynamic Embrittlement in an Age-Hardenable Copper-Chromium Alloy, Scr. Mater., 1996, 35(1), p 129–133. https://doi.org/10.1016/1359-6462(96)00098-X

Y. Yang, L. Wang, L. Snead, and S.J. Zinkle, Development of Novel Cu-Cr-Nb-Zr Alloys with the Aid of Computational Thermodynamics, Mater. Des., 2018, 156, p 370–380. https://doi.org/10.1016/j.matdes.2018.07.003

A.K. Shukla, S.V.S.N. Murty, R.S. Kumar, and K. Mondal, Spark Plasma Sintering of Dispersion Hardened Cu-Cr-Nb Alloy Powders, J. Alloys Compd., 2013, 577, p 70–78. https://doi.org/10.1016/j.jallcom.2013.04.088

Y.V.R.K. Prasad, K.P. Rao, and S. Sasidhara, “Hot Working Guide.,” 2015

W. Bao, L. Bao, D. Liu, D. Qu, Z. Kong, M. Peng, and Y. Duan, Constitutive Equations, Processing Maps, and Microstructures of Pb-Mg-Al-B-0.4Y Alloy under Hot Compression, J. Mater. Eng. Perform., 2020, 29(1), p 607–619. https://doi.org/10.1007/s11665-019-04544-8

Y. Duan, L. Ma, H. Qi, R. Li, and P. Li, Developed Constitutive Models, Processing Maps and Microstructural Evolution of Pb-Mg-10Al-0.5B Alloy, Mater. Charact., 2017, 129, p 353–366. https://doi.org/10.1016/j.matchar.2017.05.026

Y. Liu, C. Geng, Q. Lin, Y. Xiao, J. Xu, and W. Kang, Study on Hot Deformation Behavior and Intrinsic Workability of 6063 Aluminum Alloys Using 3D Processing Map, J. Alloys Compd., 2017, 713, p 212–221. https://doi.org/10.1016/j.jallcom.2017.04.156

N. Srinivasa and Y.V.R.K. Prasad, Hot Working Characteristics of Nimonic 75, 80A and 90 Superalloys: A Comparison Using Processing Maps, J. Mater. Process. Tech., 1995, 51(1–4), p 171–192.

H. Wu, S.P. Wen, H. Huang, K.Y. Gao, X.L. Wu, W. Wang, and Z.R. Nie, Hot Deformation Behavior and Processing Map of a New Type Al-Zn-Mg-Er-Zr Alloy, J. Alloys Compd., 2016, 685, p 869–880.

A. Kuper, H. Letaw, L. Slifkin, E. Sonder, and C.T. Tomizuka, Self-diffusion in Copper, Phys. Rev., 1954, 96(5), p 1224–1225. https://doi.org/10.1103/PhysRev.96.1224

J.R. Davis, Copper and Copper Alloys, ASM international, Almere, 2001.

M.J. Morgan, N.T. Switzner, C.W.S. Marchi, and D.K. Balch, Forging Strain Rate and Deformation Temperature Effects on the Fracture Toughness Properties of Type Stainless Steel Precharged with Tritium, Sandia National Lab. (SNL-NM), Albuquerque, 2017.

Y.V.R.K. Prasad and K.P. Rao, Processing Maps and Rate Controlling Mechanisms of Hot Deformation of Electrolytic Tough Pitch Copper in the Temperature Range 300–950 °C, Mater. Sci. Eng. A, 2005, 391(1–2), p 141–150.

L. Zhang, K.X. Song, Y.M. Zhang, Q. Wang, and W.F. Liu, Flow Stress Constitutive Equation of Age Hardening Cu-1.1Cr Alloy during Hot Compression Deformation, Adv. Mater. Res., 2011, 213, p 623–627.

G. Ji, Q. Li, K. Ding, L. Yang, and L. Li, A Physically-Based Constitutive Model for High Temperature Deformation of Cu-0.36Cr-0.03Zr Alloy, J. Alloys Compd, 2015, 648, p 397–407. https://doi.org/10.1016/j.jallcom.2015.06.264

A.K. Shukla, S.V.S.N. Murty, S.C. Sharma, and K. Mondal, Constitutive Modeling of Hot Deformation Behavior of Vacuum Hot Pressed Cu-8Cr-4Nb Alloy, Mater. Des., 2015, 75, p 57–64. https://doi.org/10.1016/j.matdes.2015.03.023

Y. Zhang, Z. Chai, A.A. Volinsky, H.L. Sun, B.H. Tian, P. Liu, and Y. Liu, Hot Deformation Characteristics and Processing Maps of the Cu-Cr-Zr-Ag Alloy, J. Mater. Eng. Perform., 2016, 25(3), p 1191–1198.

