Abstract

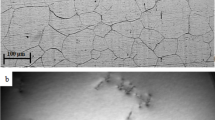

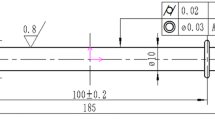

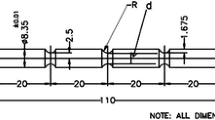

Creep rupture properties of austenitic stainless steel foil, 347SS, used in compact recuperators have been evaluated at 700 °C in the stress range of 54-221 MPa to establish the baseline behavior for its extended use. Creep curves of the foil show that the primary creep stage is brief and creep life is dominated by tertiary creep deformation with rupture lives in the range of 10-2000 h. Results are compared with properties of bulk specimens tested at 98 and 162 MPa. Thin foil 347SS specimens were found to have higher creep rates and higher rupture ductility than their bulk specimen counterparts. Power law relationship was obtained between the minimum creep rate and the applied stress with stress exponent value, n = 5.7. The value of the stress exponent is indicative of the rate-controlling deformation mechanism associated with dislocation creep. Nucleation of voids mainly occurred at second-phase particles (chromium-rich M23C6 carbides) that are present in the metal matrix by decohesion of the particle-matrix interface. The improvement in strength is attributed to the precipitation of fine niobium carbides in the matrix that act as obstacles to the movement of dislocations.

Similar content being viewed by others

References

R.K. Shah and D.R. Sekulib, Heat Exchangers, Handbook of Heat Transfer, chapter 17, W.M. Rohsenow, J.P. Hartnett, and Y.I. Cho, Ed., University of Kentucky, New York, 1998,

C.F. McDonald, Recuperator Considerations for Future Higher Efficiency Microturbines, Appl. Therm. Eng., 2003, 23, p 1463–1487

P.J. Maziasz, R.W. Swindeman, J.P. Shingledecker, K.L. More, B.A. Pint, E. Lara-Curzio, and N.D. Evans, Improving High-Temperature Performance of Austenitic Stainless Steels for Advanced Microturbine Recuperators, Engineering Issues in Turbine Machinery, Power Plants and Renewables, The Institute for Materials, Minerals and Mining, Maney Publishing, London, 2003, p 1057–1073

P.J. Ennis, Candidate Materials for a Modular High Temperature Reactor Power Plant, Engineering Issues in Turbine Machinery, Power Plants and Renewables, The Institute of Materials, Minerals and Mining, Maney Publishing, London, 2003, p 1029–1037.

P.J. Maziasz and R.W. Swindeman, Selecting and Developing Advanced Alloys for Creep Resistance for Microturbine Recuperator Applications, J. Eng. Gas Turbines Power, 2003, 125, p 51–58

P.J. Maziasz, B.A. Pint, J.P. Shingledecker, K.L. More, D.E. Evans, and E. Lara-Curzio, Austenitic Stainless Steels and Alloys with Improved High-Temperature Performance for Advanced Microturbine Recuperators, ASME, 2004, 6, p 131–143

O.O. Omatete, P.J. Maziasz, B.A. Pint, and D.P. Stinton, Assessment of Recuperator Materials for Microturbines, ORNL/TM-2000-304, 2000

T. Kawasaki and M.H. Chi, Analysis of Accelerated Creep under Constant Sustaining Load for Austenitic Stainless Steels, Metall. Trans. A, 1979, 10A, p 749

K. Laha, J. Kyono, and N. Shinya, Copper, Boron, and Cerium Additions in Type 347 Austenitic Steel to Improve Creep Rupture Strength, Metall. Mater. Trans. A, 2012, 43A, p 1187

A. Nassour, W.W. Bose, and D. Spinelli, Creep Properties of Austenitic Stainless-Steel Weld Metals, JMEPEG, 2001, 10(6), p 693–698

Y. Minami, H. Kimura, and Y. Ihara, Microstructural Changes in Austenitic Stainless Steels During Long-Term Aging, Mater. Sci. Tech., 1986, 2, p 795–806

