Abstract

In the present study, the reliance of deformation mechanism of a super-austenitic steel (Sanicro-28) on the external stress and stacking fault energy (SFE) was quantitatively investigated by analyzing the stacking fault separation. The stacking fault energy of the experimental alloy was determined using line profile analysis through x-ray diffraction measurements. Considering the calculated SFE and external stress, the predominant deformation mechanism was predicted by a quantitative model. A set of experimental examinations were carried out validating the applied model. The experimental findings reveal that the plasticity mechanism of steel can be divided into two stages. In the first stage (at lower strain), no mechanical twin was observed in the microstructure and the dislocation glide would control the plasticity. In the second stage (at higher strain), the mechanical twinning was considered as the predominant plasticity mechanism. Furthermore, regarding the stress threshold of mechanical twin formation, as the SFE increases, the critical stress for mechanical twinning initiation intensifies. However, in the present super-austenitic stainless steel, the mechanical twinning was observed at the stresses lower than those predicted by the applied model. This was related to the various interactions between dislocation and different barriers in the solid solution matrix.

Similar content being viewed by others

References

J. Unfried-Silgado, L. Wu, F. Furlan-Ferreira, C. Mario-Garzon, and A.J. Ramirez, Stacking Fault Energy Measurements in Solid Solution Strengthened Ni-Cr-Fe Alloys Using Synchrotron Radiation, Mater. Sci. Eng. A, 2012, 558, p 70–75

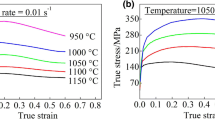

A. Mirzaei, A. Zarei-Hanzaki, N. Haghdadi, and A. Marandi, Constitutive Description of High Temperature Flow Behavior of Sanicro-28 Super-Austenitic Stainless Steel, Mater. Sci. Eng. A, 2014, 589, p 76–82

P. Behjati and A. Najafizadeh, Role of Chemical Driving Force in Martensitic Transformations of High-Purity Fe-Cr-Ni Alloys, Metall. Mater. Trans. A, 2011, 42, p 3752–3760

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton, Correlations Between the Calculated Stacking Fault Energy and the Plasticity Mechanisms in Fe-Mn-C Alloys, Mater. Sci. Eng. A, 2004, 387, p 158–162

P. Seemann, S. Kurz, and P. Gümpel, Martensite Formation in a New Manganese Alloyed Metastable Austenitic Steel (AISI, 200-Series), J. Alloy. Compd., 2013, 577, p 649–653

X. Peng, D. Zhu, Z. Hu, W. Yi, H. Liu, and M. Wang, Stacking Fault Energy and Tensile Deformation Behavior of High-Carbon Twinning-Induced Plasticity Steels: Effect of Cu Addition, Mater. Des., 2013, 45, p 518–523

S. Curtze, V.T. Kuokkala, A. Oikari, J. Talonen, and H. Hänninen, Thermodynamic Modeling of the Stacking Fault Energy of Austenitic Steels, Acta. Mater., 2011, 59, p 1068–1076

L. Brown and A. Thölén, Shape of Three-Fold Extended Nodes, Discuss. Faraday. Soc., 1964, 38, p 35–41

A. Ruff, Measurement of Stacking Fault Energy from Dislocation Interactions, Metal. Trans., 1970, 1, p 2391–2413

A. Howie and P. Swann, Direct Measurements of Stacking-Fault Energies from Observations of Dislocation Nodes, Philos. Mag., 1961, 6, p 1215–1226

R. Schramm and R. Reed, Stacking Fault Energies of Seven Commercial Austenitic Stainless Steels, Metal. Trans. A, 1975, 6, p 1345–1351

J. Talonen and H. Hänninen, Formation of Shear Bands and Strain-Induced Martensite During Plastic Deformation of Metastable Austenitic Stainless Steels, Acta. Mater, 2007, 55, p 6108–6118

X. Tian and Y. Zhang, Effect of Si Content on the Stacking Fault Energy in γ-Fe-Mn-Si-C alloys: Part I. X-ray Diffraction Line Profile Analysis, Mater. Sci. Eng. A, 2009, 516, p 73–77

J.E. Jin and Y.K. Lee, Effects of Al on Microstructure and Tensile Properties of C-Bearing High Mn TWIP Steel, Acta. Mater., 2012, 60, p 1680–1688

B.E. Warren, X-Ray Diffraction, Addison-Wesley, Massachusett, 1969

T. Byun, On the Stress Dependence of Partial Dislocation Separation and Deformation Microstructure in Austenitic Stainless Steels, Acta. Mater., 2003, 51, p 3063–3071

K.-T. Park, K.G. Jin, S.H. Han, S.W. Hwang, K. Choi, and C.S. Lee, Stacking fault energy and Plastic Deformation of Fully Austenitic High Manganese Steels: Effect of Al Addition, Mater. Sci. Eng. A, 2010, 527, p 3651–3661

G. Williamson and W. Hall, X-Ray Line Broadening from Filed Aluminium and Wolfram, Acta. Metall., 1953, 1, p 22–31

ASTM E209, Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures With Conventional or Rapid Heating Rates and Strain Rates. Annual Book of ASTM Standards, ASTM International, PA, 2010.

P. Brofman and G. Ansell, On the Effect of Carbon on the Stacking Fault Energy of Austenitic Stainless Steels, Metal. Mater. Trans A, 1978, 9, p 879–880

C.G. Rhodes and A.W. Thompson, The Composition Dependence of Stacking Fault Energy in Austenitic Stainless Steels, Metal. Trans. A, 1977, 8, p 1901–1906

S. Allain, J.-P. Chateau, and O. Bouaziz, A Physical Model of the Twinning-Induced Plasticity Effect in a High Manganese Austenitic Steel, Mater. Sci. Eng. A, 2004, 387, p 143–147

S. Curtze and V.-T. Kuokkala, Dependence of Tensile Deformation Behavior of TWIP Steels on Stacking Fault Energy, Temperature and Strain Rate, Acta. Mater., 2010, 58, p 5129–5141

E. Lee, T. Byun, J. Hunn, M. Yoo, K. Farrell, and L. Mansur, On the Origin of Deformation Microstructures in Austenitic Stainless Steel: Part I—Microstructures, Acta. Mater, 2001, 49, p 3269–3276

E. Lee, M. Yoo, T. Byun, J. Hunn, K. Farrell, and L. Mansur, On the Origin of Deformation Microstructures in Austenitic Stainless Steel: Part II—Mechanisms, Acta. Mater, 2001, 49, p 3277–3287

E. Lee, T. Byun, J. Hunn, K. Farrell, and L. Mansur, Origin of Hardening and Deformation Mechanisms in Irradiated 316 LN Austenitic Stainless Steel, J. Nucl. Mater., 2001, 296, p 183–191

F. Lecroisey and A. Pineau, Martensitic Transformations Induced by Plastic Deformation in the Fe-Ni-Cr-C System, Metal. Trans., 1972, 3, p 391–400

F.A. Mohamed, Incorporation of the Suzuki and the Fisher Interactions in the Analysis of Creep Behavior of Solid Solution Alloys, Mater. Sci. Eng., 1983, 61, p 149–165

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moallemi, M., Zarei-Hanzaki, A. & Mirzaei, A. On the Stacking Fault Energy Evaluation and Deformation Mechanism of Sanicro-28 Super-Austenitic Stainless Steel. J. of Materi Eng and Perform 24, 2335–2340 (2015). https://doi.org/10.1007/s11665-015-1501-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1501-6