Abstract

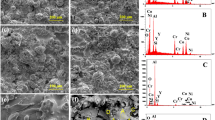

This study is intended to improve the high-temperature oxidation of nano-ZGYbY: ZrO2 9.5Y2O3 5.6Yb2O3 5.2Gd2O3 in order to apply it in the new generation of defect cluster thermal barrier coatings (TBCs) through the employment of an intermediate conventional yttria-stabilized zirconia (micro-YSZ) layer between the bond coat (CoNiCrAlY) and top coat. The specimens were deposited with an atmospheric plasma spray (APS) process on IN738LC superalloy. The cyclic oxidation test was performed in air at 1373 K with 4 h in each cycle. The microstructure of the nano-ZGYbY was studied by field emission scanning electron microscopy, revealing the formation of a bimodal microstructure consisted of nanosized particles retained from the initial APS-processed nanopowder and columnar grains, whereas the microstructure of intermediate micro-YSZ layer consisted of columnar grain splats only. X-ray diffraction of TBCs confirmed the formation of non-transformable (t′) ZrO2 phase (\( \frac{c}{a\sqrt 2 } \) < 1.01) as well as the stability of this phase after oxidation. Also, applying an intermediate conventional YSZ layer with a higher CTE and KIC than that of nano-ZGYbY between the bond and top coats improved mechanical properties in new TBCs and it increased the oxidation life.

Similar content being viewed by others

References

R. Vaßen, M.O. Jarligo, T. Steinke, D.E. Mack, and D. Stöver, Overview on Advanced Thermal Barrier Coatings, Surf. Coat. Technol., 2010, 205, p 938–942

R.S. Lima and B.R. Marple, Thermal Spray Coatings Engineered from Nanostructured Ceramic Agglomerated Powders for Structural, Thermal Barrier And Biomedical Applications: A Review, J. Therm. Spray Technol., 2007, 16, p 40–63

X. Cao, R. Vassen, and D. Stoever, Ceramic Materials for Thermal Barrier Coatings, J. Eur. Ceram. Soc., 2004, 24, p 1–10

Y. Pan, Y. Lin, G. Liu, and J. Zhang, Influence of Transition Metal on the Mechanical and Thermodynamic Properties of IrAl Thermal Barrier Coating, Vacuum, 2020, 174, p 109203

N. Eliaz, G. Shemesh, and R. Latanision, Hot corrosion in Gas Turbine Components, Eng. Fail. Anal., 2002, 9, p 31–43

M. Stiger, N. Yanar, M. Topping, F. Pettit, and G. Meier, Thermal Barrier Coatings for the 21st Century, Z. Metall., 1999, 90, p 1069–1078

M. Bahamirian and Sh Khameneh Asl, An Investigation on Effect of Bond Coat Replacement on Hot Corrosion Properties of Thermal Barrier Coatings, Iran. J. Mater. Sci. Eng., 2013, 10, p 12–21

R. Lima and B. Marple, Nanostructured YSZ Thermal Barrier Coatings Engineered to Counteract Sintering Effects, Mater. Sci. Eng., A, 2008, 485, p 182–193

A. Keyvani, M. Bahamirian, and A. Kobayashi, Effect of Sintering Rate on the Porous Microstructural, Mechanical and Thermomechanical Properties of YSZ and CSZ TBC Coatings Undergoing Thermal Cycling, J. Alloys Compd., 2017, 727, p 1057–1066

M. Loghman-Estarki, R.S. Razavi, and H. Jamali, Thermal Stability and Sintering Behavior of Plasma Sprayed Nanostructured 7YSZ, 15YSZ and 5.5 SYSZ Coatings at Elevated Temperatures, Ceram. Int., 2016, 42, p 14374–14383

S. Paul, A. Cipitria, S. Tsipas, and T. Clyne, Sintering Characteristics of Plasma Sprayed Zirconia Coatings Containing Different Stabilisers, Surf. Coat. Technol., 2009, 203, p 1069–1074

A. Keyvani and M. Bahamirian, Hot Corrosion and Mechanical Properties of Nanostructured Al2O3/CSZ Composite TBCs, Surf. Eng., 2017, 33, p 433–443

M. Bahamirian, S. Hadavi, M. Farvizi, M. Rahimipour, and A. Keyvani, Enhancement of Hot Corrosion Resistance of Thermal Barrier Coatings by Using Nanostructured Gd2Zr2O7 Coating, Surf. Coat. Technol., 2019, 360, p 1–12