Z. Ding, S. Jia, P. Zhao, M. Deng, and K. Song, Hot Deformation Behavior of Cu-0.6Cr-0.03Zr Alloy during Compression at Elevated Temperatures, Mater. Sci. Eng. A, 2013, 570, p 87–91. https://doi.org/10.1016/j.msea.2013.01.059

Y. Zhang, H. Sun, A.A. Volinsky, B. Tian, K. Song, Z. Chai, P. Liu, and Y. Liu, Dynamic Recrystallization Behavior and Processing Map of the Cu–Cr–Zr–Nd Alloy, Springerplus, 2016 https://doi.org/10.1186/s40064-016-2317-z

Y. Zhang, Z. Chai, A.A. Volinsky, B. Tian, H. Sun, P. Liu, and Y. Liu, Processing Maps for the Cu-Cr-Zr-Y Alloy Hot Deformation Behavior, Mater. Sci. Eng. A, 2016, 662, p 320–329. https://doi.org/10.1016/j.msea.2016.03.033

Y. Zhang, A.A. Volinsky, H.T. Tran, Z. Chai, P. Liu, and B. Tian, Effects of Ce Addition on High Temperature Deformation Behavior of Cu-Cr-Zr Alloys, J. Mater. Eng. Perform., 2015, 24(10), p 3783–3788.

P. Zhang, C. Hu, Q. Zhu, C. Ding, and H. Qin, Hot Compression Deformation and Constitutive Modeling of GH4698 Alloy, Mater. Des., 2015, 65, p 1153–1160.

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Metall, 1966, 14(9), p 1136–1138.

C. Zener and J.H. Hollomon, Effect of Strain Rate upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32.

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman, and D.L. Chen, Effect of Zr, v and Ti on Hot Compression Behavior of the Al-Si Cast Alloy for Powertrain Applications, J. Alloys Compd., 2014, 615, p 1019–1031. https://doi.org/10.1016/j.jallcom.2014.06.210

J.Y. Yang and W.J. Kim, The Effect of Addition of Sn to Copper on Hot Compressive Deformation Mechanisms, Microstructural Evolution and Processing Maps, J. Mater. Res. Technol., 2020, 9(1), p 749–761. https://doi.org/10.1016/j.jmrt.2019.11.015

W.V. Youdelis and H.Y. Wu, Interdiffusion in Copper(Rich)-Chromium Solid Solutions, Can. Metall. Q., 1975, 14(4), p 315–318.

D.B. Butrymowicz, J.R. Manning, and M.E. Read, Diffusion in Copper and Copper Alloys Part V. Diffusion in Systems Involving Elements of Group VA, J. Phys. Chem. Ref. Data, 1977, 6(1), p 1–50.

N. Jin, H. Zhang, Y. Han, W. Wu, and J. Chen, Hot Deformation Behavior of 7150 Aluminum Alloy during Compression at Elevated Temperature, Mater. Charact., 2009, 60(6), p 530–536. https://doi.org/10.1016/j.matchar.2008.12.012

M.J. Luton and C.M. Sellars, Dynamic Recrystallization in Nickel and Nickel-Iron Alloys during High Temperature Deformation, Acta Metall., 1969, 17(8), p 1033–1043.

D. Padmavardhani and Y.V.R.K. Prasad, Effect of Zinc Content on the Processing Map for Hot Working of α Brass, Mater. Sci. Eng. A, 1992, 157(1), p 43–51.

R.R. Bourassa and B. Lengeler, The Formation and Migration Energies of Vacancies in Quenched Copper, J. Phys. F Met. Phys., 1976, 6(8), p 1405–1413.

E. Diagram, The Cr-Cu (Chromium-Copper) System, Bull. Alloy Phase Diagr., 1984, 5(1), p 59–68.

D.J. Chakrabarti, The Cu-Nb (Copper-Nloblum) System, Phys. Rev. B, 1979, 29, p 133787.

G. Zhou, H. Ding, F. Cao, and B. Zhang, A Comparative Study of Various Flow Instability Criteria in Processing Map of Superalloy GH4742, J. Mater. Sci. Technol., 2014, 30, p 217–222.

