Abstract

AZ31 magnesium alloy has poor plastic deformation ability at room temperature due to its hexagonal close-packed (HCP) structure. For traditional plastic forming processes, such as extrusion processes, they can improve the mechanical properties of AZ31 magnesium alloy within a certain range at room temperature. But the coordinated deformation of twin mechanism cannot be neglected during the plastic deformation process. The mechanical properties of AZ31 magnesium alloy exhibit tension–compression yield asymmetry (TCYA). These characteristics of AZ31 magnesium alloy have caused restrictions. As a short forming/preparing integrated process, CVCDE can increase the yield strength (YS) of AZ31 magnesium alloy while effectively improving the TCYA of AZ31 magnesium alloy. In this study, the uniaxial compression test is employed and the quantitative evaluation of the AZ31 magnesium alloy TCYA is carried out by means of the SDE coefficient. With the aid of scanning electron microscopes (SEM) and electron backscattered diffraction (EBSD), the test results indicate that the fracture morphology has changed significantly with the increase in CVCDE interim. The distribution of tear ridges in the fracture area tends to be uniform and the number of dimples increases significantly. The dimples also present a trend of deepening. From the twin distribution, the proportion of {10-12} tensile twins (TTWs) decreased after the AZ31 magnesium alloy processed by CVCDE. This is conducive to the YS in the compression process and the improvement of the TCYA can be obtained.

Similar content being viewed by others

References

C. Suh, S. Shim, S. Shin, and N. Kim, Current Issues in Magnesium Sheet Alloys: Where Do We Go from Here?, Scr. Mater., 2014, 16, p 84–85

Z. Zeng, N. Stanford, J. Davies, F. Nie, and N. Birbilis, Magnesium Extrusion Alloys: A Review of Developments and Prospects, Int. Mater. Rev., 2019, 64, p 1–36

L. Xin, J. Liu, R. Xu, B. Li, and Q. Liu, Changes in Texture and Microstructure of Friction Stir Welded Mg Alloy during Post-rolling and Their Effects on Mechanical Properties, Mater. Sci. Eng. A Struct., 2013, 582, p 178–187

L. Xin, F. Guo, R. Xu, D. Liu, X. Huang, and Q. Liu, Characteristics of Long 10-12 Twin Bands in Sheet Rolling of a Magnesium Alloy, Scr. Mater., 2014, 74, p 96–99

H. Yoo, Slip, Twinning, and Fracture in Hexagonal Close-Packed Metals, Metall. Mater. Trans. A, 1981, 12A, p 409–418

K. Prasad and P. Rao, Processing Maps for Hot Deformation of Rolled AZ31 Magnesium Alloy Plate: Anisotropy of Hot Workability, Mater. Sci. Eng. A Struct., 2008, 487, p 316–327

J. Bohlen, B. Yi, D. Letzig, and U. Kainer, Effect of Rare Earth Elements on the Micro-structure and Texture Development in Magnesium-Manganese Alloys during Extrusion, Mater. Sci. Eng. A Struct., 2010, 527(26), p 7092–7098

M. Lentz, M. Risse, N. Schaefer, W. Reimers, and J. Beyerlein, Strength and Ductility with {1011}-{1012} Double Twinning in a Magnesium Alloy, Nat. Commun., 2016, 7, p 1–7

F. Chai, D. Zhang, W. Zhang, and Y. Li, Microstructure Evolution during High Strain Rate Tensile Deformation of a Fine-Grained AZ91 Magnesium Alloy, Mater. Sci. Eng. A Struct., 2014, 590, p 80–87

J. Ai, G. Fang, J. Zhou, A. Leeflang, and J. Duszczyk, Effect of Twinning on the Deformation Behavior of an Extruded Mg-Zn-Zr Alloy during Hot Compression Testing, Mater. Sci. Eng. A Struct., 2012, 556, p 373–381

Z. Wu, G. Yan, H. Chen, Q. Zhu, B. Su, and L. Zeng, Hot Deformation Behavior and Microstructure Evolution of ZK21 Magnesium Alloy, Mater. Sci. Eng. A Struct., 2010, 527(16–17), p 3670–3675

X. Liu, W. Zhu, C. Xie, J. Zhang, P. Tang, and Q. Chen, Twinning, Dynamic Recrystallization, and Crack in AZ31 Magnesium Alloy during High Strain Rate Plane Strain Compression Across a Wide Temperature, Mater. Sci. Eng. A Struct., 2018, 733, p 98–107

C. Dharmendra, P. Rao, K. Jain, and K. Prasad, Role of Loading Direction on Compressive Deformation Behavior of Extruded ZK60 Alloy Plate in a Wide Range of Temperature, J. Alloys Compd., 2018, 744, p 289–300

