Abstract

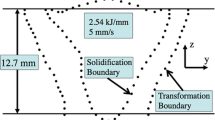

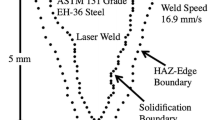

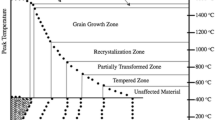

Aspects of a methodology for inverse thermal analysis of welds are examined that provide for relaxed model-parameter optimization. These aspects are associated with the inherent insensitivity of temperature fields, obtained by inverse analysis, to local shape variations of constrained boundaries within these fields. The inverse analysis methodology is in terms of numerical-analytical basis functions for construction parametric temperature histories, which can be adopted as input data to computational procedures for further analysis. In addition, these parametric temperature histories can be used for inverse thermal analysis of welds corresponding to other process parameters or welding processes whose process conditions are within similar regimes. The inverse thermal analysis procedure provides for the inclusion of volumetric constraint conditions whose two-dimensional projections are mappings onto transverse cross sections of experimentally measured boundary conditions, such as solidification and transformation boundaries, and isothermal surfaces associated with thermocouple measurements. Issues concerning relaxed parameter optimization are discussed with respect to inverse thermal analysis of Ti-6Al-4V pulsed-mode laser welds using multiple constraint conditions.

Similar content being viewed by others

References

D. Rosenthal, The Theory of Moving Sources of Heat and Its Application to Metal Treatments, Trans. ASME, 1946, 68, p 849–866

J. Goldak, A. Chakravarti, and M. Bibby, A New Finite Element Model for Welding Heat Source, Metall. Trans. B, 1984, 15, p 299–305

O. Grong, Metallurgical Modelling of Welding, Materials Modelling Series, 2 Ed., H.K.D.H. Bhadeshia, Ed., The Institute of Materials, UK, (1997), Chapter 2, p. 1–115.

R.O. Myhr and O. Grong, Dimensionless Maps for Heat Flow Analyses in Fusion Welding, Acta Metall. Mater., 1990, 38, p 449–460

R.C. Reed and H.K.D.H. Bhadeshia, A Simple Model For Multipass Welds, Acta Metall. Mater., 1994, 42(11), p 3663–3678

V.A. Karkhin, P.N. Homich and V.G. Michailov, Models for Volume Heat Sources and Functional-Analytic Technique for Calculating the Temperature Fields in Butt Welding, ‘Mathematical Modelling of Weld Phenomena’, Vol 8, Verlag der Technischen Universite Graz, Austria, 2007, p. 847.

A.A. Deshpande, A. Short, D.G. McCartney, and T.H. Hyde, Finite-Element Analysis of Experimentally Identified Parametric Envelopes for Stable Keyhole Plasma Arc Welding of a Titanium Alloy, J. Strain Anal. Eng. Des., 2012, 47(5), p 266–275

I.S. Leoveanu and G. Zgura, Modelling the Heat and Fluid Flow in the Welded Pool from High Power Arc Sources, Mater. Sci. Forum, 2008, 580–582, p 443–446. doi:10.4028/www.scientific.net/msf.580582.443

E.A. Metzbower, D.W. Moon, C.R. Feng, S.G. Lambrakos, and R.J. Wong, Modelling of HSLA-65 GMAW Welds, Mathematical Modelling of Weld Phenomena, 7, Verlag der Technischen Universite Graz, Austria, 2005, p 327–339

S.G. Lambrakos, R.W. Fonda, J.O. Milewski, and J.E. Mitchell, Analysis of Friction Stir Welds using Thermocouple Measurements, Sci.Technol. Weld. Join., 2003, 8, p 345

S.G. Lambrakos, A. Shabaev, and L. Huang, Inverse Thermal Analysis of a Titanium Laser Weld Using Multiple Constraint Conditions, J. Mater. Eng. Perform., 2014, 23(6), p 2233–2240. doi:10.1007/s11665-014-1021-9

R.W. Farebrother, Linear Least Square Computations, Marcel Dekker, New York, 1988

Y.B. Bard, Nonlinear Parameter Estimation, Academic Press, New York, 1974

K. Levenberg, A Method for the Solution of Certain Non-linear Problems in Least-Squares, Quart. Appl. Math, 1944, 2, p 164–168

D.W. Marquardt, An Algorithm for Least Squares Estimation of Nonlinear Parameters, J. Soc. Ind. Appl. Moth, 1963, II, p 431–441

