Abstract

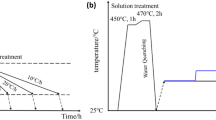

7xxx series Al-Zn-Mg-(Cu) alloys have higher strength in their peak-aged (T6) states compared with other age-hardenable aluminum alloys; however, the maximum strength peak-aged state is more susceptible to stress corrosion cracking (SCC) which leads to catastrophic failure. The over-aged (T7) temper with 10-15% lower strength has higher resistance to SCC requiring oversized structural aerospace component applications. The medium-strength AA7017 Al-Zn-Mg weldable alloy without Cu is also prone to SCC under certain environmental conditions. In the present investigation, the SCC behaviors of an AA7017 Al-Zn-Mg alloys of different tempers have been assessed. Specific aging schedules have been adapted to an AA7017 alloy to produce various tempers, e.g., under-, peak-(T6), over-(T7), and highly over-aged tempers. Artificial aging behavior of the AA7017 alloy has been characterized by hardness, electrical conductivity measurements, x-ray diffraction, differential scanning calorimetry, and electrochemical studies. Slow strain rate test technique was used to assess the SCC behaviors of the AA7017 alloys of under-, T6, T7, and highly over-aged tempers in 3.5 wt.% NaCl solution at free corrosion potential (FCP) and at applied anodic potential, as well. Results revealed that the AA7017 alloy tempers are not susceptible to SCC in 3.5 wt.% NaCl solution at FCP, but severely damaging to SCC at applied anodic potentials. Microstructural features, showing a non-recrystallized grain structure and the presence of discrete, widely spaced, not-interconnected η precipitates at the grain boundaries, are the contributive factors by virtue of which the alloy tempers at FCP did not exhibit SCC. However, the applied anodic potential resulted in rapid metal dissolution from the grain boundary region and led to SCC. The local anodic dissolution (LAD) is believed to be the associated SCC mechanism.

Similar content being viewed by others

References

Z. Huda and P. Edi, Materials Selection in Design of Structures and Engines of Supersonic Aircrafts: A Review, Mater. Des., 2013, 46(April), p 552–560

E.A. Starke, Jr., and J.T. Staley, Application of Modern Aluminium Alloys to Aircraft, Prog. Aerosp. Sci., 1996, 32(2–3), p 131–172

J.C. Williams and E.A. Starke, Jr., Progress in Structural Materials for Aerospace Systems, Acta Mater., 2003, 51(19), p 5775–5799

I.J. Polmear, Light Alloys-Metallurgy of the Light Metals, 2nd ed., Edward Arnold, London, 1989, p 18–143

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, and R. Benedictus, Recent Development in Aluminium Alloys for Aerospace Applications, Mater. Sci. Eng. A, 2000, 280(1), p 102–107

J.C. Werenkiold, A. Deschamps, and Y. Brechet, Characterization and Modeling of Precipitation Kinetics in an Al-Zn-Mg Alloy, Mater. Sci. Eng. A, 2000, 293(1–2), p 267–274

K. Stiller, P.J. Warren, V. Hansen, J. Angenete, and J. Gjønnes, Investigation of Precipitation in an Al-Zn-Mg Alloy After Two-Step Ageing Treatment at 100° and 150°C, Mater. Sci. Eng. A, 1999, 270(1), p 55–63

J. Buha, R.N. Lumley, and A.G. Crosky, Secondary Ageing in an Aluminum Alloy 7050, Mater. Sci. Eng. A, 2008, 492(1–2), p 1–10

M.O. Speidel, Stress Corrosion Cracking of Aluminium Alloys, Metall. Trans. A, 1975, 6(4), p 631–651

H. Fooladfar, B. Hashemi, and M. Younesi, The Effect of the Surface Treating and High Temperature Ageing on the Strength and SCC Susceptibility of 7075 Aluminium Alloy, J. Mater. Eng. Perform., 2010, 19(6), p 852–859

B. Cina, Reducing the Susceptibility of Alloys Particularly Aluminium Alloys to Stress Corrosion Cracking, US Patent, 3856584, 24 Dec 1974

L.P. Huang, K.H. Chen, and S. Li, Influence of Grain-Boundary Pre-precipitation and Corrosion Characteristics of Inter-granular Phases on Corrosion Behaviours of an Al-Zn-Mg-Cu Alloy, Mater. Sci. Eng. B, 2012, 177(11), p 862–868

