Abstract

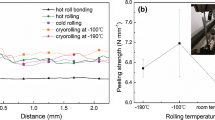

Ti-6Al-4V/Al 3003/Ti-6Al-4V laminated composites were fabricated by hot roll bonding. The microstructure and mechanical properties of the Ti/Al/Ti laminated composites were investigated. The Ti/Al/Ti laminated composites exhibited a good Ti/Al interfacial bonding with straight interface. The development of microstructure through the thickness of Al layer was inhomogeneous. The initial grains in the region near the interface of Al/Ti were markedly fragmented into equiaxed fine grains, whereas the grains in the center of Al layer were markedly elongated along the rolling direction. The inhomogeneity of deformation through the thickness of Al layer can be attributed to the effect of the uncoordinated deformation between Al and Ti layers and the inhomogeneity of initial microstructure. For the Ti/Al/Ti laminated composites fabricated with approximately 37% reduction, the UTS and YS increased with increasing rolling temperature, while the EL increased slightly. For the Ti/Al/Ti laminated composites fabricated at 400 °C, the UTS and YS increased significantly with increasing rolling reduction, whereas the EL decreased. The bonding strength increased with increasing rolling temperature and reduction.

Similar content being viewed by others

References

J. Wadsworth and D.R. Lesuer, Ancient and Modern Laminated Composites-from the Great Pyramid of Gizeh to Y2K, Mater. Charact., 2000, 45(4–5), p 289–313

H.S. Liu, B. Zhang, and G.P. Zhang, Enhanced Toughness and Fatigue Strength of Cold Roll Bonded Cu/Cu Laminated Composites with Mechanical Contrast, Scripta Mater., 2011, 65(10), p 891–894

W.A. Spitzig, A.R. Pelton, and F.C. Laabs, Characterization of the Strength and Microstructure of Heavily Cold Worked Cu-Nb Composites, Acta Metall., 1987, 35(10), p 2427–2442

F. Carreño, J. Chao, M. Pozuelo, and O.A. Ruano, Microstructure and Fracture Properties of an Ultrahigh Carbon Steel-Mild Steel Laminated Composite, Scripta Mater., 2003, 48(8), p 1135–1140

J.G. Luo and V.L. Acoff, Using Cold Roll Bonding and Annealing to Process Ti/Al Multi-Layered Composites from Elemental Foils, Mater. Sci. Eng., A, 2004, 379(1–2), p 164–172

J. Peng, Z. Liu, P. Xia, M. Lin, and S. Zeng, On the Interface and Mechanical Property of Ti/Al-6% Cu-0.5% Mg-0.4% Ag Bimetal Composite Produced by Cold-Roll Bonding and Subsequent Annealing Treatment, Mater. Lett., 2012, 74(5), p 89–92

M. Ma, P. Huo, W.C. Liu, G.J. Wang, and D.M. Wang, Microstructure and Mechanical Properties of Al/Ti/Al Laminated Composites Prepared by Roll Bonding, Mater. Sci. Eng., A, 2015, 636, p 301–310

M. Eizadjou, H.D. Manesh, and K. Janghorban, Investigation of Roll Bonding Between Aluminum Alloy Strips, Mater. Des., 2008, 29(4), p 909–913

L. Zhang, L. Meng, S.P. Zhou, and F.T. Yang, Behaviors of the Interface and Matrix for the Ag/Cu Bimetallic Laminates Prepared by Roll Bonding and Diffusion Annealing, Mater. Sci. Eng., A, 2004, 371(1–2), p 65–71

J.M. Lee, B.R. Lee, and S.B. Kang, Control of Layer Continuity in Metallic Multilayers Produced by Deformation Synthesis Method, Mater. Sci. Eng., A, 2005, 406(1–2), p 95–101

M. Movahedi, A.H. Kokabi, and S.M.S. Reihani, Investigation on the Bond Strength of Al-1100/St-12 Roll Bonded Sheets, Optimization and Characterization, Mater. Des., 2011, 32(6), p 3143–3149

X. Li, G. Zu, M. Ding, Y. Mu, and P. Wang, Interfacial Microstructure and Mechanical Properties of Cu/Al Clad Sheet Fabricated by Asymmetrical Roll Bonding and Annealing, Mater. Sci. Eng., A, 2011, 529, p 485–491

G. Heness, R. Wuhrer, and W.Y. Yeung, Interfacial Strength Development of Roll-Bonded Aluminium/Copper Metal Laminates, Mater. Sci. Eng., A, 2008, 483–484, p 740–742

