Abstract

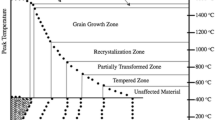

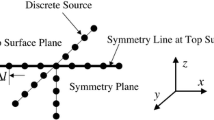

Inverse thermal analysis of titanium gas-tungsten-arc welds using multiple constraint conditions is presented. This analysis employs a methodology that is in terms of numerical-analytical basis functions for inverse thermal analysis of steady-state energy deposition in plate structures. The results of this type of analysis provide parametric representations of weld temperature histories that can be adopted as input data to various types of computational procedures, such as those for prediction of solid-state phase transformations. In addition, these temperature histories can be used to construct parametric function representations for inverse thermal analysis of welds corresponding to other process parameters or welding processes whose process conditions are within similar regimes. The present study applies an inverse thermal analysis procedure that provides for the inclusion of constraint conditions associated with both solidification and phase transformation boundaries.

Similar content being viewed by others

References

A.D. Zervaki, V. Stergiou, and S.G. Lambrakos, Case-Study Inverse Thermal Analysis of Al2139 and Al2198 Electron Beam Welds, J. Mater. Eng. Perform., 2013, 22(11), p 3175

S.G. Lambrakos, Inverse Thermal Analysis of Ti-6Al-4 V Deep-Penetration Welds Using Volumetric Constraints, J. Mater. Eng. Perform., 2014, 23(11), p 4019–4031

R.W. Farebrother, Linear Least Square Computations, Marcel Dekker, New York, 1988

Y.B. Bard, Nonlinear Parameter Estimation, Academic Press, New York, 1974

K. Levenberg, A Method for the Solution of Certain Non-linear Problems in Least-Squares, Quart. Appl. Math., 1944, 2, p 164–168

D.W. Marquardt, An Algorithm for Least Squares Estimation of Nonlinear Parameters, J. Soc. Ind. Appl. Moth, 1963, II, p 431–441

D.G. Duffy, Green’s Functions with Applications. Studies in Advanced Mathematics, 1st ed., Chapman and Hall/CRC, London, 2001

A.P. Mackwood and R.C. Crafer, Thermal Modeling of Laser Welding and Related Processes: A Literature Review, Opt. Laser Technol., 2005, 37(2), p 99–115

S. Kabra, D.W. Brown, C.-F. Chen, T.K. Wong, J.O. Milewski, “Measurement and Simulation of Residual Strain in A Laser Welded Titanium Ring,”. Proceeding of the 63rd IIW Conference, Istanbul, 2010

R. Rai, J.W. Elmer, T.A. Palmer, and T. DebRoy, Heat Transfer and Fluid Flow During Keyhole Mode Laser Welding of Tantalum, Ti-6AL-4 V, 304L Stainless Steel and Vanadium, J. Phys. D, 2007, 40, p 5753–5766

S. Mishra and T. DebRoy, Tailoring Gas Tungsten Arc Weld Geometry using a Genetic Algorithm and a Neural Network Trained with Convective Heat Flow Calculations, Mater. Sci. Eng. A, 2007, 454–455, p 477–486

A. Tarantola, Inverse Problem Theory and Methods for Model Parameter Estimation, SIAM, Philadelphia, 2005

M.N. Ozisik and H.R.B. Orlande, Inverse Heat Transfer, Fundamentals and Applications, Taylor and Francis, New York, 2000

K. Kurpisz and A.J. Nowak, Inverse Thermal Problems, Computational Mechanics Publications, Boston, 1995

O.M. Alifanov, Inverse Heat Transfer Problems, Springer, Berlin, 1994

J.V. Beck, B. Blackwell, and C.R. St, Clair, Inverse Heat Conduction: Ill-Posed Problems, Wiley Interscience, New York, 1985

J.V. Beck, “Inverse Problems in Heat Transfer with Application to Solidification and Welding,” Modeling of Casting, Welding and Advanced Solidification Processes V.M. Rappaz, M.R. Ozgu and K.W. Mahin Eds., The Minerals, Metals and Materials Society, Warrendale, 1991, p 427-437

J.V. Beck, “Inverse Problems in Heat Transfer,” Mathematics of Heat Transfer, G.E. Tupholme and A.S. Wood, Eds., Clarendon Press, Oxford, (1998), p. 13-24

S.G. Lambrakos and S.G. Michopoulos, Algorithms for Inverse Analysis of Heat Deposition Processes, ‘Mathematical Modelling of Weld Phenomena,’ Vol. 8, 847, Published by Verlag der Technischen Universite Graz, Austria (2007)

S.G. Lambrakos and J.O. Milewski, Analysis of Welding and Heat Deposition Processes using an Inverse-Problem Approach, Mathematical Modelling of Weld Phenomena, vol. 7, Publishied by Verlag der Technischen Universite Graz, Austria 2005, p 1025–1055

H.S. Carslaw and J.C. Jaegar, Conduction of Heat in Solids, 2nd ed., Clarendon Press, Oxford, 1959, p 374

S. Lathabai, K.J. Barton, L.K. Green, V.K. Tyagi, “Microstructure and Mechanical Properties of Keyhole Gas Tungsten Arc Welds in Titanium and Titanium Alloys,” Proceedings of the 7th International Conference on Trends in Welding Research, Pine Mountain, Georgia, 2005

J.W. Elmer, J. Wong, T. Ressler, J.W. Elmer, J. Wong, and T. Ressler, Spatially Resolved X-Ray Diffraction Phase Mapping and α → β → α Transformation Kinetics in the Heat-Affected Zone of Commercially Pure Titanium Arc Welds, Metall. Mater. Trans. A, 1998, 29A(11), p 2761–2773

S.V. Patankar, Numerical Heat Transfer and Fluid Flow, Series in Computational Methods in Mechanics and Thermal Sciences Hemisphere Publishing Corporation, London, 1980

V. Buljak, Inverse Analyses with Model Reduction, Computational Fluid and Solid Mechanics, Springer, Heidelberg 2012. doi:10.1007/978-3-642-22703-5_1

A. De and T. DebRoy, Reliable Calculations of Heat and Fluid Flow during Conduction Mode Laser Welding through Optimization of Uncertain Parameters, Weld. J., 2005, 84(7), p 101–112

A. Kumar and T. DebRoy, Reliable Modeling of Heat and Fluid Flow in Gas-Metal-Arc Fillet Welds through Optimization of Uncertain Variables, Trends in Welding Research: Proceedings of the 7th International Conference, Pine Mountain, GA, S.A. David, T. DebRoy, J. Lippold, H. Smartt, and J. Vitek, Eds., ASM International, Materials Park, OH, 2006, p 85–90.

A. Kumar and T. DebRoy, A Neural Network Model of Heat and Fluid Flow in Gas Metal Arc Fillet Welding based on Genetic Algorithm and Conjugate Gradient Optimization, Sci. Technol. Weld. Join., 2006, 11(1), p 106–119

Acknowledgment

This work was supported by a Naval Research Laboratory (NRL) internal core program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lambrakos, S.G., Shabaev, A. & Huang, L. Inverse Thermal Analysis of Titanium GTA Welds Using Multiple Constraints. J. of Materi Eng and Perform 24, 2401–2411 (2015). https://doi.org/10.1007/s11665-015-1511-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1511-4