Abstract

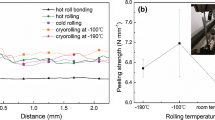

The Ti/Al laminate composites were prepared by hot pressing to investigate the forming performance due to the corresponding potential applications in both the aerospace and auto industry. The bonding interface morphology and element distributions were characterized by SEM and EDS. The phase constituent was detected by XRD. It was observed that these composites presented good bonding interfaces between Ti and Al layers, and no low-sized voids and intermetallic compounds formed at the interface. In addition, the formability of these laminate composites was studied by the uniaxial tension tests, the limit drawing ratio (LDR) and the forming limit curve (FLC) experiments, respectively. The results indicated that the flow stress increased along with the strain rate increment. A constitutive equation was developed for deformation behavioral description of these laminate composites. The LDR value was 1.8, and the most susceptible region to present cracks was located at the punch profile radius. The forming limit curve of the laminate composites was located between the curves of titanium and aluminum and intersected with the major strain line at approximately 0.31. The macroscopic cracks of the FLC sample demonstrated a saw-toothed crack feature.

Similar content being viewed by others

References

B. Zhang, Y. Kou, Y.Y. Xia, and X. Zhang, Modulation of Strength and Plasticity of Multiscale Ni/Cu Laminated Composites, Mater. Sci. Eng. A, 2015, 636, p 216–220

Y.E. Qi, Y.S. Zhang, and L.T. Hu, High-Temperature Self-lubricated Properties of Al2O3/Mo Laminated Composites, Wear, 2012, 280, p 1–4

R.O. Ritchie, The Conflicts Between Strength and Toughness, Nat. Mater., 2011, 10(11), p 817–822

K. Zhu, W.B. Yu, Y. Aman, and T. Jing, Synthesis, Microstructure and Mechanical Properties of a Bio-Inspired Ti-Intermetallic Multi-layered/SiCf-reinforced Ti-Matrix Hybrid Composite, J. Mater. Sci., 2016, 51(18), p 8747-8760

M.Y. Fan, J. Domblesky, K. Jin, L. Qin, S.Q. Cui, X.Z. Guo, N. Kim, and J. Tao, Effect of Original Layer Thicknesses on the Interface Bonding and Mechanical Properties of Ti-Al Laminate Composites, Mater. Des., 2016, 99, p 535–542

M. Ma, P. Huo, W.C. Liu, G.J. Wang, and D.M. Wang, Microstructure and Mechanical Properties of Al/Ti/Al Laminated Composites Prepared by Roll Bonding, Mater. Sci. Eng. A, 2015, 636, p 301–310

D.V. Lazurenko, I.A. Bataev, V.I. Mali, A.A. Bataev, I.N. Maliutina, V.S. Lozhkin, M.A. Esikov, and A.M.J. Jorge, Explosively Welded Multilayer Ti-Al Composites: Structure and Transformation During Heat Treatment, Mater. Des., 2016, 102, p 122–130

F.T. Kong, Y.Y. Chen, and D.L. Zhang, Interfacial Microstructure and Shear Strength of Ti–6Al–4V/TiAl Laminate Composite Sheet Fabricated by Hot Packed Rolling, Mater. Des., 2011, 32, p 3167–3172

M. Samavatian, A. Halvaee, A. Amadeh, and S. Zakipour, Microstructure and Mechanical Properties of Al2024/Ti-6Al-4V Transient Liquid Phase Bonded Joint, J. Mater. Eng. Perform., 2015, 24(6), p 2526–2534

S. Chatterjee, A. Sinha, D. Das, S. Ghosh, and A. Basumallick, Microstructure and Mechanical Properties of Al/Fe-aluminide In situ Composite Prepared by Reactive Stir Casting Route, Mater. Sci. Eng. A, 2013, 578, p 6–13

A. Dziadoń, R. Mola, and L. Błaż, Formation of Layered Mg/eutectic Composite Using Diffusional Processes at the Mg-Al Interface, Arch. Metal. Mater., 2011, 56(3), p 677–684

P.J. Lee, A.A. Squitieri, D.C. Larbalestier, T. Takeuchi, N. Banno, T. Fukuzaki, and H. Wada, Microchemical and Microstructural Comparison of High Performance Nb3Al Composites, IEEE Trans. Appl. Supercond., 2003, 13(2), p 3398–3401

Y. Guo, G. Liu, H. Jin, Z. Shi, and G. Qiao, Intermetallic Phase Formation in Diffusion-Bonded Cu/Al Laminates, J. Mater. Sci., 2011, 46(8), p 2467–2473

M. Konieczny, Processing and Microstructural Characterisation of Laminated Ti-Intermetallic Composites Synthesised Using Ti and Cu Foils, Mater. Lett., 2008, 62(17), p 2600–2602

I.A. Bataev, A.A. Bataev, V.I. Mali, and D.V. Pavliukovaa, Structural and Mechanical Properties of Metallic–Intermetallic Laminate Composites Produced by Explosive Welding and Annealing, Mater. Des., 2012, 35, p 225–234

J.P. Liu, L.S. Luo, Y.Q. Su, Y.J. Xu, X.Z. Li, R.R. Chen, J.J. Guo, and H.Z. Fu, Numerical Simulation of Intermediate Phase Growth in Ti/Al Alternate Foils, Trans. Nonferr. Met. Soc., 2011, 21(3), p 598–603