A. Tarantola, Inverse Problem Theory and Methods for Model Parameter Estimation, SIAM, Philadelphia, 2005

M.N. Ozisik and H.R.B. Orlande, Inverse Heat Transfer, Fundamentals and Applications, Taylor and Francis, New York, 2000

K. Kurpisz and A.J. Nowak, Inverse Thermal Problems, Computational Mechanics Publications, Boston, 1995

O.M. Alifanov, Inverse Heat Transfer Problems, Springer, Berlin, 1994

J.V. Beck, B. Blackwell, and C.R. St, Clair, Inverse Heat Conduction: Ill-Posed Problems, Wiley Interscience, New York, 1985

J.V. Beck, Inverse Problems in Heat Transfer with Application to Solidification and Welding, Modeling of Casting, Welding and Advanced Solidification Processes V, M. Rappaz, M.R. Ozgu and K.W. Mahin Eds., The Minerals, Metals and Materials Society, 1991, p. 427–437.

J.V. Beck, Inverse Problems in Heat Transfer, Mathematics of Heat Transfer, G.E. Tupholme and A.S. Wood Eds., Clarendon Press, Oxford, (1998), p. 13–24.

S.G. Lambrakos and S.G. Michopoulos, Algorithms for Inverse Analysis of Heat Deposition Processes, Mathematical Modelling of Weld Phenomena, Vol. 8, Verlag der Technischen Universite Graz, Austria (2007), p. 847.

S.G. Lambrakos and J.O. Milewski, Analysis of Welding and Heat Deposition Processes using an Inverse-Problem Approach, Mathematical Modelling of Weld Phenomena, Vol. 7, Verlag der Technischen Universite Graz, Austria 2005, p. 1025–1055.

H.S. Carslaw and J.C. Jaegar, Conduction of Heat in Solids, Clarendon Press, Oxford, 2nd ed, 374, 1959.

A.M. Geoffrion, Duality in Nonlinear Programming: A Simplified Applications-Oriented Development, SIAM Rev., 1971, 13(1), p 1–37

E. Akman, A. Demir, T. Canel, and T. Sinmazcelik, Laser Welding of Ti6Al4V Titanium, J. Mater. Proc. Technol., 2009, 209, p 3705–3713

R. Rai, P. Burgardt, J.O. Milewski, T.J. Lienert, and T. DebRoy, Heat Transfer and Fluid Flow During Electron Beam Welding of 21Cr-6Ni-9Mn steel and Ti-6AL-4V alloy, J. Phys. D, 2009, 42, p 025503

R. Rai, J.W. Elmer, T.A. Palmer, and T. DebRoy, Heat Transfer and Fluid Flow During Keyhole Mode Laser Welding of Tantalum, Ti-6AL-4V, 304L Stainless Steel and Vanadium, J. Phys. D, 2007, 40, p 5753–5766

J.O. Milewski, Los Alamos National Laboratory (Ret.), Private Communication.

Y.K. Liu and Y.M. Zhang, Control of 3D Weld Pool Surface, Control Eng. Pract., 2013, 21(11), p 1469–1480

W.J. Zhang, Y.K.Kang and Y.M. Zhang, Real-Time Measurement of Three-Dimensional Weld Pool Surface in GTAW, Chapter 14, Welding Processes, R. Kovacevic, InTech, 2012.

W.J. Zhang, Y.K. Kang and Y.M. Zhang, Real-Time Measurement of Weld Pool Surface in GTAW Process, Instrumentation and Measurement Conference (I2MTC), IEEE International, Minneapolis, MN, 2013, IEEE, p. 1640–1645, DOI: 10.1109/I2MTC.2013.6555692.

Y.M. Zhang, H.S. Song, and G. Saeed, Observation of a Dynamic Specular Weld Pool Surface, Meas. Sci. Technol., 2006, 17, p L9–L12. doi:10.1088/0957-0233/17/6/L02

S.G. Lambrakos, A. Shabaev and L. Huang, Inverse Thermal Analysis of a Titanium GTA Welds Using Multiple Constraint Conditions, J. Mater. Eng. Perform., 2015. DOI: 10.1007/s11665-015-1511-4

Acknowledgment

This work was supported by a Naval Research Laboratory (NRL) internal core program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lambrakos, S.G. Inverse Thermal Analysis of Welds Using Multiple Constraints and Relaxed Parameter Optimization. J. of Materi Eng and Perform 24, 2925–2936 (2015). https://doi.org/10.1007/s11665-015-1603-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1603-1