Abstract

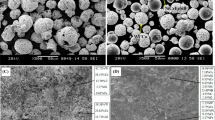

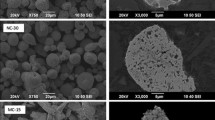

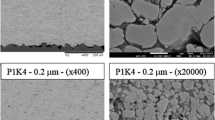

High-velocity oxy-fuel (HVOF)-sprayed coatings have performed exceptionally well in low-energy particle impact wear and are accepted worldwide. However, their application for high-energy particle impact wear (HEPIW) requires a different approach and more efforts. HVOF-coating systems typically use WC-Co, WC-Co-Cr, WC-Ni-Cr, and FeCrAlY-Cr3C2 powders. WC-Co-Cr powders are preferred when there is a high demand for corrosion resistance. WC-10Co-4Cr coating powder has been selected in the current study. To improve coating properties such as microhardness, fracture toughness, and HEPIW resistance, a new approach of surface treatment with robotically controlled high-power diode laser (HPDL) is attempted. The robotically controlled HVOF-coating deposition and laser surface treatment were monitored using real-time diagnostic control. The HPDL-treated coating has been compared with “as-sprayed” HVOF coating for HEPIW resistance, fracture toughness, microhardness and microstructure. The coating characteristics and properties after laser surface treatment have improved many times compared with “as-sprayed” HVOF coating. This is due to the elimination of pores in the coating and formation of a metallurgical bond between coating and substrate. This new development opens up a possibility of using such laser treatments in specialized areas where HEPIW damages are acute. The fracture toughness and HEPIW resistance along with optical micrographs of HPDL-treated and untreated HVOF coatings are discussed and reported in this article. HEPIW resistance is observed to be proportional to the product of fracture toughness and microhardness of the HVOF coating.

Similar content being viewed by others

References

B.S. Mann and V. Arya, Abrasive and Erosive Wear Characteristics of Plasma Nitriding and HVOF Coatings: Their Application in Hydro Turbines, Wear, 2001, 249, p 354–360

B.S. Mann, High-Energy Particle Impact Wear Resistance of Hard Coatings and Their Application in Hydro turbines, Wear, 2000, 237, p 140–146

R.J.K. Wood, Material selection for reducing erosive damage to valves, International Conference on Valves and Actuators—Application and Development, Manchester, UK, Sept. 1994, p 19–21

D.W. Wheeler and R.J.K. Wood, Erosion of Hard Surface Coatings for use in Offshore Gate Valves, Wear, 2005, 258, p 526–536

J.I. Cofer IV, J.K. Reinker, and W.J. Sumner, Advances in Steam Path Technology, GE Power Systems, GER-3713 E, Schenectady, NY

E.R. Buchanan, An overview of Erosion Resistant Coatings for Steam Path Surfaces, Turbo Machinery International, 1987, 28(1), p 25–28

B.S. Mann, Solid Particle Erosion and Protective Layers for Steam Turbine Blading, Wear, 1999, 224, p 8–12

A. Hamed, W. Tabakoff, and R. Wenglarz, Erosion and Deposition in Turbomachinery, J. Propuls. Power, 2006, 22(2), p 350–360

B.S. Mann, V. Arya, A.K. Maiti, M.U.B. Rao, and P. Joshi, Corrosion and Erosion Performance of HVOF/TiAlN PVD Coatings and Candidate Materials for High-Pressure Gate Valve Application, Wear, 2006, 260, p 75–82

R.J.K. Wood, B.G. Mellor, and M.L. Binfield, Sand Erosion Performance of Detonation Gun Applied Tungsten Carbide/Cobalt-Chromium Coatings, Wear, 1997, 211, p 70–83

B.S. Mann, V. Arya, and P. Joshi, Advanced High-Velocity Oxygen Fuel Coating and Candidate Materials for Protecting LP Steam Turbine Blades against Droplet Erosion, J. Mater. Eng. Perform., 2005, 14(4), p 487–494

S. de Palo, M. Mohanty, H. Marc-Charles, and M. Dorfman, Fracture Toughness of HVOF Sprayed WC-Co Coatings, Therm. Spray Surf. Eng. Appl., 2000, 5, p 245–250

H.L. de Villiers Lovelock, Powder/Processing/Structure Relationship in WC-CO Thermal Spray Coatings: A Review of Published literature, J. Therm. Spray Technol., 1998, 7(3), p 357–373

R. Schwetzke and H. Kreye, Microstructure and Properties of Tungsten Carbide Coatings Sprayed with various High Velocity Oxygen Fuel Spray Systems, J. Therm. Spray Technol., 1999, 8(3), p 433–438

J.A. Browning, Viewing the Future of High Velocity Oxy Fuel (HVOF) and High Velocity Air Fuel (HVAF), J. Therm. Spray Technol., 1999, 8(3), p 351–356

H.L. de Villiers Lovelock, P.W. Richter, J.M. Benson, and P.M. Young, Parameter Study of HP/HVOF Deposited WC-Co Coatings, J. Therm. Spray Technol., 1998, 70, p 99–107

B.S. Mann and V. Arya, HVOF Coating and Surface Treatment for Enhancing Droplet Erosion Resistance of Steam Turbine Blades, Wear, 2003, 254, p 652–667

B.S. Mann, V. Arya, B.K. Pant, and M. Agarwal, High Power Diode Laser Surface Treatment to Minimize Droplet Erosion of Low Pressure Steam Turbine Moving Blades, J. Mater. Eng. Perform., 2009, 18(7), p 990–998

B.K. Pant, V. Arya, and B.S. Mann, Cavitation Erosion Characteristics of Nitrocarburised and HPDL Treated Martensitic Stainless Steels, J. Mater. Eng. Perform., 2012, 21(6), p 1051–1055

B.S. Mann, V. Arya, and B.K. Pant, Cavitation Erosion Behaviour of HPDL Treated TWAS Coated Ti6Al4V Alloy and Its Similarity with Water Droplet Erosion, J. Mater. Eng. Perform., 2012, 21(6), p 849–853

R. Schwetzke, and H. Kreye, Cavitation Erosion of HVOF Coatings, Conf. Proc. NTSC, 96, C.C. Brendt, Ed., ASM International, Materials Park, 1996, p 153–158

B.S. Mann, V. Arya, and B.K. Pant, Enhanced Erosion Protection of TWAS Coated Ti6Al4V Alloy Using Boride Bond Coat and Subsequent Laser Treatment, J. Mater. Eng. Perform., 2011, 20(6), p 932–940

C.T. Kwok, H.C. Man, and F.T. Cheng, Cavitation Erosion and Pitting Behavior of Laser Surface Melted Martensitic Stainless Steel UNSS 42000, Surf. Coat. Technol., 2000, 126, p 238–255

Acknowledgments

The authors are thankful to the management of BHEL Corporate R&D, Hyderabad for giving an opportunity to perform research in this area. Thanks are due to all the colleagues of the Centre of Excellence for Surface Engineering, without whose cooperation, it would not have been possible to achieve excellence in this area. Thanks are also due to Dr. C. Bhasker for his useful discussions on this subject and to the site engineers at the Naptha Jakhri, Vishnuprayag, Bhawa, Shanan, and Dehar Hydroelectric projects for providing the data on the performance of HVOF-coated components.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mann, B.S., Arya, V. & Pant, B.K. High-Power Diode Laser Surface Treated HVOF Coating to Combat High Energy Particle Impact Wear. J. of Materi Eng and Perform 22, 1995–2004 (2013). https://doi.org/10.1007/s11665-013-0475-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0475-5