Abstract

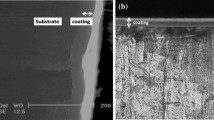

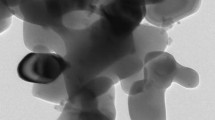

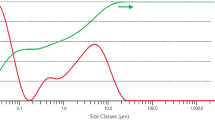

In this study, step-wise multilayer and functionally graded Ni-P coatings were deposited with electroless in which the content of phosphorus and nickel would be changed gradually and step-wise through the thickness of the coatings, respectively. To compare the properties of these coatings with Ni-P single-layer coatings, three types of coatings with different phosphorus contents were deposited. Heat treatment of coatings was performed at 400 °C for 1 h. The microstructure and phase transformation of coatings were characterized by SEM/EDS, TEM, and XRD. The mechanical properties of coatings were studied by nanoindentation test. According to the results of the single-layer coatings, low P coating had the maximum hardness and also the ratio of hardness (H) to elasticity modulus (E) for the mentioned coating was maximum. In addition, low and medium P coatings had crystalline and semi-crystalline structure, respectively. The mentioned coatings had 〈111〉 texture and after heat treatment their texture didn’t change. While high P coating had amorphous structure, after heat treatment it changed to crystalline structure with 〈100〉 texture for nickel grains. Furthermore, the results showed that functionally graded and step-wise multilayer coatings were deposited successfully by using the same initial bath and changing the temperature and pH during deposition. Nanoindentation test results showed that the hardness of the mentioned coatings changed from 670 Hv near the substrate to 860 Hv near the top surface of coatings. For functionally graded coating the hardness profile had gradual changes, while step-wise multilayer coating had step-wise hardness profile. After heat treatment trend of hardness profiles was changed, so that near the substrate, hardness was measured 1400 Hv and changed to 1090 Hv at the top coat.

Similar content being viewed by others

References

H.W. Ni, H.S. Zhang, R.S. Chen, W.T. Zhan, K.F. Huo, and Z.Y. Zuo, Antibacterial Properties and Corrosion Resistance of AISI, 420 Stainless Steels Implanted by Silver and Copper Ions, Int. J. Miner. Metall. Mater., 2012, 19(4), p 322–327 (in English)

R. Liu, Y. Qiao, M. Yan, and Y. Fu, Mechanical and Corrosion Resistant Properties of Martensitic Stainless Steel Plasma Nitrocarburized with rare Earths Addition, J. Rare Earths, 2012, 30(8), p 826–830 (in English)

S. Armyanov, T. Vangelova, and R. Stoyanchev, Pretreatment of Al-Mg Alloys for Electrodeposition by Immersion Zinc and Electroless Nickel, Surf. Technol., 1982, 17(2), p 89–100 (in English)

J. Sudagar, K. Venkateswarlu, and J. Lian, Dry Sliding Wear Properties of a 7075-T6 Aluminum Alloy Coated with Ni-P (h) in Different Pretreatment Conditions, J. Mater. Eng. Perform., 2010, 19(6), p 810–818 (in English)

P. Peeters, G.V.D. Hoorn, T. Daenen, A. Kurowski, and G. Staikov, Properties of Electroless and Electroplated Ni-P and its Application in Microgalvanics, Electrochim. Acta, 2001, 47, p 161–169 (in English)

B. Jiang, S.L. Jiang, A.L. Ma, and Y.G. Zheng, Erosion-Corrosion Behavior of Electroless Ni-P Coating on Copper-Nickel Alloy in 3.5 wt.% Sodium Chloride Solution, J. Mater. Eng. Perform., 2014, 23, p 230–237 (in English)

S. Park and D. Lee, A Study on the Microstructure and Phase Transformation of Electroless Nickel Deposits, J. Mater. Sci., 1988, 23(5), p 1643–1654 (in English)

A.W. Goldstein, W. Rostoker, and J.J. Rezek, Electron Microscope Study of the Nucleation and Growth of Electroless Cobalt and Nickel, Electrochem. Soc., 1972, 119(12), p 1614–1619 (in English)

E. Vafaei-Makhsoos, E.L. Thomas, and L.E. Toth, Electron Microscopy of Crystalline and Amorphous Ni-P Electrodeposited Films: In Situ Crystallization of an Amorphous Solid, Metall. Trans., 1978, 9, p 1449–1460 (in English)

R. Taheri, “Evaluation of Electroless Nickel-Phosphorus (EN) Coatings”, Ph.D. Thesis, Saskatchewan University, 2002.

G.G. Gawrilw, Chemical (Electroless) Nickel-Plating, Protcullis press Ltd., Redhill, UK, 1979, p 101

W. Riedel, Electroless Nickel Plating, ASM International, Metals Parks, 1991, p 68–69

D.N. Lee and K.H. Hur, The Evolution of Texture During Annealing of Electroless Ni-Co-P Deposits, Scr. Mater., 1999, 40(12), p 1333–1339 (in English)

T.S.N. Sankara Narayanan, I. Baskaran, K. Krishnaveni, and S. Parthiban, Deposition of Electroless Ni-P Graded Coatings and Evaluation of their Corrosion Resistance, Surf. Coat. Technol., 2006, 200(11), p 3438–3445 (in English)

I. Ayoub, Study of Electroless Ni-P Plating on Stainless Steel, Online J. Math. Stat., 2009, 1, p 13–16 (in English)

T. Ungár, Dislocation Densities, Arrangements and Character from x-ray Diffraction Experiments, Mater. Sci. Eng. A, 2001, 309-310, p 14–22 (in English)

G.K. Williamson and W.H. Hall, X-ray Line Broadening from Field Aluminium and Wolfram, Acta Metall., 1953, 1, p 22–31 (in English)

P. SampathKumar and P. Kesavan, Nair, Studies on Crystallization of Electroless Ni-P Deposits, J. Mater. Process. Technol., 1996, 56, p 511–520 (in English)

I. Apachitei, F.D. Tichelaar, J. Duszczyk, and L. Katgerman, The Effect of Heat Treatment on the Structure and Abrasive Wear Resistance of Autocatalytic NiP and NiP-SiC Coatings, Surf. Coat. Technol., 2002, 149(2), p 263–278 (in English)

R. Carel, C.V. Thompson, and H.J. Frost, Computer Simulation of Strain Energy Effects Versus Surface and Interface Energy Effects on Grain Growth in Thin Films, Acta Mater., 1996, 44(6), p 2479–2494 (in English)

A. Leyland and A. Matthews, On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour, J. Wear, 2000, 246, p 1–11 (in English)

A. Matthews, and A. Leyland, Materials Related Aspects of Nanostructured Tribological Coatings, in Proceedings of 51st Annual Technical Conference, 2008, Society of Vacuum Coaters, Albuquerque, 2009, p 744.

M.F. Yan and R.L. Liu, Martensitic Stainless Steel Modified by Plasma Nitrocarburizing at Conventional Temperature with and Without Rare Earths Addition, Surf. Coat. Technol., 2010, 205(2), p 345–349 (in English)

Acknowledgment

The authors would like to thank Dr. Mohsen Abbasi for his helpful assistance in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anvari, S.R., Monirvaghefi, S.M. & Enayati, M.H. Novel Investigation on Nanostructured Multilayer and Functionally Graded Ni-P Electroless Coatings on Stainless Steel. J. of Materi Eng and Perform 24, 2373–2381 (2015). https://doi.org/10.1007/s11665-015-1533-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1533-y