M.R. Loghman-Estark, R.S. Razavi, and H. Edris, Synthesis and Thermal Stability of Nontransformable Tetragonal (ZrO2)0.96(REO1.5)0.04(Re = Sc3+, Y3+) Nanocrystals, Defect Diffus. Forum, 2013, 334, p 60–64

C. Viazzi, J.-P. Bonino, F. Ansart, and A. Barnabé, Structural Study of Metastable Tetragonal YSZ Powders Produced Via a Sol–Gel Route, J. Alloys Compd., 2008, 452, p 377–383

M. Shahid and M. Abbas, Investigation of Failure Mechanism of Thermal Barrier Coatings (TBCs) Deposited by EB-PVD Technique, J. Phys: Conf. Ser., 2013, 439, p 012021

Y. Tang, Failure Analysis of Thermal Barrier Coatings. Ph.D. Thesis, Tulane University, Tulane, USA (2007)

K. Carlsson, A Study of Failure Development in Thick Thermal Barrier Coatings. Independent Thesis Advanced Level (degree of Magister), Linköping University (2007)

K.W. Schlichting, N. Padture, E. Jordan, and M. Gell, Failure Modes in Plasma-Sprayed Thermal Barrier Coatings, Mater. Sci. Eng., A, 2003, 342, p 120–130

N.P. Padture, Advanced Structural Ceramics in Aerospace Propulsion, Nat. Mater., 2016, 15, p 804–809

T. Narita, T. Izumi, T. Nishimoto, Y. Shibata, K.Z. Thosin, and S. Hayashi, Advanced Coatings on High Temperature Applications, Mater. Sci. Forum, 2006, 522, p 1–14

U. Schulz, C. Leyens, K. Fritscher, M. Peters, B. Saruhan-Brings, O. Lavigne et al., Some Recent Trends in Research and Technology of Advanced Thermal Barrier Coatings, Aerosp. Sci. Technol., 2003, 7, p 73–80

Y. Pan, D. Pu, and Y. Jia, Adjusting the Correlation Between the Oxidation Resistance and Mechanical Properties of Pt-Based Thermal Barrier Coating, Vacuum, 2020, 172, p 109067

A. Keyvani, N. Mostafavi, M. Bahamirian, H. Sina, and A. Rabiezadeh, Synthesis and Phase Stability of Zirconia-Lanthania-Ytterbia-Yttria Nanoparticles; a Promising Advanced TBC Material, Asian Ceram. Soc., 2020, 8, p 336–344

M.B.A. Keyvani and B. Esmaeili, Sol-Gel Synthesis and Characterization of ZrO2-25wt.%CeO2-2.5wt.%Y2O3 (CYSZ) Nanoparticles, Ceram. Int., 2020, 20, p 30

A. Keyvani, P. Mahmoudinezhad, A. Jahangiri, and M. Bahamirian, Synthesis and Characterization of ((La1-xGdx)2Zr2O7; x = 0, 0.1, 0.2, 0.3, 0.4, 0.5, 1) Nanoparticles for Advanced TBCs, J. Aust. Ceram. Soc., 2020, 20, p 30

S. Metco, Material Product Data Sheet: Zirconia Gadolinia Ytterbia Yttria Agglomerated and Sintered Thermal Spray Powder. DSMTS-0099.4 (2015)

D. Zhu and R.A. Miller, Development of Advanced Low Conductivity Thermal Barrier Coatings, Int. J. Appl. Ceram. Technol., 2004, 1, p 86–94

S.M.M.H.M. Bahamirian, M. Farvizi, A. Keyvani, and M.R. Rahimipour, ZrO2 9.5 Y2O3 5.6 Yb2O3 5.2 Gd2O3; a Promising TBC Material with High Resistance to Hot Corrosion, J. Asian Ceram. Soc., 2020, 20, p 30

M. Bahamirian, S. Hadavi, M. Farvizi, M. Rahimipour, and A. Keyvani, Phase Stability of ZrO2 9.5 Y2O3 5.6 Yb2O3 5.2 Gd2O3 Compound at 1100 C and 1300 C for Advanced TBC Applications, Ceram. Int., 2019, 45, p 7344–7350

S.-H. Jung, Z. Lu, Y.-G. Jung, D. Song, U. Paik, B.-G. Choi et al., Thermal Durability and Fracture Behavior of Layered Yb-Gd-Y-Based Thermal Barrier Coatings in Thermal Cyclic Exposure, Surf. Coat. Technol., 2017, 323, p 39–48

