Abstract

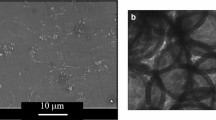

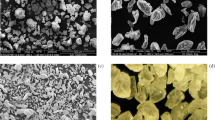

In this study, beta-type Ti-35Nb-10Cu alloy foams were produced by powder metallurgy method for dental implant applications. 35% Nb was added to stabilize the beta-Ti phase with low Young’s modulus. Cu addition enhanced sinterability and gave precipitation hardening capacity to the alloy. Sintered specimens were precipitation hardened in order to enhance the mechanical properties. Electrochemical corrosion behavior of the specimens was examined by electrochemical impedance spectroscopy in artificial saliva. Electrochemical impedance spectroscopy results indicated that the oxide film on the surface of foam is a bi-layer structure consisting of outer porous layer and inner barrier layer. Impedance values of barrier layer were higher than porous layer. Corrosion resistance of specimens decreased at high fluoride concentrations and at low pH of artificial saliva. Corrosion resistance of alloys was slightly decreased with aging. Mechanical properties, microstructure, and surface roughness of the specimens were also examined.

Similar content being viewed by others

References

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, and H.N.G. Wadley, Metal Foams: A Design Guide, Elsevier Science, Boston, 2000

L.J. Gibson and M.F. Ashby, Cellular Solids-Structures and Properties, 2nd ed., Cambridge University Press, Cambridge, 1997

N. Wenjuan, B. Chenguang, Q. GuiBao, and W. Qiang, Processing and Properties of Porous Titanium Using Space Holder Technique, Mater. Sci. Eng. A, 2009, 506, p 148–151

I. Mutlu and E. Oktay, Characterization of 17-4 PH Stainless Steel Foam for Biomedical Applications in Simulated Body Fluid and Artificial Saliva, Mater. Sci. Eng. C, 2013, 33, p 1125–1131

L.J. Gibson, Biomechanics of Cellular Solids, J. Biomech., 2005, 38, p 377–399

J.G. Lin, Y.C. Li, C.S. Wong, P.D. Hodgson, and C.E. Wen, Degradation of the Strength of Porous Titanium After Alkali and Heat Treatment, J. Alloy Compd., 2009, 485, p 316–319

J. Huang, H. Xing, and J. Sun, Structural Stability and Generalized Stacking Fault Energies in β Ti–Nb Alloys: Relation to Dislocation Properties, Scripta Mater., 2012, 66, p 682–685

Q. Wei, L. Wang, Y. Fu, J. Qin, W. Lu, and D. Zhang, Influence of Oxygen Content on Microstructure and Mechanical Properties of Ti-Nb-Ta-Zr Alloy, Mater. Des., 2011, 32, p 2934–2939

S.A. Souza, R.B. Manicardi, P.L. Ferrandini, C.R.M. Afonso, A.J. Ramirez, and R. Caram, Effect of the Addition of Ta on Microstructure and Properties of Ti–Nb Alloys, J. Alloy Compd., 2010, 504, p 330–340

D.C. Zhang, Y.F. Mao, Y.L. Li, J.J. Li, M. Yuan, and J.G. Lin, Effect of Ternary Alloying Elements on Microstructure and Superelastictity of Ti-Nb Alloys, Mater. Sci. Eng. A, 2013, 559, p 706–710

E.S.N. Lopes, A. Cremasco, C.R.M. Afonso, and R. Caram, Effects of Double Aging Heat Treatment on the Microstructure, Vickers Hardness and Elastic Modulus of Ti-Nb Alloys, Mater. Charact., 2011, 62, p 673–680

Z.C. Zhou, J.Y. Xiong, S.Y. Gu, D.K. Yang, Y.J. Yan, and J. Du, Anelastic Relaxation Caused by Interstitial Atoms in β-type Sintered Ti–Nb Alloys, J. Alloy Compd., 2011, 509, p 7356–7360

W. Xiao-jun, Effects of Alkali and Heat Treatment on Strength of Porous Ti35Nb, Trans. Nonferrous Met. Soc. China, 2011, 21, p 1335–1339

V. Raman, S. Nagarajan, and N. Rajendran, Electrochemical Impedance Spectro-Scopic Characterisation of Passive Film Formed Over Ti-29Nb-13Ta-4.6Zr Alloy, Electrochem. Commun., 2006, 8, p 1309–1314

B.L. Wang, Y.F. Zheng, and L.C. Zhao, Electrochemical Corrosion Behavior of Biomedical Ti-22Nb and Ti-22Nb–6Zr Alloys in Saline Medium, Mater. Corros., 2009, 60(10), p 788–794

A. Cremasco, W.R. Osorio, C.M.A. Freire, A. Garcia, and R. Caram, Electrochemicalcorrosion Behavior of a Ti-35Nb Alloy for Medical Prostheses, Electrochim. Acta, 2008, 53, p 4867–4874

X. Yao, Q.Y. Sun, L. Xiao, and J. Sun, Effect of Ti2Cu Precipitates on Mechanical Behavior of Ti–2.5Cu Alloy Subjected to Different Heat Treatments, J. Alloy Compd., 2009, 484, p 196–202