W. Wong, A. Hadadzadeh, and A. Wells, High Temperature Deformation Behavior of Extruded AZ31B Magnesium Alloy, J. Mater. Process. Technol., 2018, 251, p 360–368

X. Liu, J. Jonas, X. Li, and W. Zhu, Flow Softening, Twinning and Dynamic Recrystallization in AZ31 Magnesium, Mater. Sci. Eng. A Struct., 2013, 583, p 242–253

X. Wang, G. Fang, A. Leeflang, J. Duszczyk, and J. Zhou, Constitutive Behavior and Microstructure Evolution of the As-Extruded AE21 Magnesium Alloy during Hot Compression Testing, J. Alloys Compd., 2015, 622, p 121–129

K.N. Zhao, D.X. Xu, X. Song, Y.Z. Ma, H.X. Li, J.S. Zhang, and D.L. Chen, Reducing Yield Asymmetry Between Tension and Compression by Fabricating ZK60/WE43 Bimetal Composites, Materials, 2020, 13(1), p 249

B. Lin, D. Wang, M. Peng, and T. Peng, Effect of the Cyclic Extrusion and Compression Processing on Microstructure and Mechanical Properties of As-Extruded ZK60 Magnesium Alloy, Mater. Trans., 2008, 49(5), p 1021–1024

B. Tong, Y. Zheng, S. Kamado, P. Zhang, J. Meng, R. Cheng, and J. Zhang, Reducing the Tension–Compression Yield Asymmetry of Extruded Mg-Zn-Ca Alloy via Equal Channel Angular Pressing, J. Magn. Alloys, 2015, 3, p 302–308

A. Spitzig and O. Richmond, Effect of Pressure on the Flow Stress of Metals, Acta Metall. Sin., 1984, 32, p 457–463

X. Li, F. Li, and W. Li, Microstructural Analysis and Texture Evolution of the CVCEDed AZ31 Magnesium Alloy by Hot Rolling, J. Mater. Eng. Perform., 2018, 27, p 4732–4739

B. Lin, D. Wang, M. Peng, and J. Roven, Microstructure and High Tensile Ductility of ZK60 Magnesium Alloy Processed by Cyclic Extrusion and Compression, J. Alloys Compd., 2009, 476, p 441–445

T. Mukai, M. Yamanoi, H. Watanabe, and K. Higashi, Ductility Enhancement in AZ31 Magnesium Alloy by Controlling Its Grain Structure, Scr. Mater., 2001, 45, p 89–94

M. Avedesian and H. Baker, Magnesium and Magnesium Alloys, ASM Specialty Handbook, Materials Park, ASM International, 1999, p 17

Z. Valiev, K. Islamgaliev, and V. Alexan, Bulk Nanostructure Materials from Severe Plastic Deformation, Prog. Mater. Sci., 2000, 45, p 103–189

K. Hantzsche, J. Bohlen, J. Wendt, U. Kainer, B. Yi, and D. Letzig, Effect of Rare Earth Additions on Microstructure and Texture Development of Magnesium Alloy Sheets, Scr. Mater., 2010, 63, p 725–730

D. Guan, M. Rainforth, J. Gao, J. Sharp, B. Wynne, and L. Ma, Individual Effect of Recrystallisation Nucleation Sites on Texture Weakening in a Magnesium Alloy: Part 1—Double Twins, Acta Mater., 2017, 135, p 14–24

D. Sarker, J. Friedman, and L. Chen, Influence of Pre-strain on De-twinning Activity in an Extruded AM30 Magnesium Alloy, Mater. Sci. Eng. A Struct., 2014, 605, p 73–79

R. Barnett, Twinning and the Ductility of Magnesium Alloys: Part I: “Tension” Twins, Mater. Sci. Eng. A Struct., 2007, 464(1–2), p 1–7

R. Barnett, Twinning and the Ductility of Magnesium Alloys: Part II: “Contraction” Twins, Mater. Sci. Eng. A Struct., 2007, 464(1–2), p 8–16

A. Sisneros, W. Brown, B. Clausen, C. Donati, S. Kabra, R. Blumenthal, and C. Vogel, Influence of Strain Rate on Mechanical Properties and Deformation Texture of Hot-Pressed and Rolled Beryllium, Mater. Sci. Eng. A Struct., 2010, 527(20), p 5181–5188

T. Prado, A. Valle, and A. Ruano, Effect of Sheet Thickness on the Microstructure Evolution of an Mg Alloy during Large Strain Hot Rolling, Scr. Mater., 2004, 50, p 667–671

Z. Li, J. Wang, Z. Li, M. Liu, and T. Liu, Flow Behavior and Processing Map of As-Cast Mg-10Gd-4.8Y-2Zn-0.6Zr Alloy, Mater. Sci. Eng. A Struct., 2010, 528(1), p 154–160

