Abstract

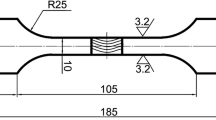

2219-C10S and 2219-CYS aluminum alloys are 2219 aluminum alloys with different heat treatment processes, and they have been widely used in the aerospace industry. In the present study, 2219-C10S and 2219-CYS aluminum alloys were butt-welded by three-layer tungsten inert gas arc welding (with the welding center of the third layer shifted toward the CYS side), and the microstructure characteristics and mechanical properties of the welded joint were investigated. The lamellar θ′ phases, the bulk or rod θ phases, and the coarse rod-shaped or pancake-shaped Al-Cu-Fe-Mn phases coexisted in the two aluminum alloys. The Cu content of the α-Al matrix and the distribution of eutectic structures of different welding layers in the weld zone (WZ) were varied, implying that the segregation degrees of the Cu element were different due to the different welding thermal cycles in different welding layers. The microhardness values of the CYS side were much higher than those of the C10S side in each region on both sides of the joint. The tensile test deformation was concentrated mainly in the regions of WZ and the over aged zone (OAZ), where the microhardness values were relatively low. The main deformation concentrated region was transferred from the CYS side to the C10S side with the increase in the tensile load during the tensile test. The fracture behavior of the tensile test showed that the macroscopic crack initiated near the front weld toe had gone through the crack blunt region, the shear fracture region of the partially melted zone (PMZ), and the shear fracture region of OAZ. Meanwhile, the fracture characteristics gradually evolved from brittle to ductile. The concentrated stress and the dense eutectic structure in the region near the front weld toe of the C10S side contributed to the fracture of the joint. The shift of the welding center of the third layer to the CYS side resulted in two effects: (i) the microhardness values from the middle layer to the top layer in the PMZ of the CYS side were the most significantly increased and (ii) the distance between the front weld toe and the fusion line of the CYS side was significantly larger.

Similar content being viewed by others

References

G. Venkata Narayana, V.M.J. Sharma, V. Diwakar, K.S. Kumar, and R.C. Prasad, Fracture Behaviour of Aluminium Alloy 2219-T87 Welded Plates, Sci. Technol. Weld. Join., 2004, 9, p 121–130

S.V.S.N. Murty, A. Sarkar, P.R. Narayanan, P.V. Venkitakrishnan, and J. Mukhopadhyay, Microstructure and Micro-Texture Evolution During Large Strain Deformation of Aluminium Alloy AA 2219, Mater. Sci. Eng. A, 2016, 677, p 41–49

R.P. Naga, R.K. Srinivasa, G.M. Reddy, M. Kamaraj, and R.K. Prasad, Microstructure and High Temperature Stability of Age Hardenable AA2219 Aluminium Alloy Modified by Sc, Mg and Zr Additions, Mater. Sci. Eng. A, 2007, 464, p 192–201

J. Zhang, B.Q. Chen, and B.X. Zhang, Effect of Initial Microstructure on the Hot Compression Deformation Behavior of A 2219 Aluminum Alloy, Mater. Des., 2012, 34, p 15–21

Y.T. Lin, M.C. Wang, Y. Zhang, Y.Z. He, and D.P. Wang, Investigation of Microstructure Evolution After Post-Weld Heat Treatment and Cryogenic Fracture Toughness of the Weld Metal of AA2219 VPTIG Joints, Mater. Des., 2017, 113, p 54–59

H.M. Wang, Y.P. Yi, and S.Q. Huang, Investigation of Quench Sensitivity of High Strength 2219 Aluminum Alloy by TTP and TTT Diagrams, J. Alloys Compd., 2017, 690, p 446–452

G.M. Karthik, G.D.J. Ram, and R.S. Kottada, Heat-Affected Zone Liquation Cracking Resistance of Friction Stir Processed Aluminum–Copper Alloy AA 2219, Metall. Mater. Trans. B, 2017, 48(B), p 1158–1173

B. Du, L. Cui, X.Q. Yang, D.P. Wang, and Z.P. Sun, Weakening Mechanism and Tensile Fracture Behavior of AA 2219-T87 Friction Plug Welds, Mater. Sci. Eng. A, 2017, 693, p 129–135

