Abstract

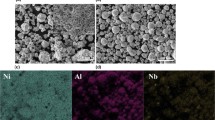

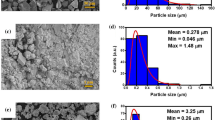

In the present investigation, the effects of compaction load and sintering temperature on the tribological and mechanical behavior of Ni/20%SiC/7%MoS2 hybrid composites was studied. The density, compression strength, and hardness of the composites were evaluated and compared. The wear properties of the composites were evaluated for the test condition of 1 m/s speed and 10 N load using a pin-on-disk tribometer. The braking performance of the composites was evaluated in a subscale dynamometer for the 500 kJ energy condition. The microstructure and wear surface morphology of the composites were analyzed by stereo, optical, and scanning electron microscopes. From the results, the following important conclusions are drawn: (1) the compaction load of 1400 kN and sintering temperature of 900 °C are optimum to obtain the best combination of tribological and mechanical properties; (2) the properties such as density, compression strength, hardness, wear, and friction increase up to a critical sintering temperature, and then decrease later; (3) the composition and thickness of the interface reaction product phases (Ni2Si, Ni3Si, and graphite) play a key role in deciding the strength of Ni/SiC interface that consequently affects the mechanical and tribological properties of the composites; (4) the abrasive wear is found to be the main wear mechanism in the highly densified composites, whereas the delamination wear and the third-body wear are major wear mechanisms in the poorly densified composites; and (5) the better braking performance of the highly densified composites is attributed to the absence of third-body wear, controlled flow of solid lubricant, and lower porosity.

Similar content being viewed by others

References

Y. Sahin, Abrasive Wear Behavior of SiC/2014 Aluminum Composite, Tribol. Int., 2010, 43, p 939–943

W.D. Callister, Materials Science and Engineering an Introduction, 2nd ed., Wiley, New York, 2007, p 791

T. Lim, Y.H. Kim, C.S. Lee, and K.S. Han, Fabrication and Mechanical Properties of Aluminum Matrix Composite Materials, J. Compos. Mater., 1992, 26, p 1062–1086

S.F. Moustafa, Z.A. Hamid, and A.M. Abd-Elhay, Copper Matrix SiC and Al2O3 Particulate Composites by Powder Metallurgy Technique, Mater. Lett., 2002, 53, p 244–249

A.M. Hassan, A. Alrashdan, M.T. Hayajneh, and T.M. Ahmad, Wear Behavior of Al-Mg-Cu-Based Composites Containing SiC Particles, Tribol. Int., 2009, 42, p 1230–1238

S.Y. Zhang and S.S. Feng, Friction and Wear Performances of Brake Material Dry Sliding Against a Composite with a Semi-Interpenetrating Network Structure of Ceramics and Al-Alloy, Tribol. Int., 2011, 44, p 248–257

D. Aidun, P. Martin, and J. Sun, Fracture and Mechanical Properties of P100 Gr/6061 Al Composite, J. Mater. Eng. Perform., 1992, 1, p 615–624

T.R. Prabhu, V.K. Varma, and S. Vedantam, Dry Sliding Wear of Layered Fe/SiC Composites for Aircraft Braking Applications, J. Mater. Eng. Perform., 2014, 23(10), p 3666–3679

T.R. Prabhu and S. Vedantam, Layer Graded Cu/B4C/Graphite Hybrid Composites: Processing, Characterization and Evaluation of Its Mechanical and Wear Behavior, Tribol. Trans., 2015, 58(4), p 718–728

M. Chandrasekaran and P. Singh, Sintered Iron-Based Antifriction Materials with Added β-SiC, Wear, 1997, 206, p 1–7

R.N. Rao, S. Das, D. Mondal, G. Dixit, and S.L. Tulasi, Dry Sliding Wear Maps for AA7010 (Al-Zn-Mg-Cu) Aluminium Matrix Composite, Tribol. Int., 2013, 60, p 77–82

A. Luo, Processing, Microstructure and Mechanical Behavior of Cast Magnesium Metal Matrix Composites, Metall. Mater. Trans. A, 1995, 26, p 2445–2455

S. Fu and H. Xu, Microstructure and Wear Behavior of (Ti, V)C Reinforced Ferrous Composite, J. Mater. Eng. Perform., 2010, 19, p 825–828

M. Nosonovsk and P.K. Rohatgi, Biomimetics in Materials Science: Self healing, Self-lubricating and Self-cleaning Materials, Springer, New York, 2012, p 451

S. Das, K. Das, and S. Das, Abrasive Wear Behavior of Al-4.5 wt% Cu/(Zircon Sand + Silicon Carbide) Hybrid Composite, J. Compos. Mater., 2009, 43, p 2665–2672

H. Tang, X. Zeng, Z. Xiong, L. Long, and Z. Jizhao, Mechanical and Tribological Properties of Short-Fiber-Reinforced SiC Composites, Tribol. Int., 2009, 42, p 823–827

L. Liu, H. Zhao, W. Hu, and B. Shen, Analysis of Tensile Strength and Microstructure of Ni-SiC Composites Prepared by Electroforming, Mater. Lett., 2005, 59, p 3014–3017

F.X. Wang, Y.X. Wu, Y.Q. Cheng, B. Wang, and D. Steven, Effects of Solid Lubricant MoS2 on the Tribological Behavior Of Hot-Pressed Ni/MoS2 Self-lubricating Composites at Elevated Temperatures, Tribol. Trans., 1996, 39(2), p 392–397