Y. Yang, S. Ji, H. Miura, and T. Sakai, Dynamic Recrystallization and Texture Development during Hot Deformation of Magnesium Alloy AZ31, Trans. Nonferr. Met. Soc., 2009, 19(1), p 55–60

B. Yi, J. Davies, G. Brokmeier, E. Bolmaro, U. Kainer, and J. Homyer, Deformation and Texture Evolution in AZ31 Magnesium Alloy during Uniaxial Loading, Acta Mater., 2006, 54, p 549–562

M. Yin, D. Wu, and X. Li, Tensile-Compressive Yield Asymmetry and Microstructure Evolution during Deformation of Coarse-Grained AZ31D Magnesium Alloy, Chin. J. Mater. Res., 2007, 21, p 38–42

R. Barnett, Z. Keshavarz, and G. Beer, Influence of Grain Size on the Compressive Deformation of Wrought Mg-3Al-1Zn, Acta Mater., 2004, 52(17), p 5093–5103

X. Lou, M. Li, and R. Boger, Hardening Evolution of AZ31B Mg Sheet, Int. J. Plast., 2007, 23(1), p 44–86

Q. Ma, E. Kadiri, and L. Oppedal, Twinning Effects in a Rod-Textured AM30 Magnesium Alloy, Int. J. Plast., 2012, 29, p 60–76

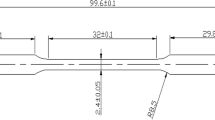

F. Li, X. Zeng, Q. Chen, and J. Cao, Effect of Local Strains on the Texture and Mechanical Properties of AZ31 Magnesium Alloy Produced by Continuous Variable Cross-section Direct Extrusion (CVCDE), Mater. Des., 2015, 85, p 389–395

B. Li and Y. Zhang, Twinning with Zero Twinning Shear, Scr. Mater., 2016, 125, p 73–79

Y. Zhang, B. Li, L. Wu, T. Zhu, Q. Ma, and Q. Liu, Twin Boundaries Showing Very Large Deviations from the Twinning Plane, Scr. Mater., 2012, 67, p 862–865

C. Cayron and R. Loge, Evidence of New Twinning Modes in Magnesium Questioning the Shear Paradigm, J. Appl. Crystallogr., 2018, 51, p 809–817

G. Song and T. Gray, Structural Interpretation of the Nucleation and Growth of Deformation Twins in Zr and Ti—II. Tem Study of Twin Morphology and Defect Reactions during Twinning, Acta Metall. Sin., 1995, 43, p 2339–2350

G. Song and T. Gray, Structural Interpretation of the Nucleation and Growth of Deformation Twins in Zr and Ti—I. Application of the Coincidence Site Lattice (CSL) Theory to Twinning Problems in H.C.P. Structures, Acta Metall. Sin., 1995, 43, p 2325–2337

Y. Wang, F. Li, W. Li, and B. Fang, Unusual Texture Formation and Mechanical Property in AZ31 Magnesium Alloy Sheets Processed by CVCDE, J. Mater. Process. Technol., 2020, 275, p 116360

H. Somekawa, Y. Osawa, and T. Mukai, Effect of Solid-Solution Strengthening on Fracture Toughness in Extruded Mg-Zn Alloys, Scr. Mater., 2006, 55, p 593–596

C. Wonsiewwicz and A. Backofen, Plasticity of Magnesium Crystals, Trans. AIME, 1967, 239, p 1422–1431

F. Li, X. Zeng, and N. Bian, Microstructure of AZ31 Magnesium Alloy Produced by Continuous Variable Cross-section Direct Extrusion (CVCDE), Mater. Lett., 2014, 135, p 79–82

W. Hutchinson and R. Barnett, Effective Values of Critical Resolved Shear Stress for Slip in Polycrystalline Magnesium and Other HCP Metals, Scr. Mater., 2010, 63(7), p 737–740

A. Chapuis and H. Driver, Temperature Dependency of Slip and Twinning in Plane Strain Compressed Magnesium Single Crystals, Acta Mater., 2011, 59(5), p 1986–1994

Y. Liu, F. Li, W. Li, and W. Shi, Properties of Rolled AZ31 Magnesium Alloy Sheet Fabricated by Continuous Variable Cross-section Direct Extrusion, J. Mater. Eng. Perform., 2018, 27, p 1334–1342

C. Xin, J. Zhou, C. Lv, and Q. Liu, The Influence of a Secondary Twin on the Detwinning Deformation of a Primary Twin in Mg-3Al-1Zn Alloy, Mater. Sci. Eng. A Struct., 2014, 606(6), p 81–91

