Abstract

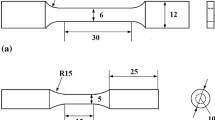

Fatigue properties of an Al-Si-Cu cast alloy were investigated with life up to very high cycle fatigue regime. Particular attention was given to specimen size effect and fatigue crack initiation mechanism. Uniaxial fatigue tests with constant amplitudes were carried out by using ultrasonic fatigue testing machine operating at 20 kHz, compared to the results obtained by using conventional hydraulic fatigue machine at 35 Hz. In order to evaluate the size effect, two sets of specimens with different dimensions were used. The results show that the fatigue strength of the studied alloy decreases with the increase in specimen size. Scanning electron microscopy observation of fracture surfaces revealed that most fatigue cracks initiated from microstructural defects such as porosity located on specimen surface or in subsurface. Weibull statistical analysis of fatigue data accounting for size effect was performed to predict the fatigue life of the Al-Si-Cu alloy in the very high cycle regime. Good agreement was found between the fatigue life prediction and the experimental data.

Similar content being viewed by others

References

C. Bathias, Piezoelectric Fatigue Testing Machines and Devices, Int. J. Fatigue, 2006, 28, p 1438–1445

H. Mayer, Ultrasonic Torsion and Tension–Compression Fatigue Testing: Measuring Principles and Investigations on 2024-T351 Aluminum Alloy, Int. J. Fatigue, 2006, 28, p 1446–1455

C. Bathias and P.C. Pari, Gigacycle Fatigue in Mechanical Practice, Marcel Dekker, New York, 2005

H. Mayer, M. Papakyriacou, B. Zettl, and S.E. Stanzl-Tschegg, Influence of Porosity on the Fatigue Limit of Die Cast Magnesium and Aluminum Alloys, Int. J. Fatigue, 2003, 25, p 245–256

M.J. Caton, J.W. Jones, H. Mayer, S.E. Stanzl-Tschegg, and J.E. Allison, Demonstration of an Endurance Limit in Cast 319 Aluminum, Metall. Mater. Trans. A, 2003, 34, p 33–40

M.J. Caton, J.W. Jones, and J.E. Allison, The Influence of Heat Treatment and Solidification Time on the Behavior of Small Fatigue Cracks in a Cast Aluminum Alloy, Mater. Sci. Eng. A, 1998, 314, p 81–85

H.R. Ammar, A.M. Samuel, and F.H. Samuel, Porosity and the Fatigue Behavior of Hypoeutectic and Hypereutectic Aluminum-Silicon Casting Alloys, Int. J. Fatigue, 2008, 30, p 1024–1035

P. Mu, Y. Nadot, C. Nadot-Martin, A. Chabod, I. Serrano-Munoz, and C. Verdu, Influence of Casting Defects on the Fatigue Behavior of Cast Aluminum AS7G06-T6, Int. J. Fatigue, 2014, 63, p 97–109

I. Koutiri, D. Bellett, F. Morel, and E. Pessard, A Probabilistic Model for the High Cycle Fatigue Behaviour of Cast Aluminium Alloys Subject to Complex Loads, Int. J. Fatigue, 2013, 47, p 137–147

R. Gonzalez, D.I. Martinez, J.A. Gonzalez, J. Talamantes, S. Valtierra, and R. Colas, Experimental Investigation for Fatigue Strength of a Cast Aluminium Alloy, Int. J. Fatigue, 2011, 33, p 273–278

D.A. Lados and D. Apelian, Relationships Between Microstructure and Fatigue Crack Propagation Paths in Al-Si-Mg Cast Alloys, Eng. Fract. Mech., 2008, 75, p 821–832

L. Zeng, J. Sakamoto, A. Fujii, and H. Noguchi, Role of Eutectic Silicon Particles in Fatigue Crack Initiation and Propagation and Fatigue Strength Characteristics of Cast Aluminum Alloy A356, Eng. Fract. Mech., 2014, 115, p 1–12

P. Li, P.D. Lee, D.M. Maijer, and T.C. Lindley, Quantification of the Interaction Within Defect Populations on Fatigue Behavior in an Aluminum Alloy, Acta Mater., 2009, 57, p 3539–3548

V.D. Le, F. Morel, D. Bellett, N. Saintier, and P. Osmond, Simulation of the Kitagawa-Takahashi Diagram Using a Probabilistic Approach for Cast Al-Si Alloys Under Different Multiaxial Loads, Int. J. Fatigue, 2016, 93, p 109–121

I. Serrano-Munoz, J.Y. Buffiere, C. Verdu, Y. Gaillard, P. Mu, and Y. Nadot, Influence of Surface and Internal Casting Defects on the Fatigue Behavior of A357-T6 Cast Aluminium Alloy, Int. J. Fatigue, 2016, 82, p 361–370

C. Bruggera, T. Palin-Luc, P. Osmondb, and M. Blanc, Gigacycle Fatigue Behavior of a Cast Aluminum Alloy Under Biaxial Bending: Experiments with a New Piezoelectric Fatigue Testing Device, Proc. Struct. Integr., 2016, 2, p 1173–1180