D. Najjar, T. Magnin, and T.J. Warne, Influence of Critical Surface Defects and Localized Competition Between Anodic Dissolution and Hydrogen Effects During Stress Corrosion Cracking of a 7050 aluminium alloy, Mater. Sci. Eng. A, 1997, 238(2), p 293–302

R.G. Song, W. Dietzel, B.J. Zhang, W.J. Liu, M.K. Tseng, and A. Atrens, Stress Corrosion Cracking and Hydrogen Embrittlement of an Al-Zn-Mg-(Cu) Alloy, Acta Mater., 2004, 52(4), p 4727–4743

M.B. Kanan, V.S. Raja, R. Raman, and A.K. Mukhopadhay, Influence of Multistep Ageing on Stress Corrosion Cracking Behaviour of Aluminium Alloy, Corrosion, 2003, 59(10), p 881–889

R.K. Viswanadham, T.S. Sun, and J.A.S. Green, Grain Boundary Segregation in Al-Zn-Mg Alloys—Implications to Stress Corrosion Cracking, Metall. Trans. A, 1980, 11(1), p 85–89

J. Albrecht, I.M. Bernstein, and A.W. Thompson, Thermotransport of Hydrogen and Deuterium in Vanadium, Niobium, and Tantalum, Metall. Trans. A, 1982, 13, p 811–820

L.M. Wu, W.H. Wang, Y.F. Hsu, and S. Trong, Effects of Microstructure on the Mechanical Properties and Stress Corrosion Cracking of an Al-Zn-Mg-Sc-Zr Alloy by Various Temper Treatments, Mater. Trans, 2007, 48(3), p 600–609

N.H. Holroyd and G.M. Scamans, Stress Corrosion Cracking in Al-Zn-Mg-Cu Aluminium Alloys in Saline Environments, Metall. Mater. Trans. A, 2013, 44(March), p 1230–1253

W. Gruhl, Stress Corrosion Cracking of High Strength Aluminium Alloys, Z. Metallkd., 1984, 75, p 819–826

M.B. Kannan and V.S. Raja, Enhancing Stress Corrosion Cracking Resistance in Al-Zn-Mg-Cu-Zr alloy through inhibiting recrystalization, Eng. Fract. Mech., 2010, 77(2), p 249–256

Y. Deng, Z. Yin, K. Zhao, J. Duan, J. Hu, and Z. He, Effects of Sc and Zr Microalloying Additions and Ageing Time at 120°C on the Corrosion Behaviour of an Al-Zn-Mg Alloy, Corros. Sci., 2012, 65(December), p 288–299

P.K. Rout, M.M. Ghosh, and K.S. Ghosh, Effect of Solution pH on Electrochemical and Stress Corrosion Cracking Behaviour of a 7150 Al-Zn-Mg-Cu Alloy, Mater. Sci. Eng. A, 2014, 604(May), p 156–165

M. Czechowski, Effect of Anodic Polarization on Stress Corrosion Cracking of Some Aluminium Alloy, Adv. Mater. Sci., 2007, 7(1), p 13–20

A.E. Patterson, Introduction to Aluminium, Aluminium Federation of South Africa, Gauteng, 2007

K.S. Kumar, D. Singh, and T.B. Bhat, Studies on Aluminum Armour Plates Impacted by Deformable and Non-deformable Projectiles, Mater. Sci. Forum, 2004, 465–466, p 79–84

C.G. Cordovilla, E. Louis, A. Pamies, L. Caballero, and M. Elices, Microstructure and Susceptibility to Stress Corrosion Cracking of Al-Zn-Mg Weldments (AA-7017), Mater. Sci. Eng. A, 1994, 174(2), p 173–186

K.S.S. Eswar Raju, A.K. Mukhopadhayay, and S.V. Kamat, The Effect of Ageing on Tensile Behaviour, Mode I, and Mixed Mode I/III, Fracture Toughness of 7010 Aluminium Alloy, Int. J. Mater. Res., 2006, 97(11), p 1550–1558

A.K. Mukhopadhyay, K.S. Prasad, V. Kumar, G.M. Reddy, S.V. Kamat, and V.K. Varma, Key Microstructural Features Responsible for Improved Stress Corrosion Cracking Resistance and Weldability in 7xxx Series Al Alloys Containing Micro/Trace Alloying Additions, Mater. Sci. Forum, 2006, 519–521, p 315–320

C.G. Cordovilla, E. Louis, A. Pamies, L. Caballero, V. Sanchez-Galvez, and M. Elices, Stress Corrosion Susceptibility of Al-Zn-Mg Weldments: Microstructural Effects, Scr. Metall., 1989, 23(12), p 2091–2096