C. Lou, Q. Sun, S. Yang, Y. Ren, Y. Gao, and Y. Zhang, Microstructure and Deformation Mechanism of AZ31 Magnesium Alloy under Dynamic Strain Rate, J. Mater. Eng. Perform., 2018, 27, p 6189–6195

A. Meyers, O. Vohringer, and A. Lubarda, The Onset of Twinning in Metals: A Constitutive Description, Acta Mater., 2001, 49, p 4025–4039

R. Barnett, Z. Keshavarz, G. Beer, and D. Atwell, Influence of Grain Size on the Compressive Deformation of Wrought Mg-3Al-1Zn, Acta Mater., 2004, 52, p 5093–5103

R. Barnett, A Rationale for the Strong Dependence of Mechanical Twinning on Grain Size, Scr. Mater., 2008, 59, p 696–698

Q. Cheng, H. Chen, and J. Xia, Effect of Crystal Orientation on the Ductility in AZ31 Mg Alloy Sheets Produced by Equal Channel Angular Rolling, J. Mater. Sci., 2007, 42, p 3552–3556

D. Wang, J. Chen, B. Lin, J. Zhang, and Q. Zhai, Microstructure and Properties of Magnesium Alloy Processed by a New Severe Plastic Deformation method, Mater. Lett., 2007, 61, p 4599–4602

S. Roodposhti, A. Sarkar, and L. Murty, Creep Deformation Mechanisms and Related Microstructure Development of AZ31 Magnesium Alloy, Magn. Technol., 2015, 12, p 29–34

J. Wang, P. Hirth, and N. Tomé, 10-12 Twinning Nucleation Mechanisms in Hexagonal Close-Packed Crystals, Acta Mater., 2009, 57, p 5521–5530

Y. Liu, N. Li, S. Shao, M. Gong, J. Wang, J. McCabe, Y. Jiang, and N. Tomé, Characterizing the Boundary Lateral to the Shear Direction of Deformation Twins in Magnesium, Nat. Commun., 2016, 7, p 11577

J. Beyerlein, J. McCabeb, and N. Tomé, Effect of Microstructure on the Nucleation of Deformation Twins in Polycrystalline High-Purity Magnesium: A Multi-scale Modeling Study, J. Mech. Phys. Solids, 2011, 59, p 988–1003

J. Beyerlein, J. Demkowicz, A. Misra, and P. Uberuaga, Defect–Interface Interactions, Prog. Mater. Sci., 2015, 74, p 125–210

D. Culbertsona, Q. Yu, J. Wang, and Y. Jiang, Pre-compression Effect on Micro-structure Evolution of Extruded Pure Polycrystalline Magnesium during Reversed Tension Load, Mater. Charact., 2017, 134, p 41–48

J. Wang, K. Yadav, P. Hirth, N. Tomé, and J. Beyerlein, Pure-Shuffle Nucleation of Deformation Twins in Hexagonal-Close-Packed Metals, Mater. Res. Lett., 2013, 1(3), p 126–132

P. Chen, X. Wang, J. Ombogo, and B. Li, Formation of 60°{01-10} Boundaries Between {10-12} Twin Variants in Deformation of a Magnesium Alloy, Mater. Sci. Eng. A Struct., 2019, 739, p 173–185

P. Chen, B. Li, D. Culbertson, and Y. Jiang, Contribution of Extension Twinning to Plastic Strain at Low Stress Stage Deformation of a Mg-3Al-1Zn Alloy, Mater. Sci. Eng. A Struct., 2018, 709, p 40–45

J. Mu, J. Jonas, and G. Gottstein, Variant Selection of Primary, Secondary and Tertiary Twins in a Deformed Mg Alloy, Acta Mater., 2012, 60(5), p 2043–2053

Y. Jin, Y. Liu, Z. Wu, F. Zhong, G. Hou, and H. Zhang, Combination Effects of Yb Addition and Cryogenic Rolling on Microstructure and Mechanical Properties of LA141 Alloy, Mater. Sci. Eng. A Struct., 2020, 788, p 139611

L. Guo, R. Fu, Y. Pei, Q. Wang, Y. Zhao, Y. Song, and C. Chen, Microstructure, Texture, and Mechanical Properties of Continuously Extruded and Rolled AZ31 Magnesium Alloy Sheets, J. Mater. Eng. Perform., 2019, 28, p 6692–6703

Acknowledgments

This project is supported by National Natural Science Foundation of China (No. 51975166).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bian, N., Li, F., Wang, Y. et al. Strengthening Mechanism of Room Temperature Mechanical Properties for AZ31 Magnesium Alloy by Continuous Variable Cross section Direct Extrusion. J. of Materi Eng and Perform 30, 9215–9226 (2021). https://doi.org/10.1007/s11665-021-06111-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06111-6