Abstract

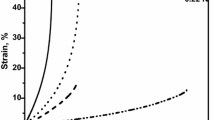

Creep deformation and rupture behavior of nitrogen-alloyed (0.14 wt.%) nuclear grade 316LN austenitic stainless steel were investigated for the varying stress levels at 873 K and 923 K. The power-law dependency of creep properties such as steady-state creep rate and rupture life on applied stress was observed. For a given applied stress condition, a systematic increase in strain to failure was noticed with increasing temperature from 873 K to 923 K. Irrespective of test temperatures, creep rupture elongation of the steel increased with the increase in rupture lifetime (\(t_{r}\)) for \(t_{r} > 1000\) h. Analysis indicated that the interdependency between creep properties could be well described by the modified Monkman-Grant relationship. The predominance of inter-granular fracture arising from the triple point cracks and/or coalescence of cavities was observed at all the tested conditions for the steel. The enhanced tendency for wedge cracking was noticed for high stress levels at 873 K and 923 K. The evaluated damage tolerance factor \((\lambda ) < 5\) and the calculated ratio between time to reach the Monkman-Grant strain and creep rupture lifetime in the range of 0.69 to 0.80 indicated the accumulation of Monkman-Grant strain for the major fraction of lifetime during creep deformation of 316LN steel.

Similar content being viewed by others

Data Availability

The data required to reproduce these findings cannot be shared at this time due to technical and legal reasons.

References

Alomari, A.S., Kumar, N., Murty, K.L.: Creep behavior and microstructural evolution of a Fe-20Cr-25Ni (mass percent) austenitic stainless steel (alloy 709) at elevated temperatures. Metall. Mater. Trans. A 50(2), 641–654 (2019)

Ashby, M.F., Dyson, B.F.: Creep damage mechanics and micromechanisms. In: Fracture, vol. 84, pp. 3–30. Pergamon, Elmsford (1984)

Byrnes, M.L.G., Grujicic, M., Owen, W.S.: Nitrogen strengthening of a stable austenitic stainless steel. Acta Metall. 35(7), 1853–1862 (1987)

Choudhary, B.K.: Tertiary creep behaviour of 9Cr–1Mo ferritic steel. Mater. Sci. Eng. A 585, 1–9 (2013)

Choudhary, B.K., Samuel, E.I., Christopher, J., Yadav, S.D.: Comparative evaluation of creep-rupture behavior of P9 steel plate and thick section tubeplate forging. J. Mater. Eng. Perform. 28(10), 6307–6319 (2019)

Christopher, J., Choudhary, B.K.: Constitutive description of primary and steady-state creep deformation behaviour of tempered martensitic 9Cr–1Mo steel. Philos. Mag. 96, 2256–2279 (2016)

Dobeš, F., Milička, K.: The relation between minimum creep rate and time to fracture. Met. Sci. 10(11), 382–384 (1976)

Frost, H.J., Ashby, M.F.: Deformation Mechanism Maps: The Plasticity and Creep of Metals and Ceramics. Pergamon, Elmsford (1982)

Ganesan, V., Mathew, M.D., Sankara Rao, K.B.: Influence of nitrogen on tensile properties of 316LN SS. Mater. Sci. Technol. 25(5), 614–618 (2009)

Horsewell, A.: Creep inhibition at grain boundaries in a stainless steel. Metall. Trans. A 9, 1843–1847 (1978)

Kachanov, L.M.: In: The Theory of Creep. Wetherby, Boston (1960)

Kim, W.G., Park, J.Y., Ekaputra, I.M., Kim, S.J., Kim, M.H., Kim, Y.W.: Creep deformation and rupture behavior of Alloy 617. Eng. Fail. Anal. 58, 441–451 (2015)

Lai, J.K., Wickens, A.: Microstructural changes and variations in creep ductility of 3 casts of type 316 stainless steel. Acta Metall. 27(2), 217–230 (1979)

Latha, S., Mathew, M.D., Parameswaran, P., Rao, K.B.S., Mannan, S.L.: Thermal creep properties of alloy D9 stainless steel and 316 stainless steel fuel clad tubes. Int. J. Press. Vessels Piping 85(12), 866–870 (2008)

Mannan, S.L., Chetal, S.C., Raj, R., Bhoje, S.B.: Selection of materials for prototype fast breeder reactor. Trans. Indian Inst. Met. 56, 155–178 (2003)

Mathew, M.D.: Evolution of creep resistant 316 stainless steel for sodium cooled fast reactor applications. Trans. Indian Inst. Met. 63(2–3), 151–158 (2010)

Mathew, M.D., Sasikala, G., Rao, K.B.S., Mannan, S.L.: Influence of carbon and nitrogen on the creep properties of type 316 stainless steel at 873 K. Mater. Sci. Eng. A 148(2), 253–260 (1991)