Z.-G. Liu, W.-H. Zhang, J.-H. Ouyang, and Y. Zhou, Novel Double-Ceramic-Layer (La0.8Eu0.2)2Zr2O7/YSZ Thermal Barrier Coatings Deposited by Plasma Spraying, Ceram. Int., 2014, 40, p 11277–11282

X. Xiaoyun, G. Hongbo, G. Shengkai, and X. Huibin, Hot Corrosion Behavior of Double-Ceramic-Layer LaTi2Al9O19/YSZ Thermal Barrier Coatings, Chin. J. Aeronaut., 2012, 25, p 137–142

L. Wang, Y. Wang, X. Sun, J. He, Z. Pan, and C. Wang, Finite Element Simulation of Residual Stress of Double-Ceramic-Layer La2Zr2O7/8YSZ Thermal Barrier Coatings Using Birth and Death Element Technique, Comput. Mater. Sci., 2012, 53, p 117–127

R. Vassen, F. Traeger, and D. Stöver, New Thermal Barrier Coatings Based on Pyrochlore/YSZ Double-Layer Systems, Int. J. Appl. Ceram. Technol., 2004, 1, p 351–361

M. Gell, Application Opportunities for Nanostructured Materials and Coatings, Mater. Sci. Eng., A, 1995, 204, p 246–251

C.-B. Liu, Z.-M. Zhang, X.-L. Jiang, L. Min, and Z.-H. Zhu, Comparison of Thermal Shock Behaviors Between Plasma-Sprayed Nanostructured and Conventional Zirconia Thermal Barrier Coatings, Trans. Nonferrous Met. Soc. China, 2009, 19, p 99–107

C. Zhou, N. Wang, and H. Xu, Comparison of Thermal Cycling Behavior of Plasma-Sprayed Nanostructured and Traditional Thermal Barrier Coatings, Mater. Sci. Eng., A, 2007, 452, p 569–574

H. Chen, X. Zhou, and C. Ding, Investigation of the Thermomechanical Properties of a Plasma-Sprayed Nanostructured Zirconia Coating, J. Eur. Ceram. Soc., 2003, 23, p 1449–1455

R. Lima, A. Kucuk, and C. Berndt, Evaluation of Microhardness and Elastic Modulus of Thermally Sprayed Nanostructured Zirconia Coatings, Surf. Coat. Technol., 2001, 135, p 166–172

M. Bahamirian, S. Hadavi, M. Rahimipour, M. Farvizi, and A. Keyvani, Synthesis and Characterization of Yttria-Stabilized Zirconia Nanoparticles Doped with Ytterbium and Gadolinium: ZrO2 9.5 Y2O3 5.6 Yb2O3 5.2 Gd2O3, Metall. Mater. Trans. A, 2018, 49, p 2523–2532

M.R. Loghman-Estarki, H. Edris, H. Jamali, R. Ghasemi, M. Pourbafrany, M. Erfanmanesh et al., Spray Drying of Nanometric SYSZ Powders to Obtain Plasma Sprayable Nanostructured Granules, Ceram. Int., 2013, 39, p 9447–9457

R. Aminov, A. Moskalenko, and A. Kozhevnikov, Optimal Gas Turbine Inlet Temperature for Cyclic Operation, J. Phys: Conf. Ser., 2018, 1111, p 012046

ASTM standard-E228, Standard Test Method for Linear Thermal Expansion of Solid Materials with a Push-Rod Dilatometer (1995)

T. Samani, M. Kermani, M. Razavi, M. Farvizi, and I. Mobasherpour, A Comparative Study on the Microstructure, Hot Corrosion Behavior and Mechanical Properties of Duplex and Functionally Graded Nanostructured/Conventional YSZ Thermal Barrier Coatings, Mater. Res. Exp., 2019, 6, p 115063

S. Bose, Chapter 7—Thermal Barrier Coatings (TBCs), High Temperature Coatings, Elsevier, Amsterdam, 2007, p 155–232

F.-W. Bach, K. Möhwald, A. Laarmann, and T. Wenz, Modern Surface Technology, Wiley, New York, 2006

A. Kucuk, C. Berndt, U. Senturk, R. Lima, and C. Lima, Influence of Plasma Spray Parameters on Mechanical Properties of Yttria Stabilized Zirconia Coatings. I: Four Point Bend Test, Mater. Sci. Eng., A, 2000, 284, p 29–40