X. Zhu, A. Shyam, J.W. Jones, H. Mayer, J.V. Lasecki, and J.F. Allison, Effects of Microstructure and Temperature on Fatigue Behavior of E319-T7 Cast Aluminum Alloy in Very Long Life Cycles, Int. J. Fatigue, 2006, 28, p 1566–1571

A. Ezanno, C. Doudard, S. Calloch, and J.P. Heuzé, A New Approach to Characterizing and Modeling the High Cycle Fatigue Properties of Cast Materials Based on Self-Heating Measurements Under Cyclic Loadings, Int. J. Fatigue, 2013, 47, p 232–243

S. Mohd, Y. Mutoh, Y. Otsuka, Y. Miyashita, T. Koike, and T. Suzuki, Scatter Analysis of Fatigue Life and Pore Size Data of Die-Cast AM60B Magnesium Alloy, Eng. Fail. Anal., 2012, 22, p 64–72

S. Dezecot and M. Brochu, Microstructural Characterization and High Cycle Fatigue Behavior of Investment Cast A357 Aluminum Alloy, Int. J. Fatigue, 2015, 77, p 154–159

Y. Furuya, Specimen Size effects on Gigacycle Fatigue Properties of High-Strength Steel Under Ultrasonic Fatigue Testing, Scr. Mater., 2008, 58, p 1014–1017

Y. Murakami, Stress concentration, Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions, Y. Murakami, Ed., Elsevier, Oxford, 2002, p 11–24

H. Xue, Explanation on Gigacycle Fatigue of Materials in Tension, Bending and Torsion Loading, PhD thesis, CNAM, Paris, 2005

H. Xue, H. Tao, and C. Bathias, The Analysis of Specimen Design for Fatigue Test at Ultrasonic Frequency, VHCF3, 2004, p 456-463

H. Xue, T. Wu, and C. Bathias, Gigacycle Fatigue Behavior of Cast Aluminum in Tension and Torsion Loading, Trans. Nanjing Univ. Aeronaut. Astronaut., 2011, 28, p 32–37

V.D. Le, F. Morel, D. Bellett, N. Saintier, and P. Osmond, Multiaxial High Cycle Fatigue Damage Mechanisms Associated with the Different Microstructural Heterogeneities of Cast Aluminium Alloys, Mater. Sci. Eng. A, 2016, 649, p 426–440

T.O. Mbuya, I. Sinclair, A.J. Moffat, and P.A.S. Reed, Analysis of Fatigue Crack Initiation and S-N Response of Model Cast Aluminium Piston Alloys, Mater. Sci. Eng. A, 2011, 528, p 7331–7340

R. Gonzalez, A. Gonzalez, J. Talamantes-Silva, S. Valtierra, R.D. Mercado-Solis, N.F. Garza-Montes-de-Oca, and R. Colas, Fatigue of an Aluminium Cast Alloy Used in the Manufacture of Automotive Engine Blocks, Int. J. Fatigue, 2013, 54, p 118–126

M. Shirani and G. Harkegard, Fatigue Life Distribution and Size Effect in Ductile Cast Iron for Wind Turbine Components, Eng. Fail. Anal., 2011, 18, p 12–24

A. Cetin, A. Naess, and G. Harkegard, A Physically Based Extreme Value Characterization of Material Fatigue, Int. J. Fatigue, 2013, 47, p 216–221

A. Wormsen, B. Sjodin, G. Harkegard, and A. Fjeldstad, Non-local Stress Approach for Fatigue Assessment Based on Weakest-Link Theory and Statistics of Extremes, Fatig. Fract. Eng. Mater. Struct., 2007, 30, p 1214–1227

H.P. Gaenser, Some Notes on Gradient, Volumetric and Weakest Link Concepts in Fatigue, Comput. Mater. Sci., 2008, 44, p 230–239

H. Belmonte, M. Mulheron, and P. Smith, Weibull Analysis, Extrapolations and Implications for Condition Assessment of Cast Iron Water Mains, Fatig. Fract. Eng. Mater. Struct., 2007, 30, p 964–990

C.M. Sonsino, Course of SN-Curves Especially in the High-Cycle Fatigue Regime with Regard to Component Design and Safety, Int. J. Fatigue, 2007, 29, p 2246–2258

S. Romano, A. Brückner-Foit, A. Brandão, J. Gumpinger, T. Ghidini, and S. Beretta, Fatigue Properties of AlSi10Mg Obtained by Additive Manufacturing: Defect-based Modelling and Prediction of Fatigue Strength, Eng. Fract. Mech., 2018, 187, p 165–189

Acknowledgments

The authors gratefully acknowledge the financial supports provided by Natural Science Basic Research Plan in Shaanxi Province of China (No. 2015JM1007) and the 111 Project, Grant No. B13044.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, H., Sun, Z., Zhang, X. et al. Very High Cycle Fatigue of a Cast Aluminum Alloy: Size Effect and Crack Initiation. J. of Materi Eng and Perform 27, 5406–5416 (2018). https://doi.org/10.1007/s11665-018-3617-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3617-y