J.Y. Bai, C.L. Fan, S.B. Lin, C.L. Yang, and B.L. Dong, Effects of Thermal Cycles on Microstructure Evolution of 2219-Al During GTA-Additive Manufacturing, Int. J. Adv. Manuf. Technol., 2016, 87, p 2615–2623

J.K. Ding, D.P. Wang, Y. Wang, and H. Du, Effect of Post Weld Heat Treatment on Properties of Variable Polarity TIG Welded AA2219 Aluminium Alloy Joints, Trans. Nonferr. Met. Soc. China, 2014, 24(5), p 1307–1316

A.C. Nunes, E.O. Bayless, C.S. Jones, P.M. Munafo, A.P. Biddle, and W.A. Wilson, Variable Polarity Plasma Arc Welding on the Space Shuttle External Tank, Weld. J., 1984, 63, p 27–35

J.A. Hartman, R.J. Beil, and G.T. Hahn, Effect of Copper-Rich Regions on Tensile Properties of VPPA Weldments of 2219-T87 Aluminum, Weld. Res. Suppl., 1987, 32, p 73–83

Z.Y. Zhu, C.Y. Deng, Y. Wang, Z.W. Yang, J.K. Ding, and D.P. Wang, Effect of Post Weld Heat Treatment on the Microstructure and Corrosion Behavior of AA 2219 Aluminum Alloy Joints Welded by Variable Polarity Tungsten Inert Gas Welding, Mater. Des., 2015, 65, p 1075–1082

G.Q. Wang, L.Y. Xiong, Z.J. Tian, K.Y. Dong, and Q. Liu, Microstructure and Property of TIG Welded 2219 Aluminum Alloy by Different Heat Treatment, Trans. China Weld. Inst., 2017, 38(1), p 121–124

H.W. Liu, J.L. Song, Z.P. Sun, Y.Y. Miao, and F. Liu, Study on the Properties of 2219 Aluminum Alloy TIG Welded Joint with Different Heat Treatment Conditions, Weld. Join., 2014, 10, p 58–60

Q. Li, A.P. Wu, Y. Zhao, G.Q. Wang, D.Y. Yan, and H.Q. Wu, Fracture Behavior of Double-Structures TIG Welded 2219-T8 Aluminum Alloy Joints Under Transverse Tensile Test, Trans. Nonferr. Met. Soc. China, 2015, 25, p 1794–1803

M.P. John, A Calorimetric Study of Precipitation in Aluminum Alloy 2219, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 1981, 12(2), p 269–280

H. Xiong, L.J. Zhuang, W.Q. Qu, J.S. Yao, and Y.H. Yin, Microstructures and Mechanical Properties of 2219-T87 Aluminum Alloy TIG Welded Joints, Aeronaut. Manuf. Technol., 2014, 10, p 75–78

X.M. Mao, H.Z. Fu, and Y.H. Zhou, Deviation of Solute Redistribution from Equilibrium at the S/L Inter-Face During Crystallization of Al–Cu Alloys, J. Northwest. Polytech. Univ., 1985, 3(1), p 11–20

J.A. Sarreal and G.J. Abbaschian, The Effect of Solidification Rate on Microsegregation, Metall. Mater. Trans. A, 1986, 17(11), p 2063–2073

Q. Li, A.P. Wu, Y.J. Li, G.Q. Wang, D.Y. Yan, and J. Liu, Influence of Temperature Cycles on the Microstructures and Mechanical Properties of the Partially Melted Zone in the Fusion Welded Joints of 2219 Aluminum Alloy, Mater. Sci. Eng. A, 2015, 623, p 38–48

Acknowledgments

This work was financially supported by the Joint Funds of the National Natural Science Foundation of China (Grant No. U1637601).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, D., Li, Q., Zhao, Y. et al. Microstructure and Mechanical Properties of Three-Layer TIG-Welded 2219 Aluminum Alloys with Dissimilar Heat Treatments. J. of Materi Eng and Perform 27, 2938–2948 (2018). https://doi.org/10.1007/s11665-018-3394-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3394-7