T. Sourmail, Precipitation in Creep-Resistant Austenitic Stainless Steels, Mater. Sci. Technol, 2001, 17, p 1–14

K. Laha, J. Kyono, T. Sasaki, S. Kishimoto, and N. Shinya, Improved Creep Strength and Creep Ductility of Type 347 Austenitic Stainless Steel through the Self-Healing Effect of Boron for Creep Cavitation, Metall. Mater. Trans. A, 2005, 36A, p 399–409

N. Shinya, J. Kyono, and K. Laha, Self-Healing Effect of Boron Nitride Precipitation on Creep Cavitation in Austenitic Stainless Steels, J. Intell. Mater. Syst. Struct., 2006, 17, p 1127–1133

N. Shinya, J. Kyono, and K. Laha, An Advanced Creep Cavitation Resistance in Cu-containing 18Cr-12Ni-Nb Austenitic Stainless Steels, Scripta Mater., 2007, 56, p 915–918

K. Laha, J. Kyono, and N. Shinya, Some Chemical and Microstructural Factors Influencing Creep Cavitation Resistance of Austenitic Stainless Steels, Philos. Mag. A, 2007, 87(17), p 2483–2505

S.H. Avner, Introduction to Physical Metallurgy, McGraw-Hill International, New York, 1974

Standard Test Methods for Conducting Creep, Creep-Rupture and Stress Rupture Tests of Metallic Materials, E139, Annual Book of ASTM Standards, 2000

M.D. Mathew, S. Latha, S.L. Mannan, and P. Rodriguez, Creep Rupture Properties of Solution Annealed and Cold Worked Type 316 Stainless Steel Cladding Tubes, Report IGC-117, 1990

R.W. Evans and B. Wilshire, Introduction to Creep, The Institute of Materials, London, 1993, p 62

D.G. Morris and D.R. Harries, Creep and Rupture in Type 316 Stainless Steel at Temperatures between 525 and 900°C Part I: Creep Rate, Metal Sci., 1978, 12, p 525–531

S.L. Mannan and P. Rodriguez, Effect of Grain Size on Creep Rate in Type 316 Stainless Steel at 873 and 973 K, Metal Sci., 1983, 17, p 63–69

M.D. Mathew, G. Sasikala, K.B.S. Rao, and S.L. Mannan, Influence of Carbon and Nitrogen on the Creep Properties of Type 316 Stainless Steel at 873 K, Mater. Sci. Eng., 1991, A148, p 253–260

H.J. Frost and M.F. Ashby, Deformation Mechanism Maps, Pergamon Press, Oxford, 1982

W. Kesternich and D. Meertens, Microstructural Evolution of a Titanium Stabilized 15Cr-15Ni Steel, Acta Metall., 1986, 34(6), p 1071–1082

L.M. Brown and J.D. Embury, The Initiation and Growth of Voids at Second-Phase Particles, Proceedings of the 3rd International Conference on Strength of Metals and Alloys, Institute of Metals, London, 1973, p 164–169.

K.E. Puttick, Ductile Fracture in Metals, Philos. Mag. Ser., 1959, 84(44), p 964–969

A.S. Argon and J. Im, Separation of Second Phase Particles in Spheroidized 1045 Steel, Cu-0.6%Cr Alloy, and Maraging Steel in Plastic Straining, Metall. Trans. A, 1975, 6, p 839–851

H.O. Ali and M.N. Tamin, Modified Monkman-Grant Relationship for Austenitic Stainless Steel Foils, J. Nucl. Mater., 2013, 433, p 74–79

C.K. Lin and I.L. Lan, Fatigue Behavior of AISI, 347 Stainless Steel in Various Environments, J. Mater. Sci., 2004, 39(23), p 6901–6908

Acknowledgment

This study is funded by the Ministry of Higher Education Malaysia (MOHE) through Research Grant No. 4F154

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Osman, H., Borhana, A. & Tamin, M.N. Material Parameters for Creep Rupture of Austenitic Stainless Steel Foils. J. of Materi Eng and Perform 23, 2858–2863 (2014). https://doi.org/10.1007/s11665-014-1070-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1070-0