J. Ilavsky and J.K. Stalick, Phase Composition and Its Changes During Annealing of Plasma-Sprayed YSZ, Surf. Coat. Technol., 2000, 127, p 120–129

H. Grünling and W. Mannsmann, Plasma Sprayed Thermal Barrier Coatings for Industrial Gas Turbines: Morphology, Processing and Properties, Le J. Phys. IV, 1993, 3, p C7-903–C7-912

L. Wang, Y. Wang, X. Sun, J. He, Z. Pan, Y. Zhou et al., Influence of Pores on the Thermal Insulation Behavior of Thermal Barrier Coatings Prepared by Atmospheric Plasma Spray, Mater. Des., 2011, 32, p 36–47

I. Golosnoy, A. Cipitria, and T. Clyne, Heat Transfer Through Plasma-Sprayed Thermal Barrier Coatings in Gas Turbines: A Review of Recent Work, J. Therm. Spray Technol., 2009, 18, p 809–821

A. Cipitria, I. Golosnoy, and T. Clyne, A Sintering Model for Plasma-Sprayed Zirconia TBCs. Part I: Free-Standing Coatings, Acta Mater., 2009, 57, p 980–992

O. Racek and C. Berndt, Mechanical Property Variations Within Thermal Barrier Coatings, Surf. Coat. Technol., 2007, 202, p 362–369

R. Lima, A. Kucuk, and C. Berndt, Integrity of Nanostructured Partially Stabilized Zirconia After Plasma Spray Processing, Mater. Sci. Eng., A, 2001, 313, p 75–82

R. Ghasemi, R. Shoja-Razavi, R. Mozafarinia, and H. Jamali, Comparison of Microstructure and Mechanical Properties of Plasma-Sprayed Nanostructured and Conventional Yttria Stabilized Zirconia Thermal Barrier Coatings, Ceram. Int., 2013, 39, p 8805–8813

E.H. Kisi and C. Howard, Crystal Structures of Zirconia Phases and Their Inter-relation, Key Eng. Mater., 1998, 153, p 1–36

T. Sakuma, Microstructural Aspects on the Cubic-Tetragonal Transformation in Zirconia, Key Eng. Mater., 1998, 153, p 75–96

A. Keyvani, M. Saremi, M.H. Sohi, and Z. Valefi, A Comparison on Thermomechanical Properties of Plasma-Sprayed Conventional and Nanostructured YSZ TBC Coatings in Thermal Cycling, J. Alloys Compd., 2012, 541, p 488–494

H. Xu and H. Guo, Thermal Barrier Coatings, Woodhead Publishing Limited, Singapore, 2011, p 193–197

A. Keyvani and M. Bahamirian, Oxidation Resistance of Al2O3-Nanostructured/CSZ Composite Compared to Conventional CSZ and YSZ Thermal Barrier Coatings, Mater. Res. Exp., 2016, 3, p 105047

Z. Zou, L. Jia, L. Yang, X. Shan, L. Luo, F. Guo et al., Role of Internal Oxidation on the Failure of Air Plasma Sprayed Thermal Barrier Coatings with a Double-Layered Bond Coat, Surf. Coat. Technol., 2017, 319, p 370–377

M. Bahamirian, S. Hadavi, M. Farvizi, A. Keyvani, and M. Rahimipour, Thermal Durability of YSZ/Nanostructured Gd2Zr2O7 TBC Undergoing Thermal Cycling, Oxid. Met., 2019, 92, p 401–421

H.-J. Jang, D.-H. Park, Y.-G. Jung, J.-C. Jang, S.-C. Choi, and U. Paik, Mechanical Characterization and Thermal Behavior of HVOF-Sprayed Bond Coat in Thermal Barrier Coatings (TBCs), Surf. Coat. Technol., 2006, 200, p 4355–4362

Y.-S. Song, I.-G. Lee, D.Y. Lee, D.-J. Kim, S. Kim, and K. Lee, High-Temperature Properties of Plasma-Sprayed Coatings of YSZ/NiCrAlY on Inconel Substrate, Mater. Sci. Eng., A, 2002, 332, p 129–133

J.S. Wallace and J. Ilavsky, Elastic Modulus Measurements in Plasma Sprayed Deposits, J. Therm. Spray Technol., 1998, 7, p 521–526