X. Wu, Review of Alloy and Process Development of TiAl Alloys, Intermetallics, 2006, 14(10), p 1114–1122

K. Kothari, R. Radhakrishnan, and N.M. Wereley, Advances in Gamma Titanium Aluminides and Their Manufacturing Techniques, Prog. Aerosp. Sci., 2012, 55, p 1–16

J.P. Liu, Y.Q. Su, L.S. Luo, H. Chen, Y.J. Xu, J.J. Guo, and H.Z. Fu, Fabrication of Wavy γ-TiAl Based Sheet with Foil Metallurgy, Trans. Nonferr. Met. Soc., 2012, 22(1), p 72–77

L.I. Duarte, F. Viana, A.S. Ramos, M.T. Vieira, C. Leinenbach, U.E. Klotz, and M.F. Vieira, Diffusion Bonding of γ-TiAl Using Modified Ti/Al Nanolayers, J. Alloy. Compd., 2012, 536, p 424–427

R.K. Gupta, B. Pant, and P.P. Sinha, Theory and Practice of γ + α2Ti Aluminide: A Review, Trans. Indian Met., 2014, 67(2), p 143–165

A.H. Assari and B. Eghbali, Interfacial Layers Evolution During Annealing in Ti-Al Multi-laminated Composite Processed Using Hot Press and Roll Bonding, Met. Mater. Int., 2016, 22(5), p 915–923

H.L. Yu, C. Lu, A.K. Tieu, H.J. Li, A. Godbole, and C.L. Kong, Annealing Effect on Microstructure and Mechanical Properties of Al/Ti/Al Laminate Sheets, Mater. Sci. Eng. A, 2016, 660, p 159–204

D.E. Alman, J.A. Hawk, A.V. Petty, Jr., and J.C. Rawers, Processing Intermetallic Composites by Self-propagating, High-Temperature Synthesis, JOM, 1994, 46(3), p 31–35

F. Kong, Y. Chen, and D. Zhang, Interfacial Microstructure and Shear Strength of Ti-6Al-4V/TiAl Laminate Composite Sheet Fabricated by Hot Packed Rolling, Mater. Des., 2011, 32(6), p 3167–3172

J. Liu, Y. Su, Y. Xu, L. Luo, J. Guo, and H. Fu, First Phase Selection in Solid Ti/Al Diffusion Couple, Rare Met. Mater. Eng., 2011, 40, p 753–756

Y. Wei, W. Aiping, Z. Guisheng, and R. Jialie, Formation Process of the Bonding Joint in Ti/Al Diffusion Bonding, Mater. Sci. Eng. A, 2008, 480, p 456–463

L. Xu, Y.Y. Cui, Y.L. Hao, and R. Yang, Growth of Intermetallic Layer in Multi-laminated Ti/Al Diffusion Couples, Mater. Sci. Eng. A, 2006, 435–436, p 638–647

Y.B. Sun, Y.Q. Zhao, D. Zhang, C.Y. Liu, H.Y. Diao, and C.L. Ma, Multilayered Ti-Al Intermetallic Sheets Fabricated by Cold Rolling and Annealing of Titanium and Aluminum Foils, Trans. Nonferr. Met. Soc., 2011, 21, p 1722–1727

Y.B. Sun, M.W. Liu, S.J. Ge, F.M. Ma, and C.L. Ma, Preparation of Multilayered Ti-Al Alloys by Solid Reaction, Mater. Sci. Forum, 2013, 747–748, p 1–8

Y. Du, G.H. Fan, T.B. Yu, N. Hansen, L. Geng, and X.X. Huang, Laminated Ti-Al Composites: Processing, Structure and Strength, Mater. Sci. Eng. A, 2016, 673, p 572–580

F.K. Chen and K.H. Chiu, Stamping Formability of Pure Titanium Sheets, Mater. Process. Technol., 2005, 170, p 181–186

O.M. Badr, B. Rolfe, P. Hodgson, and M. Weiss, Forming of High Strength Titanium Sheet at Room Temperature, Mater. Des., 2015, 66, p 618–626

L.F. Li, Z. Zhang, and G.T. Shen, Effect of Grain Size on the Tensile Deformation Mechanisms of Commercial Pure Titanium as Revealed by Acoustic Emission, JMEP, 2015, 24, p 1975–1986

J. Kachera and I.M. Robertson, In situ TEM Characterisation of Dislocation Interactions in α-titanium, Philos. Mag., 2016, 96(14), p 1437–1447

A.S. Khan and H. Liu, Strain Rate and Temperature Dependent Fracture Criteria for Isotropic and Anisotropic Metals, Int. J. Plast., 2012, 37, p 1–15

X. Tian and Y. Zhang, Mathematical Description for Flow Curves of Some Stable Austenitic Steels, Mater. Sci. Eng. A, 1994, 174(1), p 1–3

Acknowledgments

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (No. 51475231), a Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions, the Funding of Jiangsu Innovation Program for Graduate Education (No. KYLX_0263), Foundation of Graduate Innovation Center in NUAA (kfjj20150606) and the Fundamental Research Funds for the Central Universities (No. 20150027).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, L., Wang, H., Cui, S. et al. Characterization and Formability of Titanium/Aluminum Laminate Composites Fabricated by Hot Pressing. J. of Materi Eng and Perform 26, 3579–3587 (2017). https://doi.org/10.1007/s11665-017-2785-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2785-5