W.O. Winer, Molybdenum Disulphide as a Lubricant: A Review of the Fundamental Knowledge, Wear, 1967, 10, p 422–452

L. Zhang, J. Xiao, and K. Zhou, Sliding Wear Behavior of Silver-Molybdenum Disulfide Composite, Tribol. Trans., 2012, 55(4), p 473–480

Y. Wu, H. Liu, B. Shen, L. Liu, and W. Hu, The Friction and Wear of Electroless Ni-P Matrix with PTFE and/or SiC Particles Composite, Tribol. Int., 2006, 39, p 553–559

Y. Wu, B. Shen, L. Liu, and W. Hu, The Tribological Behaviour of Electroless Ni-P-Gr-SiC Composite, Wear, 2006, 261, p 201–207

A. Grosjean, M. Rezrazi, J. Takadoum, and P. Bercot, Hardness, Friction and Wear Characteristics of Nickel-SiC Electroless Composite Deposits, Surf. Coat. Technol., 2001, 137, p 92–96

P. Narasimman, M. Pushpavanam, and V.M. Periasamy, Wear and Scratch Resistance Characteristics of Electrodeposited Nickel-Nano and Micro SiC Composites, Wear, 2012, 292–293, p 197–206

A. Aal, K.M. Ibrahim, and Z.D. Hamid, Enhancement of Wear Resistance of Ductile Cast Iron by Ni-SiC Composite Coating, Wear, 2006, 260, p 1070–1075

T.R. Prabhu, V. Varma, and S. Vedantam, Effect of Reinforcement Type, Size, and Volume Fraction on the Tribological Behaviour of Fe Matrix Composites at High Sliding Speed Conditions, Wear, 2014, 309(1–2), p 247–255

T.R. Prabhu, V.K. Varma, and S. Vedantam, Effect of SiC Volume Fraction and Size on Dry Sliding Wear of Fe/SiC/Graphite Hybrid Composites for High Sliding Speed Applications, Wear, 2014, 309(1–2), p 1–10

Y. Cao and L. Nyborg, Contact Formation on Silicon Carbide by Use of Nickel and Tantalum from a Materials Science Point of View, Properties and Applications of Silicon Carbide, R. Gerhardt, Ed., InTech, Rijeka, 2011, p 171–194

A. Kestle, S.P. Wilks, A. Koh, C. Wright, and P.A. Mawk, Comparative Surface Studies on Wet and Dry Sacrificial Thermal Oxidation on Silicon Carbide, Mater. Sci. Forum, 2000, 338, p 1025–1028

A. Ohi, J. Labis, Y. Morikawa, T. Fujiki, M. Hirai, M. Kusaka, and M. Iwami, Soft X-ray Emission Study of Thermally Treated Ni(film)/4H-SiC(Substrate) Interface, Appl. Surf. Sci., 2002, 190, p 366–370

M. Bachli, M.A. Nicolet, L. Baud, C. Jaussaud, and R. Madar, Nickel Film on (001) SiC: Thermally Induced Reactions, Mater. Sci. Eng. B, 1998, B56, p 11–23

D.C. Lou, O.M. Akselsen, J.K. Solberg, O. Morten, J. Breget, and N. Dahl, Silicon-Boronising of Nimonic 90 Superalloy, Surf. Coat. Technol., 2006, 200, p 3582–3589

X.D. Lu and H.M. Wang, High-Temperature Phase Stability and Tribological Properties of Laser Clad Mo2N3Si/NiSi Metal Silicide Coatings, Acta Mater., 2004, 52, p 5419–5426

C. Sun, R. Shen, and M. Song, Effects of Sintering and Extrusion on the Microstructures and Mechanical Properties of a SiC/Al-Cu Composite, Mater. Eng. Perform., 2012, 21, p 373–381

S. Tiwari, P. Rajput, and S. Srivastava, Densification Behaviour in the Fabrication of Al-Fe Metal Matrix Composite Using Powder Metallurgy Route, ISRN Metall., 2012, 1, p 211–217

J. Zhu, L. Liu, B. Shen, and W. Hu, Mechanical Properties of Cu/SiCp Composites Fabricated by Composite Electroforming, Mater. Lett., 2007, 61, p 2804–2809

T.S. Marinova, V. Krastev, C. Hallic, R. Yakimova, and E. Janzen, Interface Chemistry and Electric Characterization of Nickel Metallization on 6H-SiC, Appl. Surf. Sci., 1996, 99, p 119–125

Y. Du and J.C. Schuster, Experimental Investigations and Thermodynamic Descriptions of the Ni-Si and C-Ni-Si Systems, Metall. Mater. Trans. A, 1999, 30A, p 2409–2418

V.L. Litvinov, K.D. Demakov, O.A. Agueev, A.M. Svetlichyi, R. Konakova, and M. Peter, Investigation of the Effect of Rapid Thermal Annealing Modes on the Parameters of Ni/21R-SiC Contact, Mater. Sci. Forum, 2002, 389–393, p 905–908

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24, p 981–988

P.J. Blau, ASM Handbook-Vol 18-Friction, Lubrication and Wear Technology, ASM International, Materials Park, 1992, p 942

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prabhu, T.R. Effect of Compaction Load and Sintering Temperature on Tribological and Mechanical Behavior of Ni/SiC/MoS2 Composites. J. of Materi Eng and Perform 25, 1436–1445 (2016). https://doi.org/10.1007/s11665-016-1994-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1994-7