X. Li, G. Zu, and P. Wang, Effect of Strain Rate on Tensile Performance of Al/Cu/Al Laminated Composites Produced by Asymmetrical Roll Bonding, Mater. Sci. Eng., A, 2013, 575, p 61–64

M. Movahedi, H.R. Madaah-Hosseini, and A.H. Kokabi, The Influence of Roll Bonding Parameters on the Bond Strength of Al-3003/Zn Soldering Sheets, Mater. Sci. Eng., A, 2008, 487, p 417–423

M. Abbasi and M.R. Toroghinejad, Effects of Processing Parameters on the Bond Strength of Cu/Cu Roll-Bonded Strips, J. Mater. Process. Technol., 2010, 210(3), p 560–563

H. Chang, M.Y. Zheng, C. Xu, G.D. Fan, H.G. Brokmeier, and K. Wu, Microstructure and Mechanical Properties of the Mg/Al Multilayer Fabricated by Accumulative Roll Bonding (ARB) at Ambient Temperature, Mater. Sci. Eng., A, 2012, 543, p 249–256

R. Jamaati and M.R. Toroghinejad, Effect of Friction, Annealing Conditions and Hardness on the Bond Strength of Al/Al Strips Produced by Cold Roll Bonding Process, Mater. Des., 2010, 31(9), p 4508–4513

R. Jamaati and M.R. Toroghinejad, Investigation of the Parameters of the Cold Roll Bonding (CRB) Process, Mater. Sci. Eng., A, 2010, 527, p 2320–2326

H. Yan and J.G. Lenard, A Study of Warm and Cold Roll-Bonding of an Aluminium Alloy, Mater. Sci. Eng., A, 2004, 385, p 419–428

J. Inoue, S. Nambu, Y. Ishimoto, and T. Koseki, Fracture Elongation of Brittle/Ductile Multilayered Steel Composites with a Strong Interface, Scripta Mater., 2008, 59(10), p 1055–1058

S. Nambu, M. Michiuchi, J. Inoue, and T. Koseki, Effect of Interfacial Bonding Strength on Tensile Ductility of Multilayered Steel Composites, Compos. Sci. Technol., 2009, 69(11–12), p 1936–1941

K.S. Lee, H.Y. Dong, H.K. Kim, Y.N. Kwon, and Y.S. Lee, Effect of Annealing on the Interface Microstructure and Mechanical Properties of a STS-Al-Mg 3-ply Clad Sheet, Mater. Sci. Eng., A, 2012, 556, p 319–330

M. Masoumi and E. Emadoddin, Interface Characterization and Formability of Two and Three-Layer Composite Sheets Manufactured by Roll Bonding, Mater. Des., 2013, 44, p 392–396

M. Pozuelo, F. Carreño, and O.A. Ruano, Delamination Effect on the Impact Toughness of an Ultrahigh Carbon-Mild Steel Laminate Composite, Compos. Sci. Technol., 2006, 66(15), p 2671–2676

S.L. Semiatin and H.R. Piehler, Formability of Sandwich Sheet Materials in Plane Strain Compression and Rolling, Metall. Mater. Trans. A, 1978, 10(1), p 97–107

D. Yang, P. Cizek, P. Hodgson, and C. Wen, Ultrafine Equiaxed-Grain Ti/Al Composite Produced by Accumulative Roll Bonding, Scripta Mater., 2010, 62(5), p 321–324

X. Sauvage, G.P. Dinda, and G. Wilde, Non-Equilibrium Intermixing and Phase Transformation in Severely Deformed Al/Ni Multilayers, Scripta Mater., 2007, 56(3), p 181–184

C.Y. Chung, M. Zhu, and C.H. Man, Effect of Mechanical Alloying on the Solid State Reaction Processing of Ni-36.5 at.% Al Alloy, Intermetallics, 2002, 10(9), p 865–871

M. Pozuelo, F. Carreño, M. Carsí, and O.A. Ruano, Influence of Interfaces on the Mechanical Properties of Ultrahigh Carbon Steel Multilayer Laminates, Int. J. Mater. Res., 2007, 98(1), p 47–52

D.R. Lesuer, C.K. Syn, O.D. Sherby, J. Wadsworth, J.J. Lewandowski, and W.H. Hunt, Mechanical Behaviour of Laminated Metal Composites, Int. Mater. Rev., 1995, 41(5), p 169–197