F. Tang and J.M. Schoenung, Evolution of Young’s Modulus of Air Plasma Sprayed Yttria-Stabilized Zirconia in Thermally Cycled Thermal Barrier Coatings, Scr. Mater., 2006, 54, p 1587–1592

Z. Wu, L. Ni, Q. Yu, and C. Zhou, Effect of Thermal Exposure on Mechanical Properties of a Plasma-Sprayed Nanostructured Thermal Barrier Coating, J. Therm. Spray Technol., 2012, 21, p 169–175

H. Chen, S.W. Lee, H. Du, C.X. Ding, and C.H. Choi, Influence of Feedstock and Spraying Parameters on the Depositing Efficiency and Microhardness of Plasma-Sprayed Zirconia Coatings, Mater. Lett., 2004, 58, p 1241–1245

M. Bacos, J. Dorvaux, O. Lavigne, R. Mévrel, R. Poulain, C. Rio et al., Performance and Degradation Mechanisms of Thermal Barrier Coatings for Turbine Blades: A Review of Onera Activities, AerospaceLab, 2011, 3, p 1–11

T. Beck, R. Herzog, O. Trunova, M. Offermann, R.W. Steinbrech, and L. Singheiser, Damage Mechanisms and Lifetime Behavior of Plasma-Sprayed Thermal Barrier Coating Systems for Gas Turbines—Part II: Modeling, Surf. Coat. Technol., 2008, 202, p 5901–5908

A.G. Evans, D. Mumm, J. Hutchinson, G. Meier, and F. Pettit, Mechanisms Controlling the Durability of Thermal Barrier Coatings, Prog. Mater Sci., 2001, 46, p 505–553

K. Ogawa, High Temperature Oxidation Behavior of Thermal Barrier Coatings, Gas Turbines-Materials, Modeling and Performance, IntechOpen, London, 2015

E. Busso, J. Lin, S. Sakurai, and M. Nakayama, A Mechanistic Study of Oxidation-Induced Degradation in a Plasma-Sprayed Thermal Barrier Coating System: Part I: Model Formulation, Acta Mater., 2001, 49, p 1515–1528

A. Reddy, D. Hovis, A. Heuer, A. Paulikas, and B. Veal, In Situ Study of Oxidation-Induced Growth Strains in a Model NiCrAlY Bond-Coat Alloy, Oxid. Met., 2007, 67, p 153–177

M. Abbas, H. Guo, and M.R. Shahid, Comparative Study on Effect of Oxide Thickness on Stress Distribution of Traditional and Nanostructured Zirconia Coating Systems, Ceram. Int., 2013, 39, p 475–481

M. Ali, S. Nusier, and G. Newaz, Mechanics of Damage Initiation and Growth in a TBC/Superalloy System, Int. J. Solids Struct., 2001, 38, p 3329–3340

D. Chicot and A. Tricoteaux, Mechanical Properties of Ceramic by Indentation: Principle and Applications, Ceramic Materials, InTech, London, 2010

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

According to Ref. 78, to measure the hardness of the coatings, micro Vickers method was employed. 300 gf load and loading time of 10 s were used for this purpose. Eq 4 was used for hardness calculation.

In this equation, “HV” represents Vickers hardness, “P” denotes the load in “gf,” and “d” stands for the mean diameter effect of indentation in “mm”.

Elastic modulus was measured using Knoop indentation test. For which, Eq 5 was used.

In this equation, \( \frac{b}{a} \) = 0.141 which is related to the geometry of indenter and also, “a′” and “b′” are the effect of indentation diameters. In this equation, “H” was obtained according to Vickers indenter to calculate elastic modulus (E). “α” was considered constant 0.45.

Crack length measurement can be used in Vickers hardness test to determine fracture toughness of ceramics. Fracture toughness of the specimens can be measured by Eq 6.

where “KIC” denotes fracture toughness; “P” and “C” are indenting load and mean length of crack, respectively. “H” and “E” also show Vickers hardness and Young’s modulus, respectively.

Rights and permissions

About this article

Cite this article

Bahamirian, M., Hadavi, S.M.M., Farvizi, M. et al. Microstructure and Cyclic Oxidation of Yttria-Stabilized Zirconia/Nanostructured ZrO2 9.5Y2O3 5.6Yb2O3 5.2Gd2O3 Thermal Barrier Coating at 1373 K. J. of Materi Eng and Perform 29, 7080–7093 (2020). https://doi.org/10.1007/s11665-020-05174-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05174-1