Mathew, M.D., Laha, K., Ganesan, V.: Improving creep strength of 316L stainless steel by alloying with nitrogen. Mater. Sci. Eng. A 535, 76–83 (2012)

Monkman, F.C., Grant, N.J.: An empirical relationship between rupture life and minimum creep rate in creep rupture tests. Proc. ASTM 56, 91–103 (1956)

Park, J.G., Lee, D.Y.: Creep behavior of AISI 316 stainless steel above 0.5 TM. Scr. Metall. Mater. 29(5), 595–598 (1993)

Phaniraj, C., Nandagopal, M., Mannan, S.L., Rodriguez, P., Kashyap, B.P.: Analysis of first order kinetics for tertiary creep in AISI 304 stainless steel. Acta Mater. 44(10), 4059–4069 (1996)

Phaniraj, C., Choudhary, B.K., Rao, K.B.S., Raj, B.: Relationship between time to reach Monkman–Grant ductility and rupture life. Scr. Mater. 48(9), 1313–1318 (2003)

Praveen, C., Christopher, J., Ganesan, V., Reddy, G.P., Sasikala, G., Albert, S.K.: Constitutive modelling of transient and steady state creep behaviour of type 316LN austenitic stainless steel. Mech. Mater. 137, 103–122 (2019)

Rabotnov, Y.N.: Creep Problems in Structural Members p. 419. North-Holland, Amsterdam (1969)

Reddy, G.P., Mariappan, K., Kannan, R., Sandhya, R., Sankaran, S., Rao, K.B.S.: Effect of strain rate on low cycle fatigue of 316LN stainless steel with varying nitrogen content: Part-II fatigue life and fracture. Int. J. Fatigue 81, 309–317 (2015)

Sauza, D.J., Dunand, D.C., Seidman, D.N.: Microstructural evolution and high-temperature strength of a \(\gamma \) (fcc)/\(\gamma \)’(L12) Co–Al–W–Ti–B superalloy. Acta Mater. 174, 427–438 (2019)

Sundararaman, D., Shankar, P., Raghunathan, V.S.: Electron microscopic study of Cr2N formation in thermally aged 316LN austenitic stainless steels. Metall. Mater. Trans. A 27(5), 1175–1186 (1996)

Vanaja, J., Laha, K., Mythili, R., Chandravathi, K.S., Saroja, S., Mathew, M.D.: Creep deformation and rupture behaviour of 9Cr–1W–0.2V–0.06Ta reduced activation ferritic–martensitic steel. Mater. Sci. Eng. A 533, 17–25 (2012)

Wang, M., Sun, H., Zheng, W., Zhou, Z.: Creep behavior of an alumina-forming austenitic steel with simple alloy design. Mater. Today Commun. 25, 101303 (2020)

Werner, E.: Solid solution and grain size hardening of nitrogen-alloyed austenitic steels. Mater. Sci. Eng. A 101, 93–98 (1988)

Zhang, Y., Jing, H., Xu, L., Zhao, L., Han, Y., Zhao, Y.: High-temperature deformation and fracture mechanisms of an advanced heat resistant Fe-Cr-Ni alloy. Mater. Sci. Eng. A 686, 102–112 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

According to the continuum creep mechanics approach (Kachanov 1960; Rabotnov 1969), the damage and creep rates formulation are represented in coupled form as

where \(\eta \) and \(\beta \) are the constants. \(\omega \) is the damage variable and \(\dot{\omega }_{0}\) is the characteristic damage rate. With the appropriate boundary conditions, the integration of Eq. (7) is written as

Equation (9) yields

When time (\(t\)) tends to \(t_{r}\), the value of damage variable \(\omega \) would approach 1. From Eq. (10), \(t_{r}\) can be derived as

By substituting Eq. (11) into Eq. (10), the damage variable is represented as

Equation (12) is substituted in Eq. (8) followed by the integration of Eq. (8) with the suitable boundary conditions can be written as

The integration of Eq. (13) is given as

By applying the condition \(t = t_{r}\) and \(\epsilon = \epsilon _{f}\), the creep strain equation (Eq. (14)) takes the form in terms of \(\lambda \)

and the damage tolerance factor \(\lambda \) is obtained as

The final forms of strain and strain rate relationships are given as

and

By imposing the condition i.e. time approaches \(t\)MGD, strain rate approaches steady-state creep rate, Eq. (18) can be written as

Equations (18) and (19) have been used in the present analysis to describe the creep behavior and the estimation of \(f\)CDM value as given by Eq. (6) and Eq. (5), respectively.

Rights and permissions

About this article

Cite this article

Ganesan, V., Praveen, C., Christopher, J. et al. Creep behavior of nuclear grade 316LN austenitic stainless steel at 873 K and 923 K. Mech Time-Depend Mater 26, 593–610 (2022). https://doi.org/10.1007/s11043-021-09502-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-021-09502-3