S. Lee, J. Wadsworth, and O.D. Sherby, Tensile Properties of Laminated Composites Based on Ultrahigh Carbon Steel, J. Compos. Mater., 1991, 25(7), p 842–853

K.S. Lee, J.S. Kim, Y.M. Jo, S.E. Lee, J. Heo, Y.W. Chang, and Y.S. Lee, Interface-correlated Deformation Behavior of a Stainless Steel-Al-Mg 3-ply Composite, Mater. Charact., 2013, 75, p 138–149

L. Ghalandari, M.M. Mahdavian, and M. Reihanian, Microstructure Evolution and Mechanical Properties of Cu/Zn Multilayer Processed by Accumulative Roll Bonding (ARB), Mater. Sci. Eng., A, 2014, 593, p 145–152

N.L. Dong and Y.K. Kim, Tensile Properties of Stainless Steel-Clad Aluminium Sandwich Sheet Metals, J. Mater. Sci., 1988, 23(4), p 1436–1442

B.X. Liu, L.J. Huang, B. Wang, and L. Geng, Effect of Pure Ti Thickness on the Tensile Behavior of Laminated Ti-TiBw/Ti Composites, Mater. Sci. Eng., A, 2014, 617, p 115–120

H.S. Liu, B. Zhang, and G.P. Zhang, Delaying Premature Local Necking of High-Strength Cu: A Potential Way to Enhance Plasticity, Scripta Mater., 2011, 64(1), p 13–16

X.L. Ma, C.X. Huang, W.Z. Xu, H. Zhou, X.L. Wu, and Y.T. Zhu, Strain Hardening and Ductility in a Coarse-Grain/Nanostructure Laminate Material, Scripta Mater., 2015, 103, p 57–60

H.A. Mohamed and J. Washburn, Mechanism of Solid State Pressure Welding, Weld. J., 1975, 55, p 302s–310s

L.R. Vaidyanath, M.G. Nicholas, and D.R. Milner, Pressure Welding by Rolling, Br. Weld. J., 1959, 6, p 13–28

J.A. Cave and J.D. Williams, The Mechanism of Cold Pressure Welding by Rolling, J. Inst. Metals, 1973, 101(7), p 203–207

H. Granjun, Fundamental of Welding Metallurgy, Abington Publishing, Cambridge, 1991

J.M. Parks, Recrystallization Welding, Weld. J., 1953, 32(5), p 209s–221s

J. Cave, The Mechanism of Cold Pressure Welding by Rolling, J. Inst. Met., 1973, 101(7), p 203–207

W.C. Sherwood and D.R. Milner, The Effect of Vacuum Machining on the Cold Welding of Some Metals, J. Inst. Met., 1969, 97(1), p 1–5

X.K. Peng, G. Heness, and W.Y. Yeung, Effect of Rolling Temperature on Interface and Bond Strength Development of Roll Bonded Copper/Aluminium Metal Laminates, J. Mater. Sci., 1999, 34(2), p 277–281

M. Eizadjou, H.D. Manesh, and K. Janghorban, Mechanism of Warm and Cold Roll Bonding of Aluminum Alloy Strips, Mater. Des., 2009, 30(10), p 4156–4161

S.A. Hosseini, M. Hosseini, and H.D. Manesh, Bond Strength Evaluation of Roll Bonded Bi-layer Copper Alloy Strips in Different Rolling Conditions, Mater. Des., 2011, 32(1), p 76–81

J. Yong, P. Dashu, L. Dong, and L. Luoxing, Analysis of Clad Sheet Bonding by Cold Rolling, J. Mater. Process. Technol., 2000, 105(1–2), p 32–37

G.Y. Tzou and M.N. Huang, Analytical Modified Model of the Cold Bond Rolling of Unbounded Double-Layers Sheet Considering Hybrid Friction, J. Mater. Process. Technol., 2003, 140(1–3), p 622–627

A. Shabani, M.R. Toroghinejad, and A. Shafyei, Effect of Post-Rolling Annealing Treatment and Thickness of Nickel Coating on the Bond Strength of Al-Cu Strips in Cold Roll Bonding Process, Mater. Des., 2012, 40, p 212–220

Acknowledgments

This work was supported by the National High Technology Research and Development Program of China (863 Program, No. 2013AA031304).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, M., Meng, X. & Liu, W.C. Microstructure and Mechanical Properties of Ti/Al/Ti Laminated Composites Prepared by Hot Rolling. J. of Materi Eng and Perform 26, 3569–3578 (2017). https://doi.org/10.1007/s11665-017-2769-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2769-5