J.C.F. Millette, N.K. Bourne, and M.R. Edwards, The Effect of Heat Treatment on the Shock Induced Mechanical Properties of the 7017 Aluminium Alloy, Scr. Mater., 2004, 51(10), p 967–971

H. Möller and G. Govender, The Heat Treatment of Rheo-High Pressure Die Cast Al-Zn-Mg Alloy 7017, Solid State Phenom., 2013, 192–193, p 155–160J

Y. He, X. Zhang, and J. You, Effect of Minor Sc and Zr on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy, Trans. Nonferrous Met. Soc. China, 2006, 16(5), p 1228–1235

Z. Li, B. Xiong, Y. Zhang, B. Zhu, F. Wang, and H. Liu, Ageing Behaviour of an Al-Zn-Mg-Cu Alloy Pre-stretched Thick Plate, Material, 2007, 14(3), p 246–250

R.H. Brown and L.A. Willey, Constitution of Alloy, Aluminium, Vol 1, K.R. Van-Horn, Ed., ASM, Metal Park, 1967, p 31–54

A.K. Mukhopadhyay, C.N.J. Tite, H.M. Flower, P.J. Gregson, and F. Sale, Aluminium Lithium Alloys IV, Proceedings of the 4th International Conference on Aluminium Lithium Alloys, G. Champier, B. Dubost, D. Miannay and L. Sabetay, Paris, Ed., June, 1987 (Journal de Phyique, Suppl. 48), p C3:439.

J.T. Jiang, W.Q. Xiao, L. Yang, W.Z. Shao, S.J. Yuan, and L. Zhen, Ageing Behaviour and Stress Corrosion Cracking Resistance of a Non-isothermally Aged Al-Zn-Ng-Cu Alloy, Mater. Sci. Eng. A, 2014, 605, p 167–175

X. Fang, Y. Du, C. Jiang, M. Song, and K. Li, Effects of Cu Content on the Precipitation Process of Al-Zn-Mg Alloys, J. Mater. Sci., 2012, 47(23), p 8174–8187

N. Birbilis and R.G. Buchheit, Investigation and Discussion of Characteristics for Intermetallic Phases Common to Aluminium Alloys as a Function of Solution pH, J. Electrochem. Soc., 2008, 155(3), p 117–126

Y.L. Wua, U.F.H. Froesa, A. Alvareza, C.G. Lib, and J. Liuc, Microstructure and Properties of a New Super-High-Strength Al-Zn-Mg-Cu Alloy, C912, Mater. Des., 1997, 18(4–6), p 211–215

H.C. Fang, K.H. Chen, X. Chen, H. Chao, and G.S. Peng, Effect of Cr, Yb and Zr Additions on Localized Corrosion of Al-Zn-Mg-Cu Alloy, Corros. Sci., 2009, 51(12), p 2872–2877

S. Chen, K. Chen, P. Dong, S. Ye, and L. Huang, Effect of Recrystallization and Heat Treatment on Strength and SCC of an Al-Zn-Mg-Cu Alloy, J. Alloys Compd., 2013, 581(December), p 705–709

G.S. Peng, K.H. Chen, H.C. Feng, Y.S. Chen, and H. Chao, The Effect of Recrystallization on Corrosion and Electrochemical Behaviour of 7150 Al Alloy, Mater. Corros., 2011, 62(1), p 35–40

A.K. Jha, P.R. Narayanan, K. Sreekumar, and P.P. Sinha, Cracking of Al-4.5Zn-1.5Mg Aluminium Alloy Propellant Tank—A Metallurgical Investigation, Eng. Fail. Anal., 2010, 17(2), p 562–570

R.H. Jones, ASM Handbook 13A. Corrosion: Fundamentals, Testing, and Protections, Metal Park, ASM, 2003, p 349–350

Acknowledgments

The authors are very much thankful to the technical staff members of the Central Research Facility (CRF), and the IIT Kharagpur, India for allowing them to avail the facilities of SEM, TEM, and the hot and cold rolling mills as well.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rout, P.K., Ghosh, M.M. & Ghosh, K.S. Influence of Aging Treatments on Alterations of Microstructural Features and Stress Corrosion Cracking Behavior of an Al-Zn-Mg Alloy. J. of Materi Eng and Perform 24, 2792–2805 (2015). https://doi.org/10.1007/s11665-015-1559-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1559-1