Y.V.R.K. Prasad, Processing Maps: A Status Report, J. Mater. Eng. Perform., 2013, 22(10), p 2867–2874.

S. Murty, B.N. Rao, and B.P. Kashyap, Instability Criteria for Hot Deformation of Materials, Int. Mater. Rev., 2000, 45(1), p 15–26.

S. Ugender, A. Kumar, and A.S. Reddy, Microstructure and Mechanical Properties of AZ31B Magnesium Alloy by Friction Stir Welding, Proced. Mater. Sci., 2014, 6, p 1600–1609. https://doi.org/10.1016/j.mspro.2014.07.143

Y.V.R.K. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43(6), p 243–258. https://doi.org/10.1179/imr.1998.43.6.243

R. Kaibyshev, T. Sakai, H. Miura, J.J. Jonas, and A. Belyakov, Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater. Sci., 2013, 60, p 130–207. https://doi.org/10.1016/j.pmatsci.2013.09.002

N. Ravichandran and Y.V.R.K. Prasad, Influence of Oxygen on Dynamic Recrystallization during Hot Working of Polycrystalline Copper, Mater. Sci. Eng. A, 1992, 156(2), p 195–204.

Z. Xue, L. Gu, Y. Ren, X. Hao, and P. Xu, Deformation Behavior and Processing Parameters of Cu-3Ag-0.6Zr Alloy during Compression at Elevated Temperatures, MATEC Web Conf., 2016, 67, p 03031.

M.H. Wang, Y.C. Yang, S.L. Tu, and K. Wei, A Modified Constitutive Model and Hot Compression Instability Behavior of Cu-Ag Alloy, Trans. Nonferrous Met. Soc. China, 2019, 29(4), p 764–774. https://doi.org/10.1016/S1003-6326(19)64986-1

H. Zhang, H. Zhang, and L. Li, Hot Deformation Behavior of Cu-Fe-P Alloys during Compression at Elevated Temperatures, J. Mater. Process. Technol., 2009, 209(6), p 2892–2896.

L. Blaz and A. Nowotnik, High Temperature Deformation of Aluminium Bronze, Mater. Sci. Technol., 2001, 17(8), p 971–975.

Y. Zhang, H.L. Sun, A.A. Volinsky, B.H. Tian, Z. Chai, P. Liu, and Y. Liu, Characterization of the Hot Deformation Behavior of Cu-Cr-Zr Alloy by Processing Maps, Acta Metall. Sin., 2016, 29(5), p 422–430.

H. Chen, P. Gao, H. Peng, H. Wei, W. Xie, H. Wang, and B. Yang, Study on the Hot Deformation Behavior and Microstructure Evolution of Cu-Cr-In Alloy, J. Mater. Eng. Perform., 2019, 28(4), p 2128–2136. https://doi.org/10.1007/s11665-019-03961-z

Q. Lei, Z. Li, J. Wang, S. Li, L. Zhang, and Q. Dong, High-Temperature Deformation Behavior of Cu-6.0Ni-1.0Si-0.5Al-0.15 Mg-0.1Cr Alloy, J. Mater. Sci., 2012, 47(16), p 6034–6042.

L. Zhang, Z. Li, Q. Lei, W.T. Qiu, and H.T. Luo, Hot Deformation Behavior of Cu-8.0Ni-1.8Si-0.15Mg Alloy, Mater. Sci. Eng. A, 2011, 528(3), p 1641–1647.

H. Sun, Y. Zhang, A.A. Volinsky, B. Wang, B. Tian, K. Song, Z. Chai, and Y. Liu, Effects of Ag Addition on Hot Deformation Behavior of Cu–Ni–Si Alloys, Adv. Eng. Mater., 2017, 19(3), p 1–8.

Acknowledgment

The authors would like to thank their colleagues at Material Characterization Division (VSSC) for the support rendered in metallography of the samples. The authors would also like to thank Director, Vikram Sarabhai Space Centre, Trivandrum, for his kind permission to publish this work. The authors would like to acknowledge-the DST-FIST program for funding FESEM-EBSD facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Krishna, S.C., Muneshwar, P., Pant, B. et al. Hot Deformation Behavior and Processing Map of Cu-Cr-Nb-Zr Alloy. J. of Materi Eng and Perform 31, 1325–1337 (2022). https://doi.org/10.1007/s11665-021-06268-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06268-0