F.F. Cardoso, A. Cremasco, R.J. Contieri, E.S.N. Lopes, C.R.M. Afonso, and R. Caram, Hexagonal Martensite Decomposition and Phase Precipitation in Ti-Cu Alloys, Mater. Des., 2011, 32, p 4608–4613

T. Luangvaranunt and P. Pripanapong, Pin-On-Disc Wear of Precipitation Hardened Titanium-Copper Alloys Fabricated by Powder Metallurgy, Mater. Trans., 2012, 53(3), p 518–523

T. Shirai, H. Tsuchiya, T. Shimizu, K. Ohtani, Y. Zen, and K. Tomita, Prevention of Pin Tract Infection with Titanium-Copper Alloys, J. Biomed. Mater. Res. B, 2009, 91, p 373–380

I. Gurappa, Characterisation of Different Materials for Corrosion Resistance Under Simulated Body Fluid Conditions, Mater. Charact., 2002, 49, p 73–79

J. Liu, F. Li, C. Liu, H. Wang, B. Ren, K. Yang, and E. Zhang, Effect of Cu Content on the Antibacterial Activity of Titanium-Copper Sintered Alloys, Mater. Sci. Eng. C, 2014, 35, p 392–400

T. Albrektsson and F. Isidor, Consensus Report of Session IV, Proceedings of the First European Workshop on Periodontology, N.P. Lang and T. Karring, Ed., Quintessence, London, 1994, p 365–369

T. Albrektsson and C. Johansson, Osteoinduction, Osteoconduction and Osseointegration, Eur. Spine J., 2001, 10, p 96–101

M. Yoshinari, Y. Oda, T. Kato, and K. Okuda, Influence of Surface Modifications to Titanium on Antibacterial Activity In Vitro, Biomaterials, 2001, 22, p 2043–2048

D. Mareci, R. Chelariu, I. Dan, D.M. Gordin, and T. Gloriant, Corrosion Behaviour of Ti20Mo Alloy in Artificial Saliva, J. Mater. Sci. Mater. Med., 2010, 21, p 2907–2913

M. Sharma, A.V.R. Kumar, N. Singh, N. Adya, and B. Saluja, Electrochemical Corrosion Behavior of Dental/Implant Alloys in Artificial Saliva, J. Mater. Eng. Perform., 2008, 17, p 695–701

W.F. Ho, S.C. Wu, C.W. Lin, and S.K.H.C. Hsu, Electrochemical Behavior of Ti-20Cr-X Alloys in Artificial Saliva Containing Fluoride, J. Appl. Electrochem., 2011, 41, p 337–343

Y. Oshida, C.B. Sellers, K. Mirza, and F. Farzin-Nia, Corrosion of Dental Materials by Dental Treatment Agents, Mater. Sci. Eng. C, 2005, 25, p 343–348

S. Kumar, T.S.N.S. Narayanan, and S.S. Kumar, Influence of Fluoride ion on the Electrochemical Behaviour of β-Ti Alloy for Dental Implant Application, Corros. Sci., 2010, 52, p 1721–1727

F. Xie, X. He, S. Cao, M. Mei, and X. Qu, Influence of Pore Characteristics on Microstructure, Mechanical Properties and Corrosion Resistance of Selective Laser Sintered Porous Ti–Mo Alloys for Biomedical Applications, Electrochim. Acta, 2013, 105, p 121–129

W.R. Osorio, A. Cremasco, P.N. Andrade, A. Garcia, and R. Caram, Electrochemical Behavior of Centrifuged Cast and Heat Treated Ti–Cu Alloys for Medical Applications, Electrochim. Acta, 2010, 55, p 759–770

A. Robin and J.P. Meirelis, Influence of Fluoride Concentration and pH on Corrosion Behavior of Titanium in Artificial Saliva, J. Appl. Electrochem., 2007, 37, p 511–517

J. Fojt, L. Joska, and J. Malek, Corrosion Behaviour of Porous Ti-39Nb Alloy for Biomedical Applications, Corros. Sci., 2013, 71, p 78–83

C. García, F. Martín, P. Tiedra, Y. Blanco, J.M.R. Roman, and M. Aparicio, Electrochemical Reactivation Methods Applied to PM Austenitic Stainless Steels Sintered in Nitrogen-Hydrogen Atmosphere, Corros. Sci., 2008, 50, p 687–697

I. Mutlu, Sinter-Coating Method for the Production of TiN-Coated Titanium Foam for Biomedical Implant Applications, Surf. Coat. Technol., 2013, 232, p 396–402

M. Nakagawa, S. Matsuya, and K. Udoh, Corrosion Behavior of Pure Titanium and Titanium Alloys in Fluoride-Containing Solutions, Dent. Mater. J., 2001, 20(4), p 305–314

Acknowledgments

This work was supported partially by Scientific Research Projects Coordination Unit of Istanbul University, Project Number 42922.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mutlu, I., Yeniyol, S. & Oktay, E. Production and Precipitation Hardening of Beta-Type Ti-35Nb-10Cu Alloy Foam for Implant Applications. J. of Materi Eng and Perform 25, 1586–1593 (2016). https://doi.org/10.1007/s11665-016-1982-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1982-y